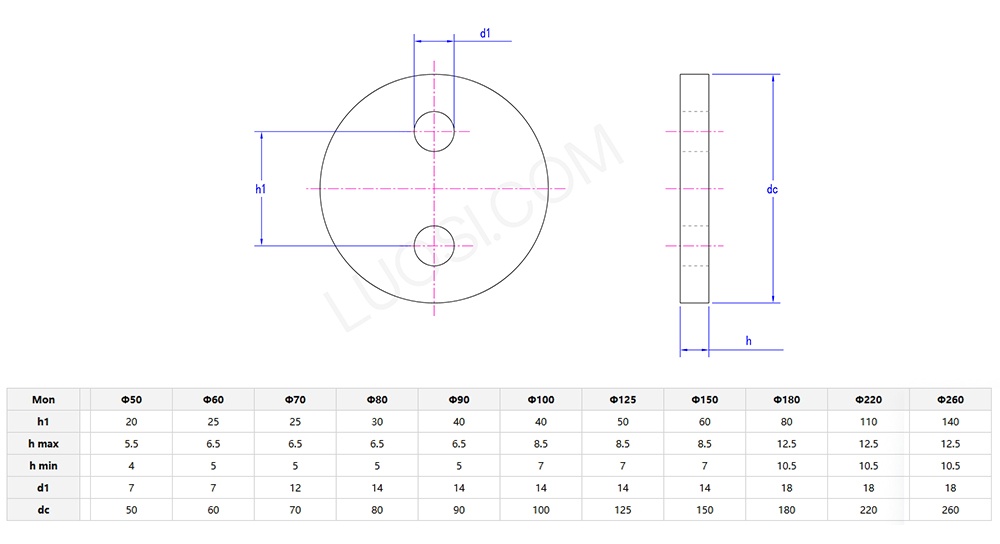

Bolt Secured Shaft End Retaining Ring

Send Inquiry

The bolt secured shaft end retaining ring is more reliable than traditional circlips because of its bolted locking setup, which cuts down on the risk of it popping off. Its split design lets you install it without taking the shaft apart, saving labor costs. It works with existing shafts, so you don’t have to spend money on retrofitting. Compared to wire rings, it can withstand axial loads up to 50 kN, making it ideal for heavy machinery. Many manufacturers prefer it because it complies with ISO 9001 standards and can reduce maintenance costs.

Product details and parameters

Using the bolt secured shaft end retaining ring in your setups makes the whole system more reliable and cuts down on long-term costs. Since you can reuse it, it fits with eco-friendly manufacturing practices. By stopping parts from moving around axially, it reduces noise and vibration, so things run more smoothly. Engineers like that it has a flexible design—you can pair it with seals or spacers for different uses. If you want to improve the performance, safety and cost-effectiveness of your rotating machinery, this retaining ring is a wise choice. And you can be assured that this retaining ring is available worldwide and meets ISO standards.

If you have such a question

Q: What maintenance practices are recommended for bolt secured shaft end retaining ring to prevent failure?

A: To maintain a bolt secured shaft end retaining ring: Check bolt tightness, check the threads aren’t stripped, and look for obvious wear. Use a torque wrench every few months to tighten them again – shaking from use can loosen bolts. When installing, grease the threads to reduce rubbing and prevent damage. In damp or salty areas, use rust-proof spray or pick stainless steel rings. Replace the ring immediately if you spot cracks, bending, or chewed-up threads. Also, make sure the shaft and attached parts line up correctly to avoid uneven pressure. Stick to the maker’s maintenance tips to keep it working safely for longer.