Time Saving Hexagon Weld Nut

Send Inquiry

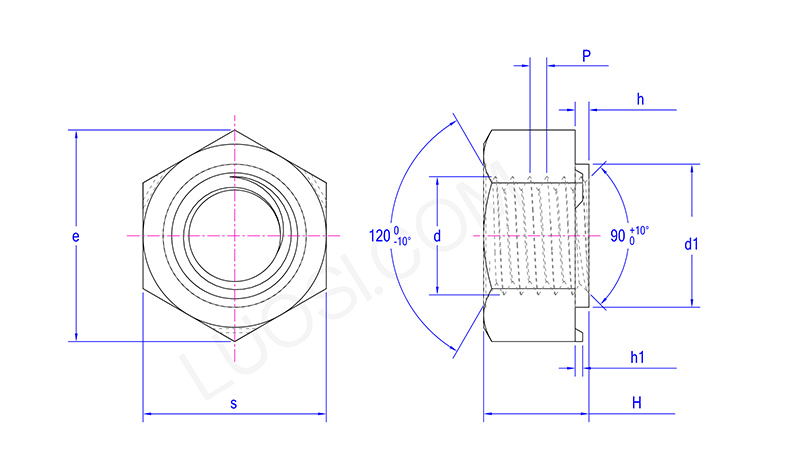

A Time Saving Hexagon Weld Nut is basically a fastener you weld onto metal. It gives you a solid threaded spot that won’t budge. The hex shape makes it easier to hold and line up, so it stays put during welding. Inside, the threads are made cleanly so bolts screw in snug. That’s why it’s handy for all kinds of jobs.

Product Details

The advantage of the Time Saving Hexagon Weld Nut that saves time is that they perform well under heavy loads - they are not prone to breaking, so they are very suitable for heavy-duty work. They can also maintain a tight state under vibration and impact.

This is why this type of design is so common in mechanical components or structural members that are subject to enormous pressure. Its specific shape design and welded node structure can effectively help form a strong and uniform connection during the welding process, thereby ensuring the pressure-bearing stability of the entire structure.

| Mon | M4 | M5 | M6 | M8 | M10 | M12 | M14 | M16 |

| P | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 |

| e min | 9.83 | 10.95 | 12.02 | 15.38 | 18.74 | 20.91 | 24.27 | 26.51 |

| d1 max | 5.97 | 6.96 | 7.96 | 10.45 | 12.45 | 14.75 | 16.75 | 18.735 |

| d1 min | 5.885 | 6.87 | 7.87 | 10.34 | 12.34 | 14.64 | 16.64 | 18.605 |

| h max | 0.65 | 0.7 | 0.75 | 0.9 | 1.15 | 1.4 | 1.8 | 1.8 |

| h min | 0.55 | 0.6 | 0.6 | 0.75 | 0.95 | 1.2 | 1.6 | 1.6 |

| h1 max | 0.35 | 0.4 | 0.4 | 0.5 | 0.65 | 0.8 | 1 | 1 |

| h1 min | 0.25 | 0.3 | 0.3 | 0.35 | 0.5 | 0.6 | 0.8 | 0.8 |

| s max | 9 | 10 | 11 | 14 | 17 | 19 | 22 | 24 |

| s min | 8.78 | 9.78 | 10.73 | 13.73 | 16.73 | 18.67 | 21.67 | 23.67 |

| H max | 3.5 | 4 | 5 | 6.5 | 8 | 10 | 11 | 13 |

| H min | 3.2 | 3.7 | 4.7 | 6.14 | 7.64 | 9.64 | 10.3 | 12.3 |

Q:What materials are your Time Saving Hexagon Weld Nuts made of?

A:Our hex weld nuts are usually made from low carbon steel—they’re easy to weld and handle everyday jobs just fine. If you need more rust protection, we offer stainless steel options like 304 and 316. These all follow standard specs, so whether you're working on regular construction or something around saltwater or chemicals, there’s a type that fits. Basically, you choose based on what’s more important: strength, weldability, or holding up in wet conditions.