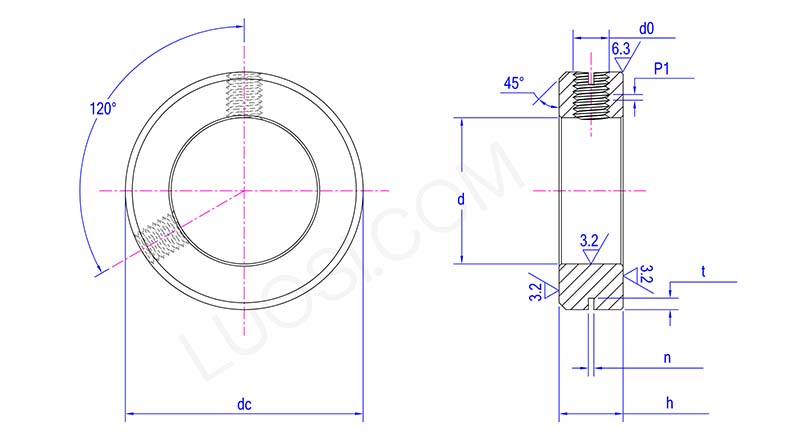

Screw Lock Ring With Set Screw

Send Inquiry

This screw lock ring with set screw doesn’t need the usual grooves that circlips use, so it keeps the shaft strong. It has a two-part locking setup: it uses both radial compression and axial pressure from the screws. That means it can hold 30% more weight than single-part rings. The designs are checked with computer models to make sure stress spreads evenly across the whole part. It’s been tested to handle over 10 million fatigue cycles and works better than others in shock-load situations. It meets standards like MIL-R-5513 and ISO 1234.

Advantages

The modular design of the screw lock ring with set screw allows for adjustment to uneven loads or misaligned installations. By limiting axial displacement to within 0.02 mm, bearing wear and energy loss are reduced. We offer a 5-year warranty and are RoHS/REACH compliant, making them environmentally friendly. We support customization and have years of fastener industry expertise, providing fast delivery and engineering support to ensure your system operates properly.

In Corrosive Environments

The screw lock ring with set screw comes in rust-proof options like 316 stainless steel or zinc-nickel coated carbon steel,these don’t get wrecked by water, chemicals, or salty air. The lock collar’s shape avoids leaving gaps where nasty gunk could pile up and eat at the metal. You can even get screws with that PTFE stuff (you know, like non-stick pan coating) if you need them to last longer. If you’re working on boats or oil rigs, grab the versions with rubbery silicone seals, stops different metals from reacting and corroding each other,these screw lock rings have been tested for over 500 hours with artificial seawater mist spray.

Mon

Φ125

Φ130

Φ135

Φ140

Φ145

Φ150

Φ160

Φ170

Φ180

Φ190

Φ200

d max

125.1

130.1

135.1

140.1

145.1

150.1

160.1

170.1

180.1

190.115

200.115

d min

125

130

135

140

145

150

160

170

180

190

200

h max

30

30

30

30

30

30

30

30

30

30

30

h min

29.48

29.48

29.48

29.48

29.48

29.48

29.48

29.48

29.48

29.48

29.48

n max

2.31

2.31

2.31

2.31

2.31

2.31

2.31

2.31

2.31

2.31

2.31

n min

2.06

2.06

2.06

2.06

2.06

2.06

2.06

2.06

2.06

2.06

2.06

t max

4.95

4.95

4.95

4.95

4.95

4.95

4.95

4.95

4.95

4.95

4.95

t min

4.05

4.05

4.05

4.05

4.05

4.05

4.05

4.05

4.05

4.05

4.05

dc

165

170

175

180

190

200

210

220

230

240

250

d0

M12

M12

M12

M12

M12

M12

M12

M12

M12

M12

M12

P1

1.75

1.75

1.75

1.75

1.75

1.75

1.75

1.75

1.75

1.75

1.75