China Conical Spring Washer Manufacturer, Supplier, Factory

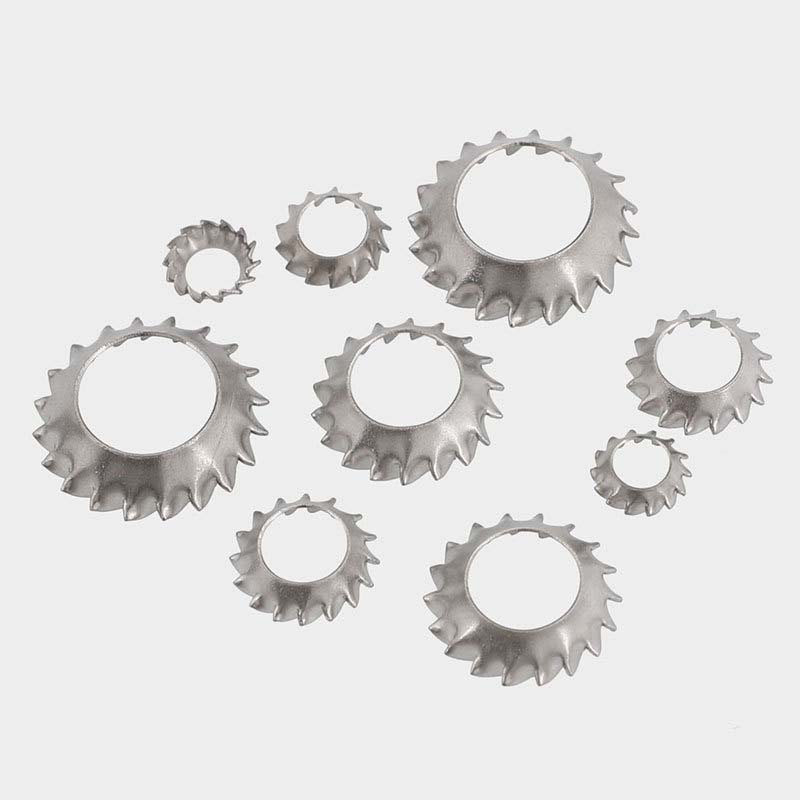

In the world of industrial fastening, ensuring secure and reliable connections is paramount. To achieve this, various specialized washers are employed, each designed for specific applications. Among these, the conical spring washer stands out for its unique ability to maintain tension and prevent loosening under dynamic loads. For applications requiring internal locking mechanisms, Internal Teeth Lock Washers offer excellent resistance to rotation. When a lighter load and compact design are needed, consider our Light Type Single Coil Spring Lock Washers. For projects involving large-scale structures or oversized bolts, an Extra Large Washer provides the necessary bearing surface. Conversely, precision instruments and compact assemblies often require a Small Washer to function effectively. Each of these components plays a vital role in a comprehensive fastening system.

The conical spring washer is engineered to provide a consistent and robust spring action. Its distinctive conical (or Belleville) shape allows it to deflect under load, storing energy and exerting a continuous counter-force. This action compensates for thermal expansion, vibration, and material relaxation that can lead to joint failure. The design of the conical spring washer ensures that even after prolonged use and exposure to stress, it returns to its original shape, maintaining the clamp load. This makes it an indispensable component in applications ranging from automotive and aerospace to heavy machinery and construction, where safety and durability are non-negotiable.

Key Features and Specifications

- Material: Typically made from high-carbon steel (AISI 1070/1095) or stainless steel (AISI 302/304/316), offering excellent spring properties and corrosion resistance.

- Function: Provides a high spring rate in a small axial space, maintaining preload and preventing loosening caused by vibration.

- Load Bearing: Designed to handle significant static and dynamic loads without permanent deformation.

- Temperature Range: Suitable for operations within a wide temperature spectrum, from -20°C to +250°C, depending on the material.

- Surface Finish: Often available with zinc plating, phosphate coating, or plain oil finish for enhanced durability and performance.

