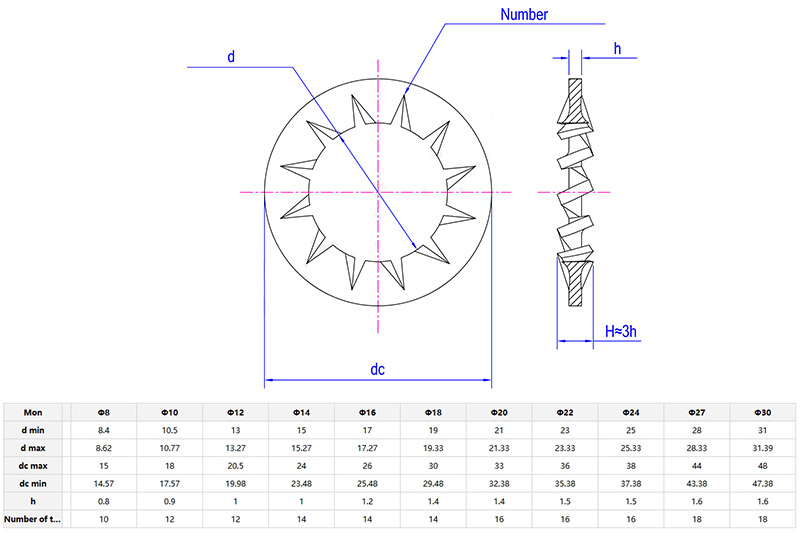

Lock Washer With Internal Teeth

Send Inquiry

Lock washer with internal teeth is a key in setups where vibrations could loosen parts. You’ll see them in engine mounts, transmission systems, pump housings, and heavy machinery brackets. They’re also used in electronics for parts that get shaken around, like in robotics or HVAC units. In construction, they keep structural steel connections tight, and cars use them a lot for wheel hubs and suspension parts. What makes these washers work across so many fields? They hold bolts securely, whether things are moving or not.

Material

Lock washer with internal teeth is made from carbon steel, stainless steel, or alloy metals. These material makes lock washer strong, resistant to rust, and durable. Heat-treated versions (like SAE 1060-1090 steel) are harder (40-50 HRC), so the teeth grip better and don’t wear out as fast.

Stainless steel types, such as 304 or 316, are suitable for locations that are susceptible to rust, such as near water or chemicals.For electrical work or lightweight needs, copper or aluminum versions are used. The material you pick decides how well the lock washer with internal teeth handle pressure and hold up over time,the teeth need to stay sharp to grip surfaces without bending or snapping.

FAQ

Q: Can lock washer with internal teeth replace thread-locking adhesives?

A: Lock washer with internal teeth stop loosening with mechanical grip, while adhesives glue threads together chemically. In really shaky environments, use both to be extra safe. For moderate vibration, the washers alone work fine,no need for chemicals. But if you need a permanent connection that can’t be tampered with, adhesives are better. Just choose based on how much maintenance you’ll need and how much stress the joint will handle.