Screw Locking Retaining Ring With Lock Collar

Send Inquiry

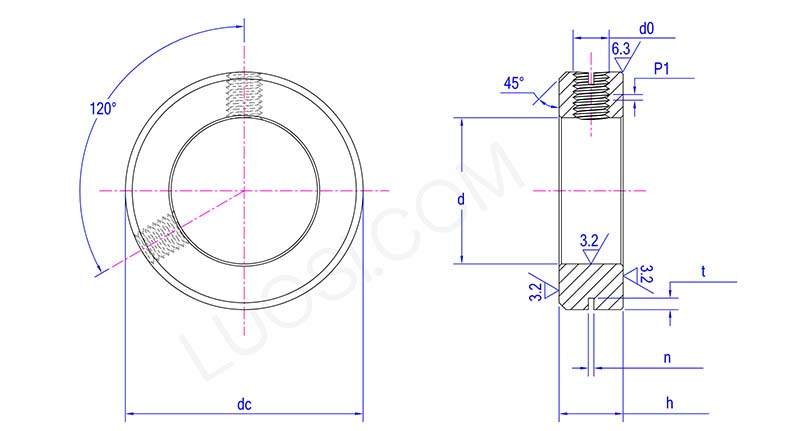

The screw locking retaining ring with lock collar basically keeps bearings, gears, or spinning parts stuck where they should be on shafts or inside housings. It uses a threaded lock collar along with a retaining ring,two pieces working together. Even when things get shaky or there’s pushing/pulling forces, it stops parts from sliding along the shaft. Unlike regular snap rings that just clip into place, this one lets you tweak how tight it sits using screws in the collar. That makes it less likely to fail in rough conditions,think factory equipment, car parts, or airplane components. The two-piece setup is simple to put in (no fancy tools needed) and grips hard enough for jobs where you can’t have stuff wiggling loose over time. Good for applications where you want to set it and forget it.

Advantage

The screw locking retaining ring with lock collar works well because it handles shakes and can be reused multiple times. The threaded collar lets you fine-tune its position along the shaft,that’s why it’s less likely to work loose on its own, unlike regular retaining rings that sometimes pop off. The built-in screws press down evenly across the shaft, so you won’t end up gouging or scratching the surface. It fits both metric and inch-sized parts, which is handy since factories worldwide use mixed measurement systems. You can slap it on or yank it off fast with basic tools like a hex key, meaning less time wasted during repairs or maintenance. For machines that get beaten up daily, this thing’s cheaper to use over time compared to replacing failed standard rings.

Screw locking retaining ring with lock collar feature a threaded locking ring that screws directly onto shafts or bearing housings, providing a secure, vibration-resistant lock. Unlike conventional retaining rings that require bending to secure, these retaining rings use an adjustable screw on the locking ring to apply steady pressure around the shaft. Even under high speeds or high forces, these retaining rings prevent displacement. The locking ring also distributes pressure evenly so that the shaft is not compressed in a single area. The combination of retaining rings and locking rings is suitable for applications that require precise alignment and long-term stability, such as gear systems or factory equipment.

|

Mon |

Φ32 |

Φ35 |

Φ40 |

Φ45 |

Φ50 |

Φ55 |

Φ60 |

Φ65 |

Φ70 |

Φ75 |

Φ80 |

|

d max |

32.062 | 35.062 | 40.062 | 45.062 | 50.062 | 55.074 | 60.074 | 65.074 | 70.074 | 75.074 | 80.074 |

|

d min |

32 | 35 | 40 | 45 | 50 | 55 | 60 | 65 | 70 | 75 | 80 |

|

h max |

14 | 16 | 16 | 18 | 18 | 18 | 20 | 20 | 20 | 22 | 22 |

|

h min |

13.57 | 15.57 | 15.57 | 17.57 | 17.57 | 17.57 | 19.48 | 19.48 | 19.48 | 21.48 | 21.48 |

|

n max |

1.51 | 1.91 | 1.91 | 1.91 |

1.91 |

1.91 |

1.91 |

1.91 |

1.91 |

2.31 | 2.31 |

|

n min |

1.26 | 1.66 |

1.66 |

1.66 |

1.66 |

1.66 |

1.66 |

1.66 |

1.66 |

2.06 | 2.06 |

|

t max |

2.75 | 3.3 |

3.3 |

3.3 |

3.3 |

3.3 |

3.3 |

3.3 |

3.3 |

3.96 | 3.96 |

|

t min |

2.25 | 2.7 |

2.7 |

2.7 |

2.7 |

2.7 |

2.7 |

2.7 |

2.7 |

3.24 | 3.24 |

|

dc |

52 | 56 | 62 | 70 | 80 | 85 | 90 | 95 | 100 | 110 | 115 |

|

d0 |

M8 | M10 |

M10 |

M10 |

M10 |

M10 |

M10 |

M10 |

M10 |

M12 |

M12 |

|

P1 |

1.25 | 1.5 |

1.5 |

1.5 |

1.5 |

1.5 |

1.5 |

1.5 |

1.5 |

1.75 | 1.75 |