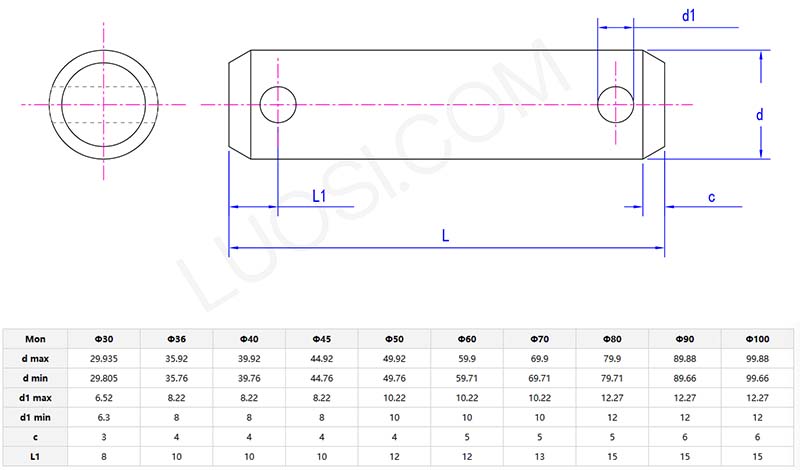

Shaft Pin Without Head

Send Inquiry

Shaft pin without head is available in SAE 8620 alloy steel or AISI 316 stainless steel, offering a balance of strength and weight. The alloy steel version is case hardened (carburized) to a hardness of 60-65 HRC on the outside while retaining a tough core, making it strong on the inside and tough on the outside.The stainless steel version naturally resists rust, so it works well in salty marine environments or around chemicals.

They use a special forging method (grain-flow forging) that aligns the metal’s structure along the pin’s length. This makes it last 40% longer under repeated stress compared to pins made by just machining the metal. Some models have coatings like PTFE or zinc-nickel that cut friction down to 0.08 and make them wear less.

All this material work means the headless pin can handle temperatures from -50°C to 300°C without bending or changing shape.

Advantage

Compared to traditional dowel pins, the shaft pin without head cuts assembly weight by 15-20%. Its cross-sectional shape is designed to boost shear strength,basically, it’s stronger where it counts. Because there’s no head creating stress points, it resists fatigue 35% better when under repeated stress (like in parts that move a lot).

Unlike roll pins, it doesn’t lose shape in high-speed applications,think stuff spinning fast. The no-head design also means you don’t need to drill extra counterbores, saving 18% on machining costs per part. In automated factories, its symmetrical

FAQ

Q: How do shaft pin without head perform under high shear or tensile stress in dynamic environments?

A: Headless shaft pin is designed to withstand high shear and tensile loads, with load ratings typically between 50-150 kN, depending on the material used and the heat treatment process. The headless design evenly distributes stress, reducing the likelihood of failure of pivoting or rotating components. Processes such as quenching and tempering give them better fatigue resistance. If you use them under extreme conditions, you can contact us for test reports (such as load test results or HRC hardness) to ensure that they can work well under the stress conditions specific to your industry.