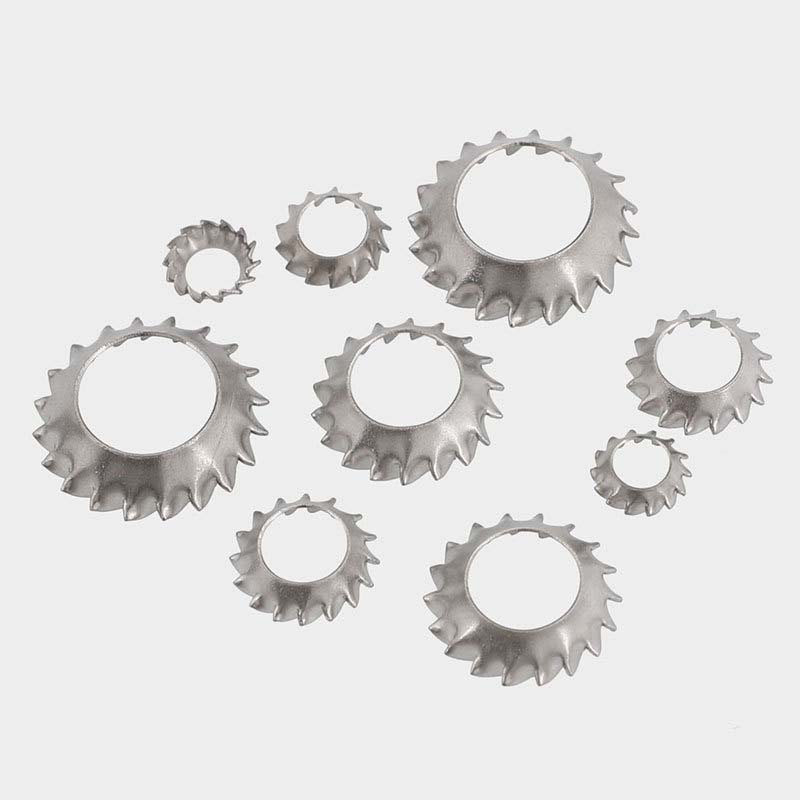

China Internal Teeth Lock Washers Manufacturer, Supplier, Factory

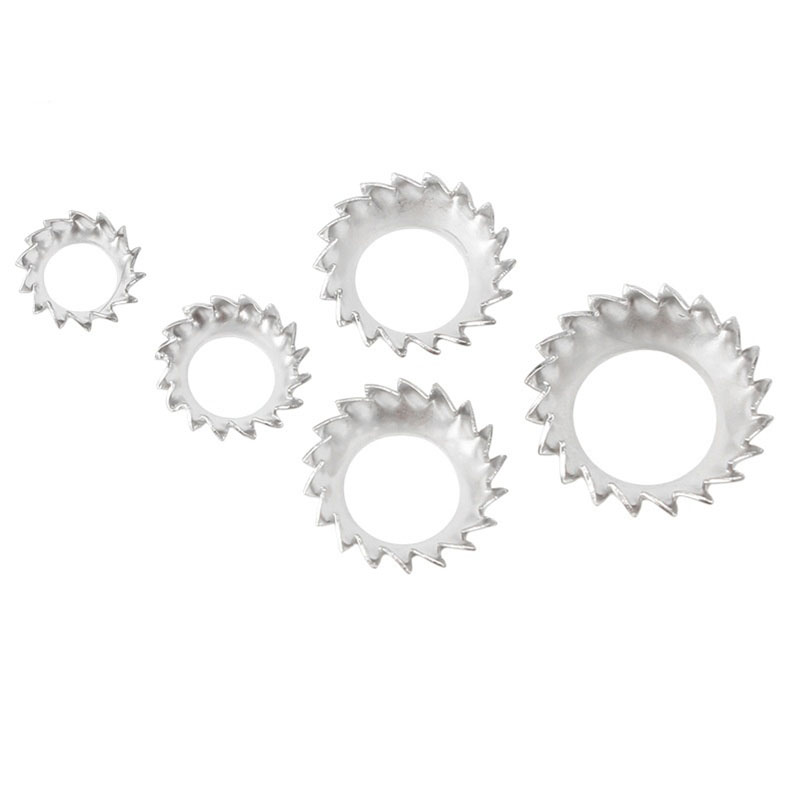

Internal teeth lock washers are essential components for preventing fastener loosening in demanding applications where vibration, thermal cycling, or dynamic loads are present. The unique design, featuring internal teeth that bite into the fastener and bearing surface, provides superior resistance to rotation and maintains consistent clamp load. This makes them an ideal choice for critical assemblies in automotive, aerospace, and heavy machinery. For applications requiring a different locking mechanism, consider our Light Type Single Coil Spring Lock Washers, which offer a helical spring action. When space constraints or specific load distributions are a factor, our range of Extra Large Washer and Small Washer sizes provide the necessary versatility. Alternatively, a Conical Spring Washer can be used to compensate for material settlement and maintain tension under high stress conditions.

