China Structural Washers Manufacturer, Supplier, Factory

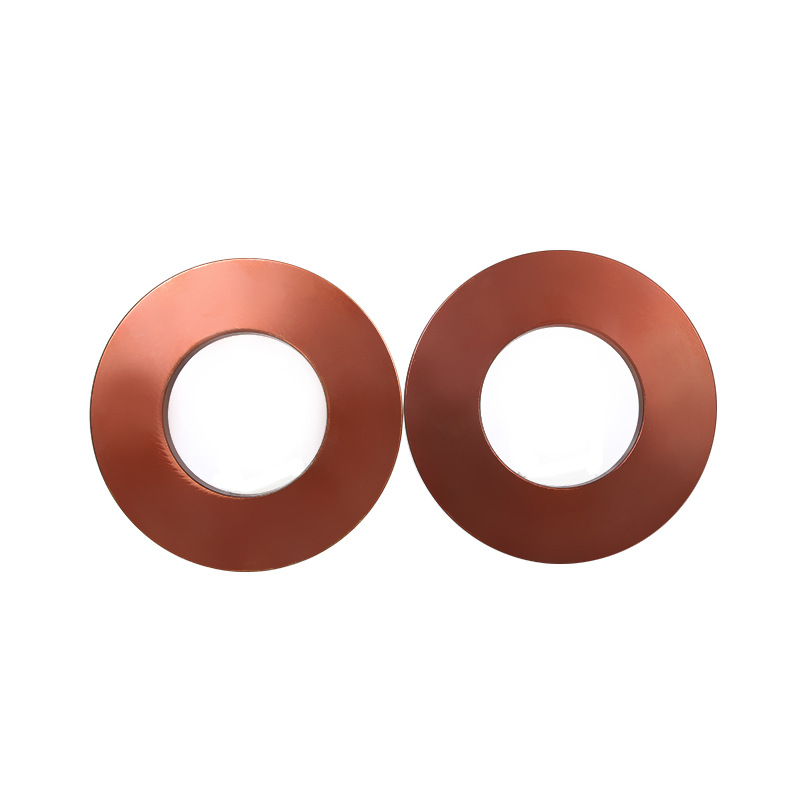

When it comes to industrial and construction applications, the importance of reliable fastening components cannot be overstated. Among these, Washers play a critical role in distributing load, preventing loosening, and protecting surfaces from damage. Specifically, Structural Washers are engineered to meet rigorous standards in heavy-duty scenarios, such as structural steel connections, machinery assembly, and infrastructure projects. These specialized Washers are designed to handle high tensile and shear forces, ensuring long-term stability and safety. Whether you're working on bridges, buildings, or heavy equipment, selecting the right type of Washers is essential for maintaining structural integrity and performance.

Structural Washers are manufactured with precision to comply with international standards, such as ASTM F436 and SAE J429. These washers undergo stringent quality checks to guarantee uniformity and durability. The primary function of Structural Washers is to provide a large bearing surface, which helps in reducing stress concentration and preventing bolt or nut embedding into the connected material. Made from high-strength materials, Structural Washers resist deformation under extreme loads and harsh environmental conditions. They are commonly used in conjunction with high-strength bolts in critical joints, where failure is not an option. By ensuring proper load distribution, Structural Washers contribute significantly to the overall safety and longevity of the structure.

- Material: High-carbon steel, stainless steel, or galvanized steel

- Hardness: Rockwell C scale 26-32 for carbon steel washers

- Finish: Plain, hot-dip galvanized, or mechanical zinc plating

- Standards: ASTM F436, SAE J429, ISO 7411

- Temperature Range: -40°F to 400°F (-40°C to 204°C)

