China Small Washer Manufacturer, Supplier, Factory

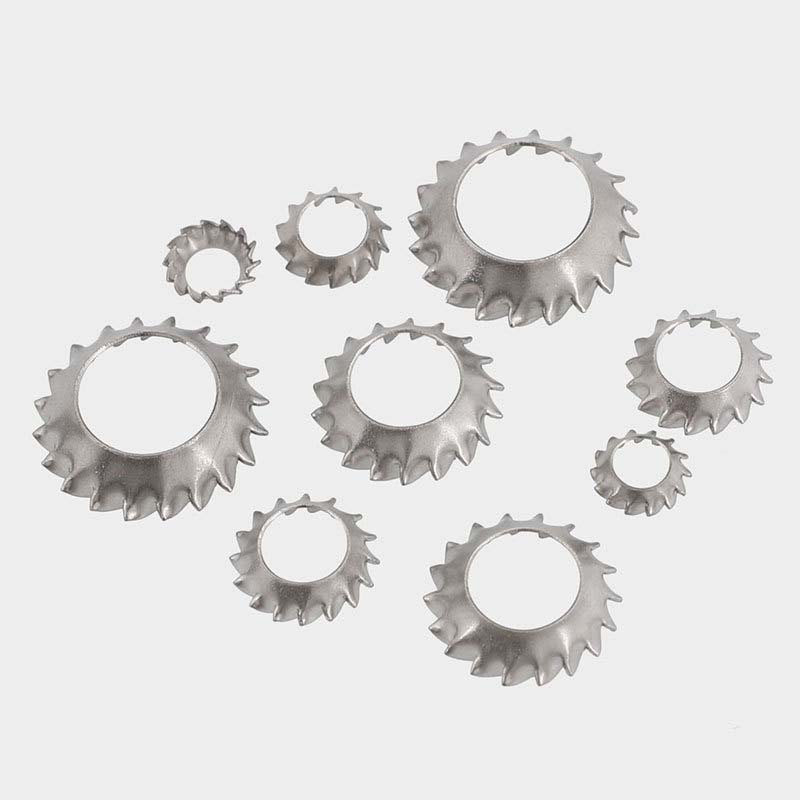

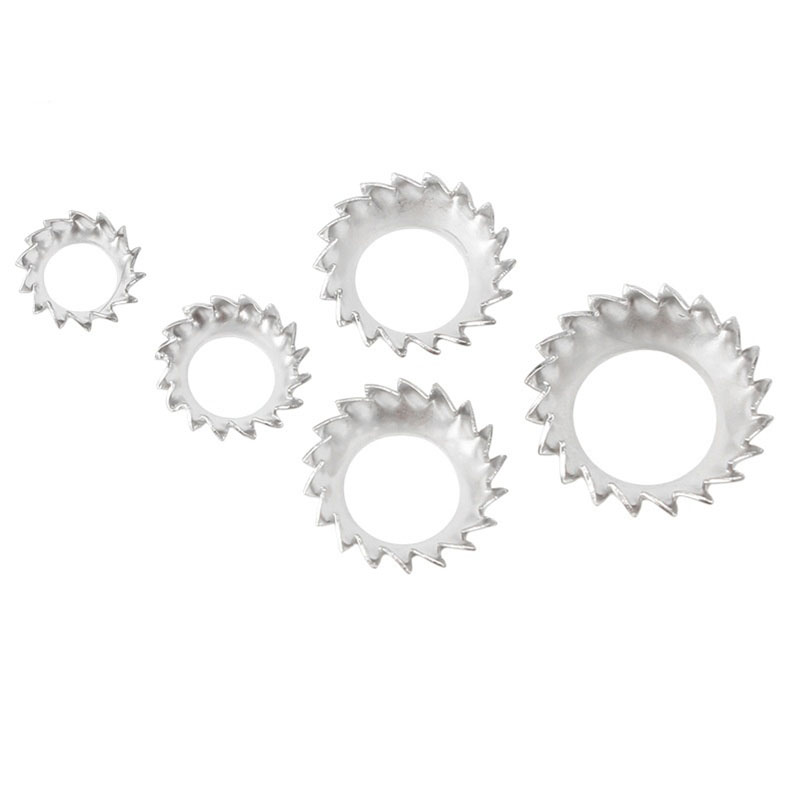

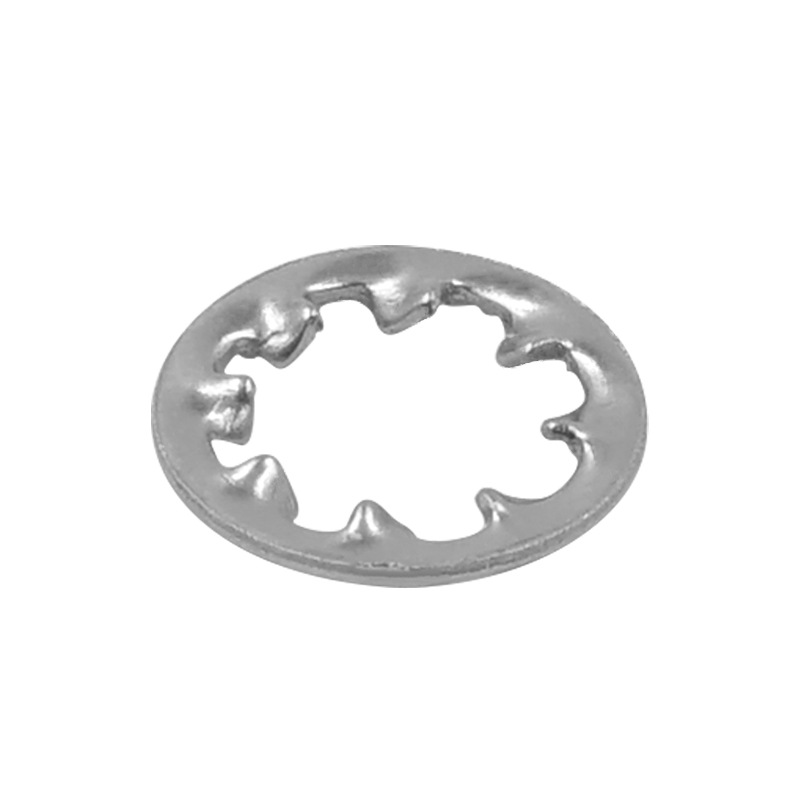

In high-performance applications, having the right washers is critical for ensuring long-term reliability and preventing mechanical failure. Small washers may seem simple, but they play an indispensable role in distributing load, preventing loosening, and compensating for thermal expansion. For instance, when you need to maintain tension in a bolted assembly under dynamic loads, Internal Teeth Lock Washers provide excellent resistance to rotation and vibration. Their internal teeth bite into the material, creating a secure lock. Meanwhile, for applications requiring a lighter preload and vibration damping, our Light Type Single Coil Spring Lock Washers offer a cost-effective and reliable solution. When you're dealing with oversized bolt holes or need a larger bearing surface, our Extra Large Washer is engineered to prevent pull-through and reduce surface pressure. And for the highest tension and spring action in demanding environments, the Conical Spring Washer is unparalleled, maintaining clamp force even under significant stress and thermal cycling. Choosing the correct small washer directly impacts the safety, performance, and longevity of your equipment.

The Small Washer is engineered with precision to meet the highest industrial standards. Its compact design belies its significant role in maintaining the integrity of a bolted joint. Below are the detailed specifications and technical data for the standard Small Washer.

Small Washer: Standard Specifications

- Material: Carbon Steel, Grade 1050

- Surface Finish: Plain, Zinc Plated, or Phosphated

- Standards: Compliant with ASME B18.21.1, DIN 127, and ISO 7089

- Operating Temperature: -20°C to +120°C (Standard Finish)

| Nominal Size (M) | Inside Diameter (mm) | Outside Diameter (mm) | Thickness (mm) | Approx. Weight per 1000 pcs (kg) |

|---|---|---|---|---|

| M3 | 3.2 | 7.0 | 0.5 | 0.12 |

| M4 | 4.3 | 9.0 | 0.8 | 0.25 |

| M5 | 5.3 | 10.0 | 1.0 | 0.40 |

| M6 | 6.4 | 12.0 | 1.6 | 0.95 |

| M8 | 8.4 | 16.0 | 1.6 | 1.70 |

Mechanical Properties

| Material Grade | Hardness (HV) | Tensile Strength (MPa) | Proof Load (MPa) |

