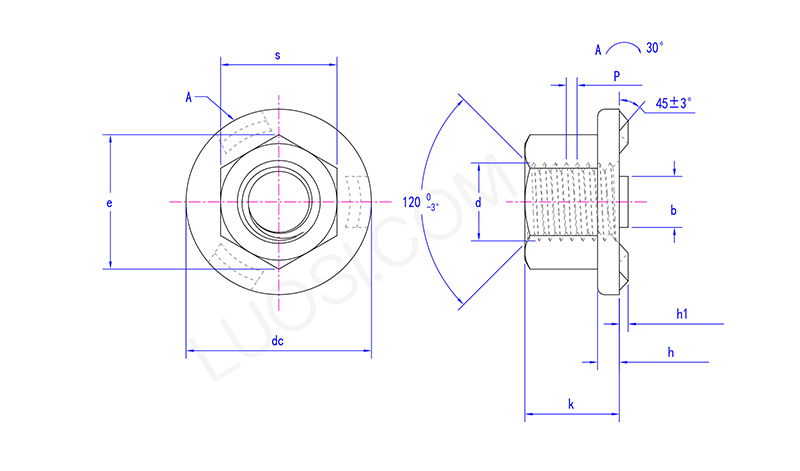

High efficiency Weld hexagon nuts with flange

Send Inquiry

When you need the best rust protection or non-magnetic nuts, high efficiency weld hexagon nuts with flange come in austenitic stainless steels like AISI 304 or 316/L. These types hold up well against rust, chemicals, and high heat. Stainless steel ones work great in places like food processing, pharmaceuticals, marine settings, and really corrosive chemical environments.

| Mon | M5 | M6 | M8 | M10 | M12 | M14 | M16 |

| P | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 |

| h1 max | 0.9 | 0.9 | 1.1 | 1.3 | 1.3 | 1.3 | 1.3 |

| h1 min | 0.7 | 0.7 | 0.9 | 1.1 | 1.1 | 1.1 | 1.1 |

| dc max | 15.5 | 18.5 | 22.5 | 26.5 | 30.5 | 33.5 | 36.5 |

| dc min | 14.5 | 17.5 | 21.5 | 25.5 | 29.5 | 32.5 | 35.5 |

| e min | 8.2 | 10.6 | 13.6 | 16.9 | 19.4 | 22.4 | 25 |

| h max | 1.95 | 2.25 | 2.75 | 3.25 | 3.25 | 4.25 | 4.25 |

| h min | 1.45 | 1.75 | 2.25 | 2.75 | 2.75 | 3.75 | 3.75 |

| b max | 4.1 | 5.1 | 6.1 | 7.1 | 8.1 | 8.1 | 8.1 |

| b min | 3.9 | 4.9 | 5.9 | 6.9 | 7.9 | 7.9 | 7.9 |

| k min | 4.7 | 6.64 | 9.64 | 12.57 | 14.57 | 16.16 | 18.66 |

| k max | 5 | 7 | 10 | 13 | 15 | 17 | 19.5 |

| s max | 8 | 10 | 13 | 16 | 18 | 21 | 24 |

| s min | 7.64 | 9.64 | 12.57 | 15.57 | 17.57 | 20.16 | 23.16 |

Advantage:

The high efficiency weld hexagon nuts with flange does a few important things. It works like a built-in washer, spreading out the load and keeping soft surfaces from getting damaged. It also gives a bigger, steadier area to work with when welding. Most importantly, the flange helps them stay tight way better than regular hex nuts,even when there’s vibration, shocks, or moving loads that might make them loosen up.

Excellent anti-corrosion performance:

Common ways to treat high efficiency weld hexagon nuts with flange are zinc plating—like yellow, blue, or clear,hot-dip galvanizing for tough environments, and dacromet coating. The stainless steel ones (A2/A4) don’t need extra coating; they resist rust on their own.