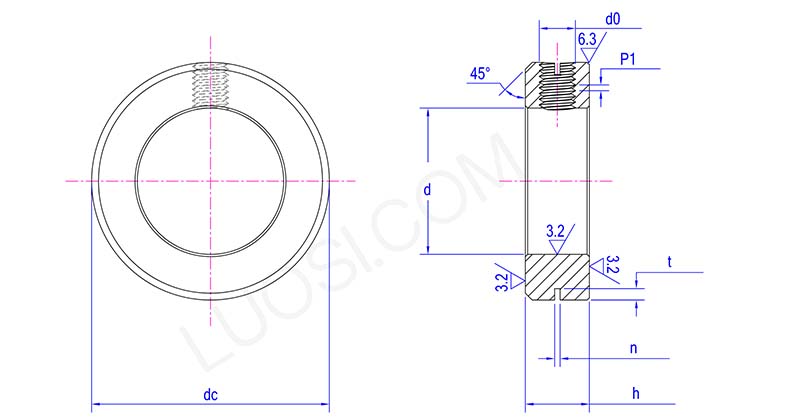

Set Screw Collar

Send Inquiry

Set screw collar is a circular, ring-shaped fastener with a set screw. It's easy to install by one person, requiring no special tools. To remove, simply loosen the lock nut. It's widely used in large electric motors, crushers, mining machinery, CNC machine tools, printing machinery, and other equipment.

Mon

Φ8

Φ9

Φ10

Φ12

Φ13

Φ14

Φ15

Φ16

Φ17

Φ18

Φ19

d max

8.036

9.036

10.036

12.043

13.043

14.043

15.043

16.043

17.043

18.043

19.052

d min

8

9

10

12

13

14

15

16

17

18

19

h max

10

10

10

10

10

12

12

12

12

12

12

h min

9.64

9.64

9.64

9.64

9.64

11.57

11.57

11.57

11.57

11.57

11.57

n max

1.2

1.2

1.2

1.2

1.2

1.2

1.2

1.2

1.2

1.2

1.2

n min

1.06

1.06

1.06

1.06

1.06

1.06

1.06

1.06

1.06

1.06

1.06

t max

1.98

1.98

1.98

1.98

1.98

2.2

2.2

2.2

2.2

2.2

2.2

t min

1.62

1.62

1.62

1.62

1.62

1.8

1.8

1.8

1.8

1.8

1.8

dc

20

22

22

25

25

28

30

30

32

32

35

d0

M5

M5

M5

M5

M5

M6

M6

M6

M6

M6

M6

P1

0.8

0.8

0.8

0.8

0.8

1

1

1

1

1

1

Xiaoguo® make this screw lock ring in different materials based on what you need. For resisting chemicals, we use stainless steel grades like 304 or 316. If it’s going into a high-stress situation, will use alloy steel 4140. And for aerospace stuff where weight matters, there’s lightweight titanium. There are also versions with polymer coatings to cut down on corrosion when you have mixed-metal setups. All the materials go through tough hardness testing (HRC 35-50) and ultrasonic checks to make sure they meet industry standards like ASME B18.27 and DIN 471/472 for how much load they can handle.

Regular inspection and maintenance

To keep the set screw collars working well, check the set screw tightness now and then using a torque wrench,aim for 10-15 Nm. Use a solvent to clean the threads and get rid of any dirt, and put fresh lithium-based grease on them every year. Don’t overtighten the screws, since that can mess up the lock collar. If it’s exposed to seawater or acids, check the coating twice a year to make sure it’s still good. If you see wear deeper than 0.1mm on the parts that touch, you should replace it.

What shaft tolerances are compatible?

The set screw collars works with shaft sizes from 10mm to 200mm, using common tolerance levels like h9 or h11. The adjustable screws on the lock collar can handle small shaft bumps or unevenness (up to ±0.05mm), so it still fits tight without messing up how it works.