|---|---|---|---|

| Carbon Steel 1050 | 200 - 300 | 650 min | 500 |

| Stainless Steel A2 | 210 - 280 | 500 min | 400 |

Hot Products

Heavy Hex Flat Nuts

Strong steel heavy hex flat nuts with a flat washer-like surface to spread pressure evenly.Xiaoguo® factory provides various fastener products, including bolts, nuts, washers, etc.Hexagonal Turnbuckle Nut

Hexagonal turnbuckle nuts are suitable for everything from small machine building to sports equipment assembly. We use high-quality materials to ensure that the nuts are durable and can withstand different environments.Xiaoguo® can meet your needs for hexagonal turnbuckle nut.120 Countersunk Head Semi Tubular Rivets Screws Ferrous Metal

Baoding Xiaoguo Intelligent Equipment Co., LTD., specializes in the wholesaling and manufacture of high-end rivets screws many years,Our Xiaoguo rivets screws are affordable and of good quality and are well known in the European market.As a professional rivets screws manufacturer, you can rest assured to buy rivets screws from our factory and Xiaoguo will offer you the best after-sale service and timely delivery.We look forward to 120 Countersunk Head Semi Tubular Rivets Screws Ferrous Metal in China.Acorn Hexagon Nuts

High quality Acorn Hexagon Nuts is offered by China manufacturer Xiaoguo®. Buy Acorn Hexagon Nuts which is of high quality directly.The role of the cap is to tighten the exposed part of the outer cover to prevent moisture or some other corrosive substances from entering the inside so as to play the role of rust prevention, thereby improving the service time of itself and the connecting parts.Multi Material Core Penetrating Rivet

Multi Material Core Penetrating Rivet features a unique design: its mandrel, when pulled, expands and penetrates into the rivet's own shell, creating a large blind-side footprint. The manufacturer behind this innovative fastening solution, Xiaoguo®, upholds a company culture that emphasizes innovation, responsibility, and customer satisfaction above all else.Stainless Steel Round Self Clinching Nut

Xiaoguo handles export documentation and logistics efficiently.The stainless steel round self clinching nut is a specialized fastener designed for permanent, high-strength blind-side fastening applications where traditional nuts cannot be accessed.