Tapered Lock Washer

Send Inquiry

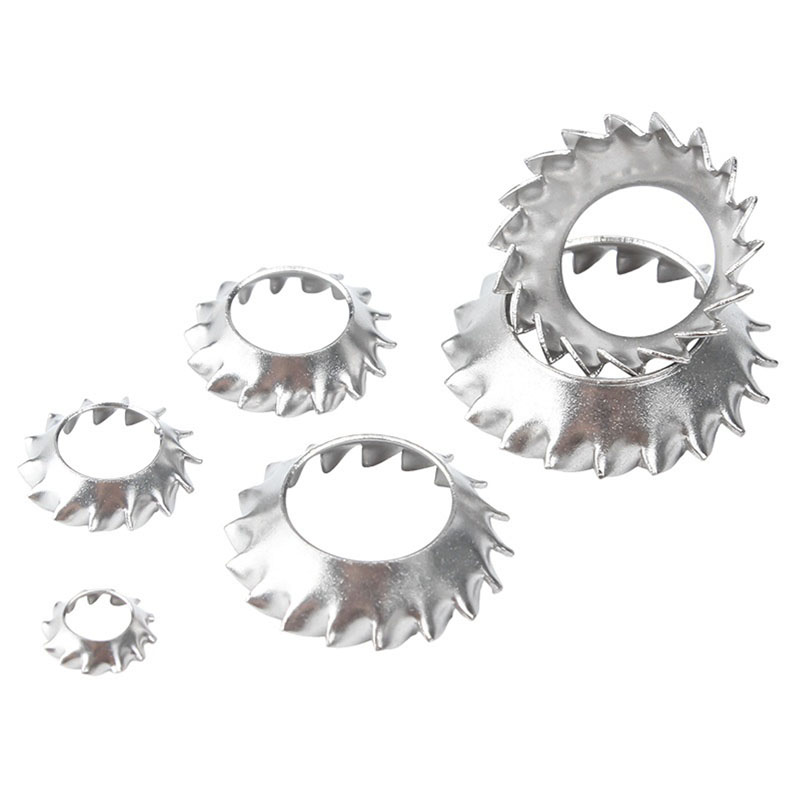

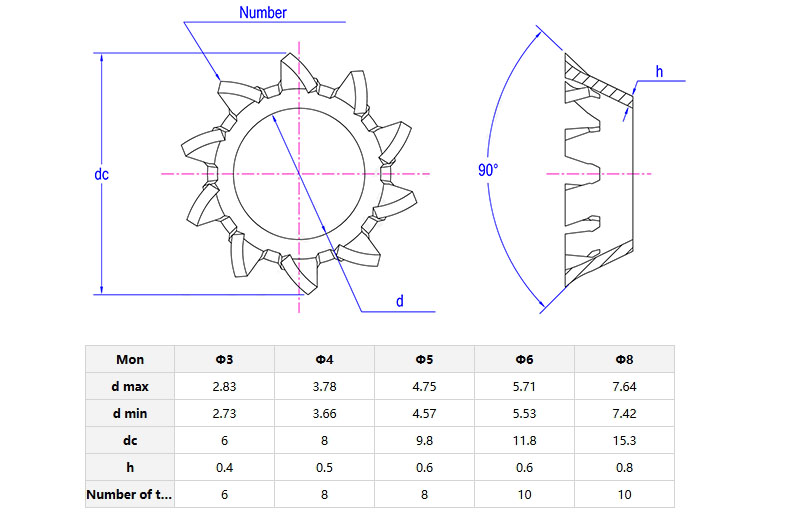

The tapered lock washer is a cone-shaped fastener that is mainly used to prevent the bolt from loosening due to vibration or heavy load. It has small teeth or ridges around it. When installed in the correct position, the ridges will create a stable pressure between the nut and its connecting surface, making the connection more secure, longer and less likely to loosen.

Tapered lock washer works well for heavy machinery, cars, and industrial setups. If things heat up and expand or wear down over time, this washer can adjust to that, making sure the clamping force stays strong.

The use of tapered lock washers eliminates the need for additional parts to secure the connector in the desired position.That makes putting it together easier while still being reliable. It’s made to last, so it’s a key part in any system that needs to resist vibration and keep the same amount of tightness over time.

Features

The tapered lock washer has a built-in self-locking feature that stops slippage, even in really tough conditions. Unlike flat washers, its cone shape lets it grip into the surfaces it’s between, creating friction that fights against spinning forces.

Key benefits include lower maintenance costs, longer service life, and fit for standard bolt sizes. Lightweight and strong construction, easy to install without any special tools.

For industries that place a high premium on safety, Xiaoguo® manufactures tapered lock washers that meet ISO and DIN standards, are of high quality and do not need to be replaced all the time. Businesses can reduce downtime and increase efficiency, making this an economical washers.

Where does the washer work best?

The tapered lock washer works best in shaky or vibrating setups where normal flat washers or spring washers might fail. Its cone shape digs into both the bolt and surface as you tighten it, acting like a wedge to stop loosening,even if things heat up, cool down, or settle over time. You’ll find these in stuff like heavy machines, car engines, airplane parts, or factory gear that handles constant movement. Unlike regular washers, the tapered design keeps the bolt tight by holding pressure better. Just pair it with properly tightened bolts and make sure the surfaces it sits against are clean and flat. Always check if it meets your industry’s specs (like ASTM or DIN) for your project.