- Corrosion Resistance: Varies by material and coating; galvanized washers offer enhanced protection

| Size (Nominal Bolt Diameter) | Outside Diameter (OD, inches) | Inside Diameter (ID, inches) | Thickness (inches) | Load Capacity (lbs) |

|---|---|---|---|---|

| 1/2" | 1.25 | 0.562 | 0.134 | 4,200 |

| 5/8" | 1.50 | 0.688 | 0.148 | 6,800 |

| 3/4" | 1.875 | 0.812 | 0.165 | 10,200 |

| 7/8" | 2.125 | 0.938 | 0.188 | 14,500 |

| 1" | 2.50 | 1.062 | 0.210 | 19,000 |

Hot Products

120º Small Countersunk Head Riveted Nuts

Xiaoguo® is a leading China 120º Small Countersunk Head Riveted Nuts manufacturer, supplier and exporter. Adhering to the pursuit of perfect quality of products, so that our 120ºSmall countersunk head riveted nuts have been satisfied by many customers. Extreme design, quality raw materials, high performance and competitive price are what every customer wants, and that's also what we can offer you. Of course, also essential is our perfect after-sales service. If you are interested in our 120ºSmall countersunk head riveted nuts, you can consult us now, we will reply to you in time!Hardened stainless steel hexagonal rivet nut column

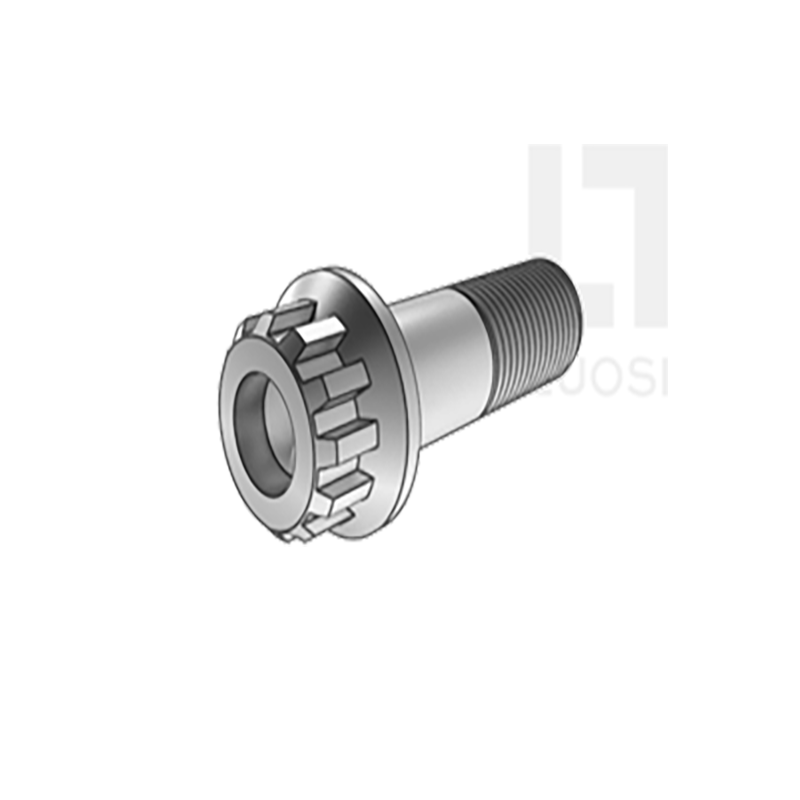

Hardened stainless steel hexagonal rivet nut columns have a flat head and a flat hexagonal shape to increase the contact area and provide stable support. They are commonly used in automotive assembly, metal processing and electronic housings.Xiaoguo® factory has a stable logistics partner that can ship goods quickly and deliver them on time.12 Teeth Spline Bolts With Flange

12 teeth spline bolts with flange are often suitable for projects that require firm and anti-slip connections. It can provide better torque and prevent bolts from slipping during the tightening process. The bolts produced by Xiaoguo® factory comply with the execution standard of MS 14157B-1978.Time Saving Hexagon Weld Nut

The Time Saving Hexagon Weld Nut is a specialized fastener designed for creating a permanent and secure threaded connection by welding onto metal surfaces. What sets Xiaoguo® apart is its commitment to precision, a quality that makes it stand out among manufacturers, ensuring every fastener meets international standards like ISO and DIN.Single Chamfered Square Nuts

Single chamfered square nuts are square in shape, with a chamfer on one end and standard coarse or fine thread threads. Xiaoguo® manufactures fasteners that meet quality standards at affordable prices.Type B Knurled Nuts

The high - quality type B knurled nuts are manufactured by Xiaoguo® Fasteners.The knurled surface makes it easier for workers to tighten manually and grip firmly.