Locking Collar with Bolt Fixation

Send Inquiry

For the locking collar with bolt fixation, you can pick materials based on what you need. Carbon steel (like SAE 1070/1095) is used when you need a strong material for tough jobs. Stainless steel (AISI 304/316) works well in places where things might rust or corrode. Titanium alloys are good for aerospace stuff where they need it light but strong. There’s also specialty stuff like Inconel® for situations with extreme temperatures, either really hot or really cold.

They test each material carefully to make sure it holds up—checking how much it can stretch without breaking (up to 1500 MPa) and how much wear it can handle over time. The variety of materials means this retaining ring can work in lots of different environments, from super cold places to high-heat factories.

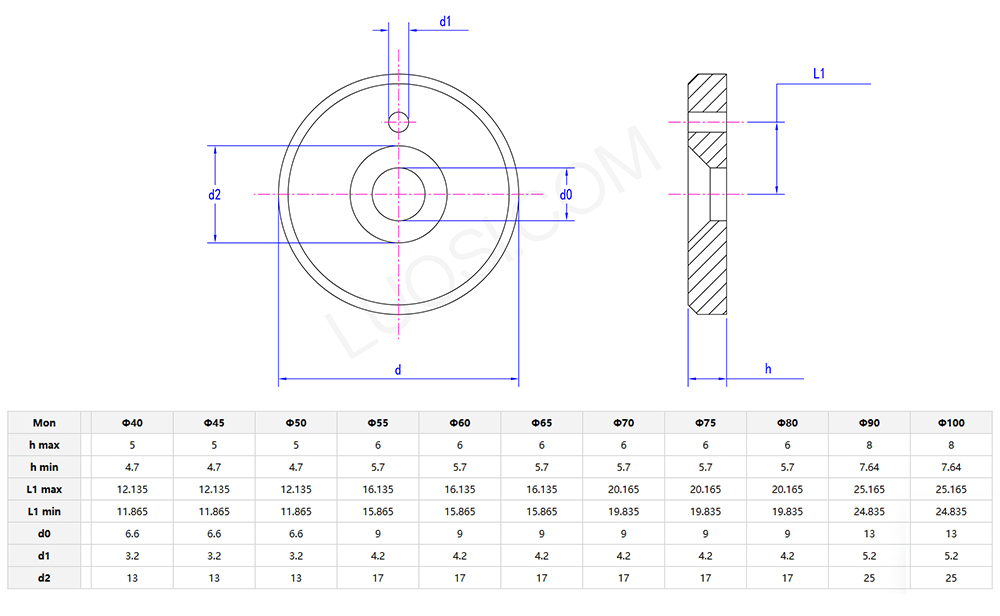

Product details and parameters

Taking care of the locking collar with bolt fixation means doing regular checks on bolt tightness, surface wear, or rust. During maintenance, tighten the bolts to the manufacturer’s recommended torque (usually 20-50 Nm). Use gentle cleaners to wipe off debris and put some anti-seize grease on the threads to make it easier to take apart later. If you see cracks or the ring is misshapen, swap it out. Store the rings in a dry place with controlled temperature to keep them from getting damaged before you install them. Keeping up with this routine helps them work best and can make them last up to 30% longer.

If you have such a question

Q: How do I determine the correct size of a locking collar with bolt fixation for my shaft diameter?

A: Picking the right locking collar with bolt fixation depends on your shaft’s thickness (OD) and thread type. Start by measuring your shaft’s thickness and compare it with the maker’s size guide. Key things to note: the collar’s inner size needs to match the shaft’s threads, the bolt size, and how chunky the collar is. If your shaft isn’t threaded, you’ll need to add threads first. Always double-check if threads are metric or imperial – mixing them up causes headaches. For odd-sized shafts, custom collars exist but they’ll take extra time and money.