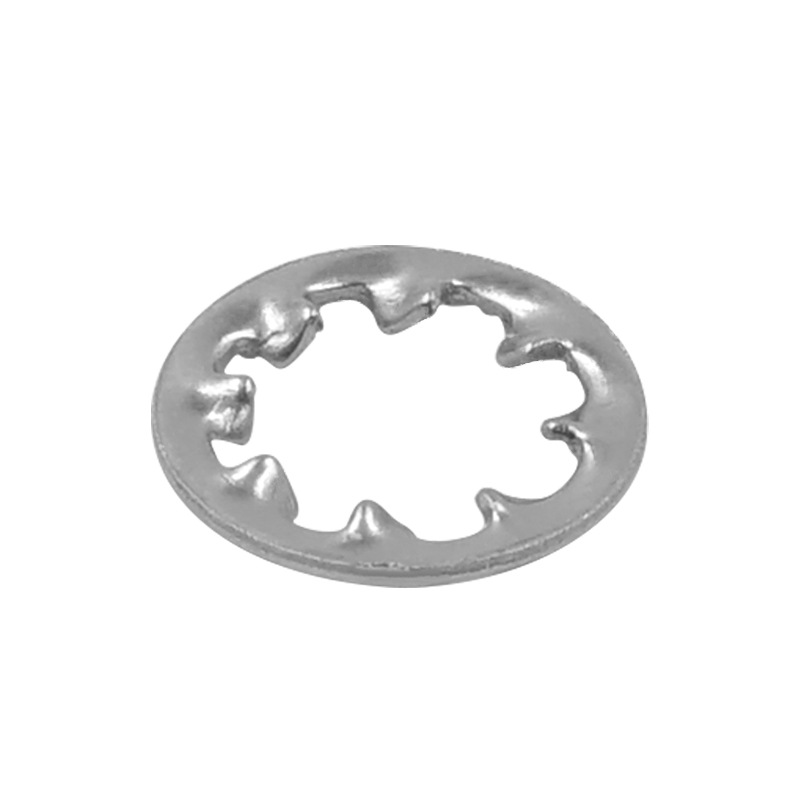

The primary function of an Internal Teeth Lock Washer is to create a high-friction interface that prevents the nut or bolt from rotating loose. The internal teeth are precision-formed and hardened to ensure they effectively dig into the material of both the fastener and the workpiece, without causing excessive damage. This biting action secures the assembly far more reliably than a standard flat washer. Internal Teeth Lock Washers are manufactured from high-carbon steel and often feature a zinc or phosphate coating for corrosion resistance, making them suitable for use in harsh environments. They are designed for repeated use in disassembly and reassembly scenarios, maintaining their locking efficacy over multiple cycles.

Key Specifications of Internal Teeth Lock Washers

- Material: High-Carbon Steel, Stainless Steel 304/316

- Finish: Zinc Plated, Plain, Phosphate Coated

- Hardness: HRC 40-50 (for carbon steel)

- Standards: Compliant with DIN 6797, ANSI B18.21.1

- Temperature Range: -20°F to +450°F (standard finishes)

| Nominal Size (Inches) | Inside Diameter (ID) (Inches) | Outside Diameter (OD) (Inches) | Thickness (Inches) | Approx. Teeth Count |

|---|---|---|---|---|

| #4 | 0.125 | 0.312 | 0.032 | 6 |

| #8 | 0.172 | 0.437 | 0.039 | 8 |

| 1/4 | 0.250 | 0.562 | 0.047 | 10 |

| 3/8 | 0.375 | 0.812 | 0.065 | 12 |

| 1/2 | 0.500 | 1.062 | 0.083 | 16 |

| 5/8 | 0.625 | 1.375 | 0.095 | 20 |

Hot Products

Efficient Lifting Eye Nut

Efficient Lifting Eye Nut: Over the years, Xiaoguo® has built a good reputation among foreign buyers and manufacturers because they always deliver what they promise—quality fasteners and reliable service. Before using an Efficient Lifting Eye Nut, it’s important to check for cracks or damage on the loop or threads, as worn parts can break under heavy loads.Hex Large Flange Nuts

Xiaoguo®'s hex large flange nuts have a wide flange base to better distribute negative pressure and load-bearing force, and the nuts will not crack under pressure. They are used in construction, bridges or heavy machinery.Our factory provides free samples.Wave Single Coil Spring Lock Washer

Wave Single coil spring lock washers solve the problem of thermal expansion, are not easy to loosen, and reinforce other fasteners used with them. They can be used in components in automobiles, aircraft and machines.Xiaoguo® is a professional supplier that always maintains high quality standards and adapts to diverse market demands.Serrated Lock Washer External Teeth For Assembly

The serrated lock washer external teeth for assembly used for assembly can withstand greater pressure and maintain a firm connection. Serrated lock washers are often used to assemble automobiles and mechanical equipment. As a professional washer manufacturer, Xiaoguo® has an on-time delivery rate of 98%.Component Securing Pin

Xiaoguo Company offers discounted prices on Component Securing Pin.The Pin ensures the stability of the assembly structure and is widely used as a basic fastener in various mechanical and electronic products.Feel free to contact us if you're interested.Compatible T Slot Nut

Efficient logistics and reliable on-time delivery—tailored to meet manufacturers’ diverse operational needs—are hallmarks of the Xiaoguo® service.You will commonly find a Compatible T Slot Nut used in machine tools, 3D printers, jig and fixture setups, and modular assembly frames.