China Extra Large Washer Manufacturer, Supplier, Factory

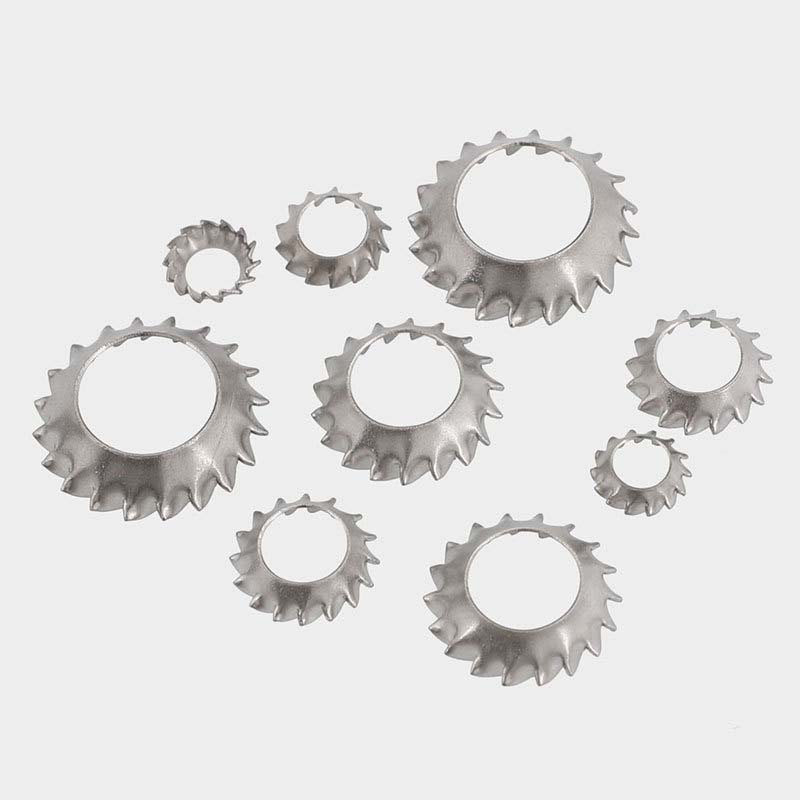

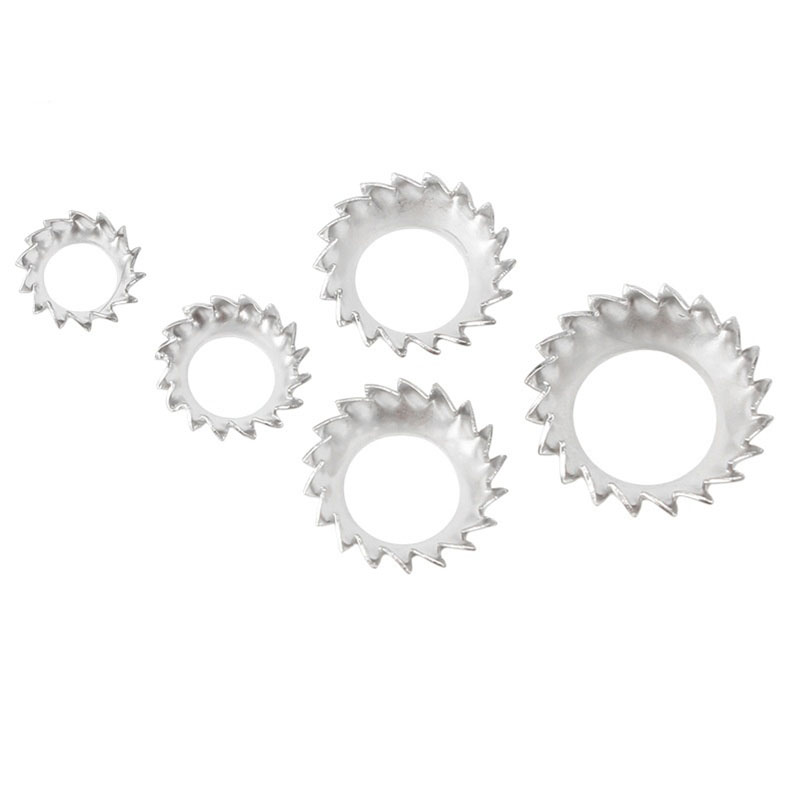

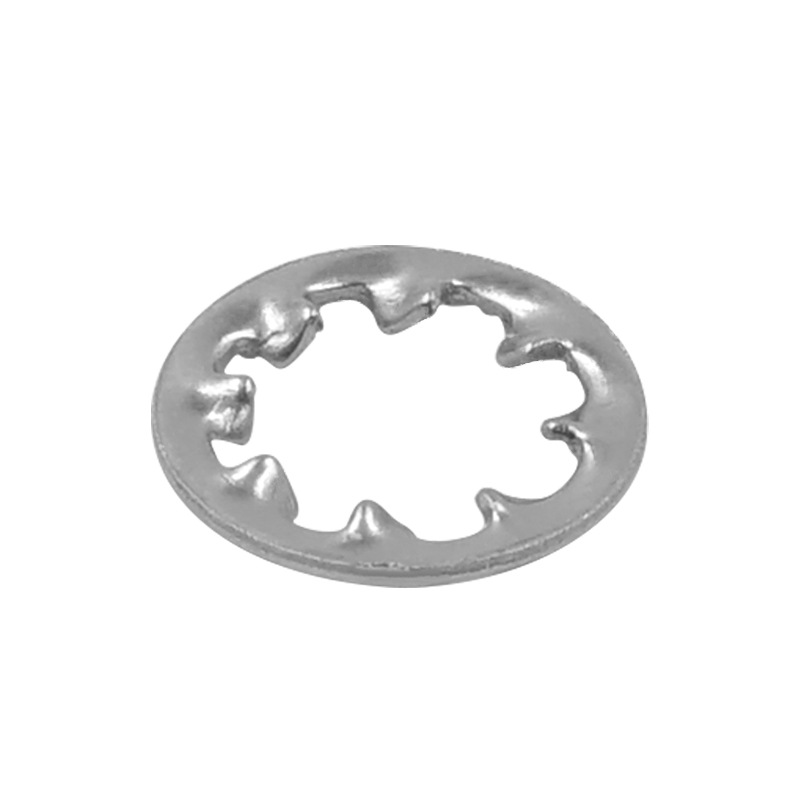

When securing large-scale industrial equipment, the reliability of every component is crucial. While standard washers like Internal Teeth Lock Washers or Light Type Single Coil Spring Lock Washers are excellent for many applications, they are often designed for smaller, less demanding tasks. For massive structures and high-vibration machinery, a more robust solution is required. This is where our Extra Large Washer excels. It is engineered to provide a superior load distribution and clamping force that smaller options, such as a typical Small Washer, simply cannot match. Unlike specialized locking components like the Conical Spring Washer, which is designed to prevent loosening through spring action, the primary function of the Extra Large Washer is to act as a substantial bearing surface, preventing nut embedding and surface damage under extreme pressure.

The Extra Large Washer is a fundamental component for heavy-duty applications where standard-sized fasteners are insufficient. Its significant outer diameter and thickness are specifically designed to distribute immense clamp loads over a wider area, thereby protecting the underlying material from deformation, crushing, or stress cracking. This is critical in industries such as construction, shipbuilding, and large-scale manufacturing, where joint integrity is non-negotiable. The washer's design prioritizes maximum surface contact and stability, ensuring that bolted connections remain secure even under constant dynamic loads and vibrations. The manufacturing process for the Extra Large Washer employs high-grade materials and precise machining to guarantee consistent performance and durability in the most challenging environments.

- Material: High-Carbon Steel / 304 Stainless Steel / 316 Stainless Steel

- Surface Finish: Plain, Zinc Plated, Hot-Dip Galvanized

- Standards: Compliant with ASME B18.22.1, DIN 125, and other international specifications.

- Hardness: Varies by material, typically HRB 70-100 for steel.

| Nominal Size (Bolt Diameter) | Inside Diameter (ID) | Outside Diameter (OD) | Thickness |

|---|---|---|---|

| 1" | 1.0625 in | 2.500 in | 0.134 in |

| 1 1/4" | 1.3125 in | 3.125 in | 0.148 in |

| 1 1/2" | 1.5625 in | 3.750 in | 0.165 in |

| 2" | 2.0625 in | 5.000 in | 0.188 in |

