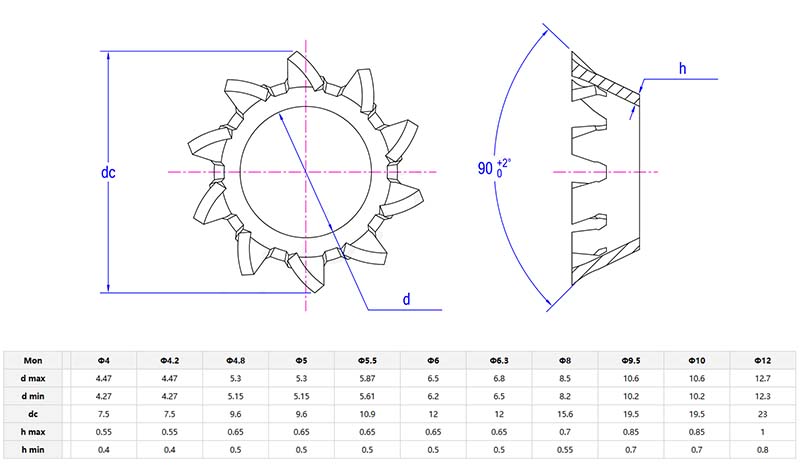

Cone Lock Washer

Send Inquiry

The cone lock washer is made from either high-carbon steel or stainless steel. These materials make it strong and less likely to rust. When heat-treated, some versions become harder (reaching 40-50 on the HRC scale), making them better for heavy-duty use. Stainless steel types (like Grade 304 or 316) are good for wet environments or chemical areas because they resist rust better.

The steel has some springiness, so the cone lock washer can flex without breaking. This helps it stay tight even when temperatures change. They're made with precise stamping to keep thickness consistent and serrations at the right depth for better grip. These features let it work in temperatures from freezing cold (-50°C) to pretty hot (300°C).

Applications

The cone lock washer is a must-have in places like car engines, airplane parts, and construction machines, where stopping vibration is super important. It keeps bolted connections tight in things like pumps, turbines, and rail systems, which helps avoid major breakdowns. In HVAC setups, it holds compressor mounts steady, and in renewable energy projects (like wind turbines), it keeps everything secure. It’s not just for big industries,even DIY projects use it to fasten furniture or machinery. Engineers like it because it can handle both pushing (axial) and side (radial) forces at the same time, making it a good fit for parts that move or spin a lot.

Advantages

Q: How does the cone lock washer keep things from loosening compared to spring washers?

A: Spring washers rely on up-and-down pressure (axial resistance) to stay tight, but the cone lock washer uses sideways friction. Its sloped sides grip into both the bolt head/nut and the surface it’s attached to, creating a mechanical lock that fights spinning forces and vibrations better. When you tighten the bolt, the taper shape increases the clamping force, making the grip stronger as it’s pulled tight. Tests show tapered lock washers handle back-and-forth loads (cyclic loads) up to 40% better than spring washers. For really important connections, you can also use thread-locking glue along with them for extra security.