Detailed Product Parameters

| Nominal Size (mm) | Outside Diameter (mm) | Inside Diameter (mm) | Thickness (mm) | Load at Deflection (N) | Standard |

|---|---|---|---|---|---|

| M4 | 8.0 | 4.2 | 0.8 | 510 | DIN 6796 |

| M6 | 11.5 | 6.2 | 1.2 | 1120 | DIN 6796 |

| M8 | 15.0 | 8.2 | 1.6 | 2100 | DIN 6796 |

| M10 | 19.0 | 10.2 | 2.0 | 3400 | DIN 6796 |

| M12 | 22.0 | 12.2 | 2.5 | 5100 | DIN 6796 |

Hot Products

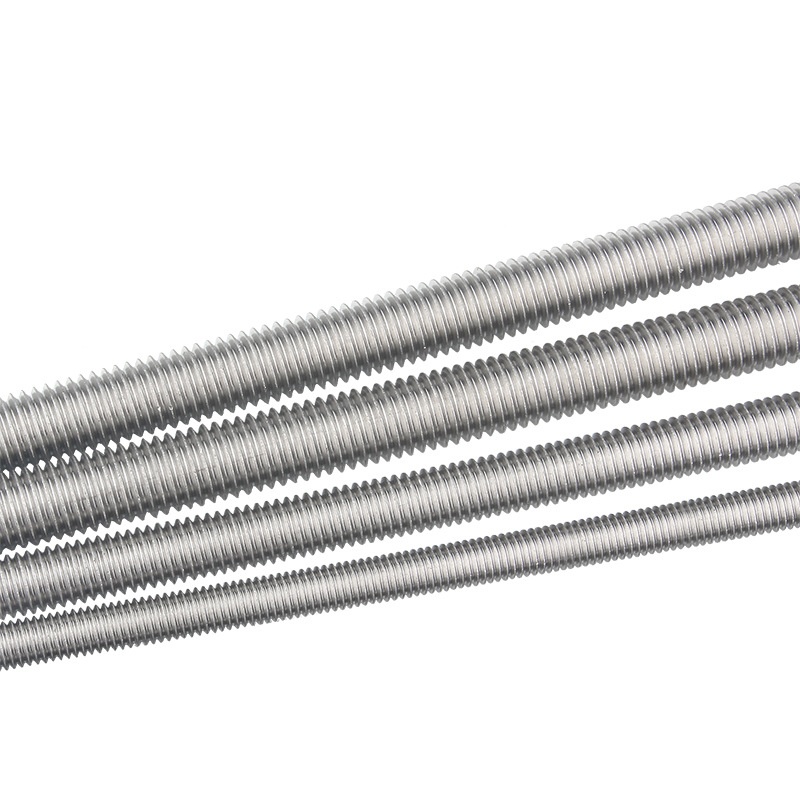

High Precision Threaded Rod

High Precision Threaded Rods are used as fully threaded studs for connecting components or providing adjustable anchor points. Xiaoguo's high-precision threaded rods are engineered to meet the latest high-precision threaded rod specifications, so you can purchase them with confidence.Application Specific Bent spring

International partners rely on Xiaoguo's expertise.For innovative Application Specific Bent spring solutions that combine flexibility with durability, Custom-engineered for specific tasks, a Application-Specific Bent spring offers a tailored solution that standard compression or extension springs cannot provide.Corrosion Resistant Round Head Bolt

The corrosion resistant round head bolts are coated with things like zinc plating or hot-dip galvanizing to make them last longer and resist rust,perfect for outdoor use or wet environments.Xiaoguo® has a wide variety of fasteners,stainless steel, carbon steel and special alloys. We will meet any needs of our customers.Double Tube Fixing Clamps

The balanced design of the Double Tube Fixing Clamps ensures even force distribution and minimizes stress concentration points. The European and North American markets are the main destinations for the small country's exports, and XIAOGUO® fasteners meet strict DIN/ANSI standards.Heavy Duty Stud Bolts

Heavy Duty Stud Bolts are the preferred fastener in industries like oil and gas for assembling flanged piping connections, and Xiaoguo®, a professional manufacturer, specializes in producing a comprehensive range of high-quality screws, bolts, and nuts.Cylindrical countersunk head nib bolts

The nib of Cylindrical countersunk head nib bolts, engaged in its recess, helps transmit torque/shear forces between the bolt head and the part, supplementing the friction under the head. Xiaoguo®'s bolts are strictly in accordance with the DIN 792-1976 standard, and our quality is strictly controlled. We have a large inventory and can deliver goods quickly.