12 Teeth Spline Bolts With Flange

Send Inquiry

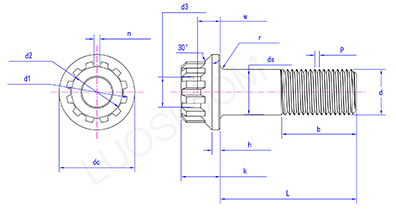

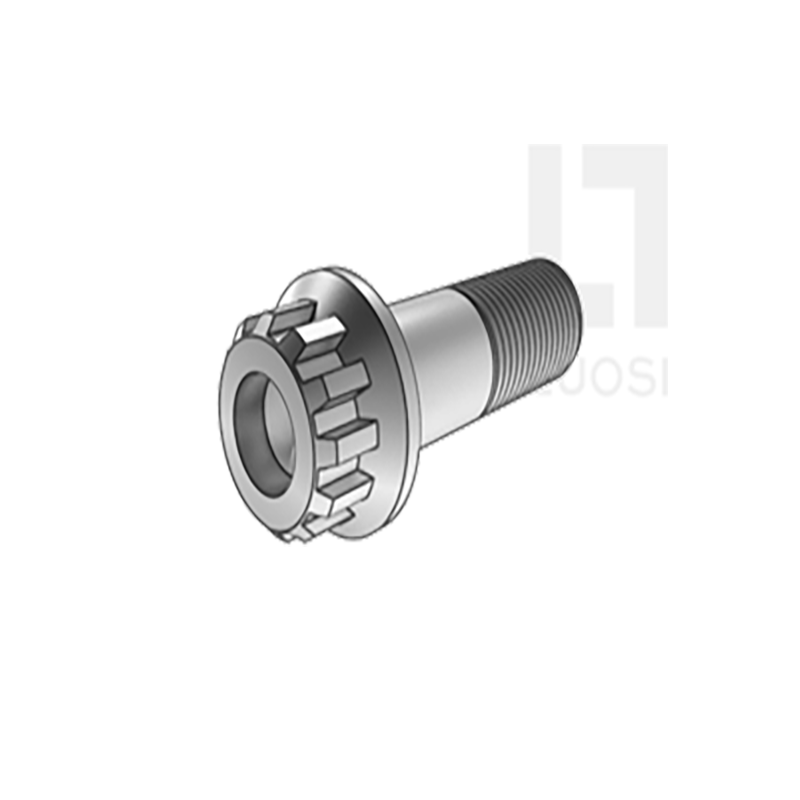

The head of the 12 teeth spline bolts with flange is designed with 12 teeth, which can fit closely with the matching spline socket wrench. At its bottom, there is a flange like a gasket, which can increase the contact area with the connected material.

Product Features

The 12 teeth spline bolts with flange feature a unique structure of 12 teeth spline plus flange. The 12-tooth spline provides more force application points, making the tightening operation more precise and smooth. Flanges disperse pressure, enhance connection stability and prevent bolts from loosening.

These bolts can be connected to the root of the wind turbine blade. The blade bolt is subjected to a centrifugal force of 20 tons. It can bear loads. The spline head can withstand a hydraulic torque of 1,000 N·m. The flange can prevent the root of the composite material from cracking due to micro-movement. It needs to be replaced every five years, and each damaged blade costs as much as 250,000 US dollars.

The 12 teeth spline bolts require matching spline screwdrivers. They can transmit huge torque without stripping, far superior to hexagonal bolts. The built-in flange functions similarly to a gasket, so you can save on additional components. It is highly suitable for the maintenance of heavy equipment.

12 teeth spline bolts with flange are not easy to be tampered with. Most people do not have spline tools. Flanges can keep bolts fixed under vibration and they are used on public machinery or railway tracks where there is a risk of theft. For high-vibration areas (compressors, generators), they can be firmly fixed. The spline driver will not come out. The serrated flange option can bite the surface. No locking washer is required.

Product parameters

| Mon | 1/4 | 5/16 | 3/8 | 7/16 | 1/2 | 9/16 | 5/8 | 3/4 | 7/8 |

| P | 28 | 24 | 24 | 20 | 20 | 18 | 18 | 16 | 14 |

| dc max | 0.438 | 0.531 | 0.649 | 0.75 | 0.828 | 0.938 | 1.05 | 1.23 | 1.438 |

| dc min | 0.428 | 0.521 | 0.639 | 0.74 | 0.818 | 0.928 | 1.04 | 1.22 | 1.428 |

| k max | 0.26 | 0.322 | 0.347 | 0.403 | 0.46 | 0.515 | 0.572 | 0.61 | 0.71 |

| k min | 0.25 | 0.312 | 0.337 | 0.393 | 0.45 | 0.505 | 0.562 | 0.6 | 0.7 |

| h max | 0.055 | 0.071 | 0.079 | 0.092 | 0.112 | 0.122 | 0.133 | 0.165 | 0.19 |

| h min | 0.035 | 0.051 | 0.059 | 0.072 | 0.092 | 0.102 | 0.113 | 0.145 | 0.17 |

| b min | 0.55 | 0.638 | 0.708 | 0.803 | 0.878 | 0.97 | 1.04 | 1.201 | 1.367 |

| d3 max | 0.19 | 0.225 | 0.27 | 0.33 | 0.39 | 0.45 | 0.51 | 0.58 | 0.66 |

| d3 min | 0.15 | 0.185 | 0.23 | 0.29 | 0.35 | 0.41 | 0.47 | 0.54 | 0.62 |

| w min | 0.135 | 0.162 | 0.197 | 0.228 | 0.254 | 0.289 | 0.327 | 0.38 | 0.438 |

| ds max | 0.2495 | 0.312 | 0.3745 | 0.473 | 0.4995 | 0.5615 | 0.624 | 0.749 | 0.874 |

| ds min | 0.2485 | 0.311 | 0.3735 |

0.436 |

0.4985 | 0.5605 | 0.623 | 0.748 | 0.873 |

| d1 max | 0.381 | 0.456 | 0.531 | 0.679 | 0.753 | 0.828 | 0.901 | 1.124 | 1.27 |

| d1 min | 0.373 | 0.447 | 0.522 | 0.668 | 0.742 | 0.817 | 0.89 | 1.112 | 1.258 |

| d2 max | 0.324 | 0.389 | 0.455 | 0.585 | 0.651 | 0.717 | 0.782 | 0.978 | 1.107 |

| d2 min | 0.318 | 0.383 | 0.448 | 0.578 | 0.644 | 0.711 | 0.774 | 0.97 | 1.099 |

| n max | 0.037 | 0.043 | 0.05 | 0.061 | 0.068 | 0.073 | 0.079 | 0.097 | 0.108 |

| n min | 0.031 | 0.037 | 0.043 | 0.054 | 0.06 | 0.065 | 0.071 | 0.088 | 0.099 |

| r max | 0.041 | 0.041 | 0.057 | 0.057 | 0.057 | 0.057 | 0.073 | 0.073 | 0.073 |

| r min | 0.031 | 0.031 | 0.047 | 0.047 | 0.047 | 0.047 | 0.063 | 0.063 | 0.063 |