T shaped square neck bolt

Send Inquiry

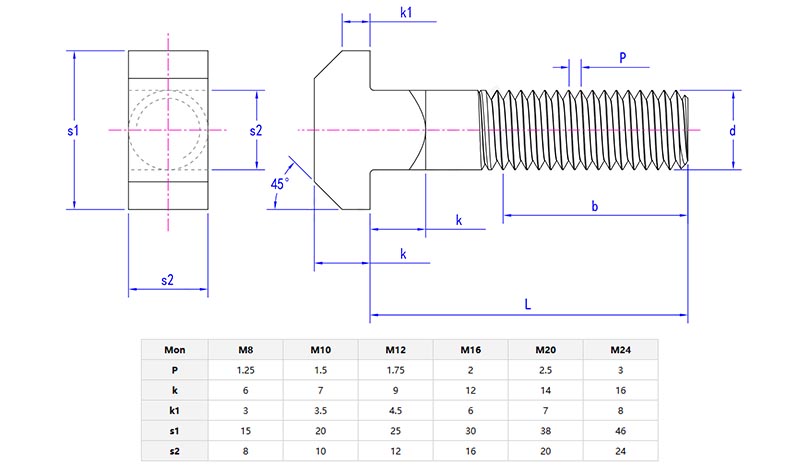

The head of the T shaped square neck bolt is T-shaped, with a square neck connected below it, followed by a threaded screw part. Produced strictly in accordance with the standard of JB/T 1709-1991, it can meet different connection requirements.

Product detail

The bolt can be used to build an adjustable workstation frame. They can slide into the extrusion grooves at any position. Add the bracket and tighten it. The bolt neck can be immediately clamped to keep the component square. The layout can be reconfigured without drilling new holes.

Insert the T shaped square neck bolt into the T-shaped slot of the display stand frame. The square neck design prevents the bolts from rotating during installation. By tightening or loosening the nuts, the positions of the individual components can be adjusted, thus changing the shape and layout of the display stand. The T-shaped head and square neck work together to ensure a stable connection of the display stand and prevent it from shaking easily.

T-shaped square neck bolts can be used to install conveyor belt drive devices, which slide into the frame grooves. When tightening the sprocket bracket, the bolt neck will lock, thus maintaining precise alignment during the tensioning process. The misalignment of the pulley caused by the rotation of the bolts has been eliminated.

Product parameters

Product selling point

The design of the T shaped square neck bolt is very ingenious. The T-shaped head is convenient for positioning and operation. The square neck can prevent the bolt from rotating along with the nut when it is tightened, making the connection more stable. No professional skills are required during installation. Whether it is industrial production or daily life, as long as there is a need for object connection and fixation, it can basically be put to use.