Hot Products

Continuous Thread Studs Coarse Teeth

Continuous thread studs coarse teeth is suitable for projects that require firm and quick connections. These stud threads run through and have thick teeth, making it easy to screw in materials such as wood or thick metal. The inventory of Xiaoguo® factory is sufficient.Cross Recessed Raised Countersunk Head Wood Screws

Baoding Xiaoguo Intelligent Equipment Co., LTD. was set up formally in 2012, as one of the professional China Cross recessed raised countersunk head wood screws manufacturer and China Cross recessed raised countersunk head wood screws factory, we are strong strength and complete management. Also, we have own exporting license. We mainly deal in making a series of Cross recessed raised countersunk head wood screws and so on. We stick to the principal of quality orientation and customer priority, we sincerely welcome your letters, calls and investigations for business cooperation. We assure you of our high quality services at all time.Hexagon Weld Nuts With Flange

Xiaoguo® was set up formally in 2016, as one of the professional China Welded nut manufacturer and China Welded nut factory, we are strong strength and complete management. Also, we have own exporting license. We mainly deal in making a series of Hexagon weld nuts with flange and so on. We stick to the principal of quality orientation and customer priority, we sincerely welcome your letters, calls and investigations for business cooperation. We assure you of our high quality services at all time.T shaped square neck bolt

The T shaped square neck bolt is renowned for its outstanding performance and stability. The bolts produced by Xiaoguo® manufacturer can provide long-lasting and firm support. We offer fast delivery of inventory items. Even if you urgently need them, we can still meet your demands.Hex Head Lag Screws With Fit Neck

Baoding Xiaoguo Intelligent Equipment Co., LTD. is Hex head lag screws with fit neck manufacturer and supplier in China who can wholesale Slotted pan head screws. The company will make reasonable plans according to the customized needs of customers.Shaft Pin Without Head

Shaft pin without head is different from the ones with heads. The headless ones sit flatter. They're great for tight spots where you don't want anything sticking out too much.Rigorous quality control at Xiaoguo® ensures every fastener exceeds durability and performance expectations.