Force Dense Disc Shaped Spring

Send Inquiry

The aerospace industry has a significant demand for high-performance Force Dense Disc Shaped Spring, such as those used in actuator systems and rotor parts, for critical applications. The reliability of these components is unquestionable, as they must function properly.

To withstand the rigors of extreme temperatures, most springs are made from advanced alloys like Inconel to ensure excellent performance in hot or cold environments. The components are of high quality and the prices are very competitive. If you place an order for more than 2,000 units, you will receive a 10% discount. Usually, we provide a naturally passivated surface for them.

In terms of transportation, we collaborate with professional logistics partners to ensure they can be delivered quickly and safely. Each disc spring is traceable and comes with material certification. They also comply with the AS9100 standard.

Product Details

In oil and gas operations, blowout preventers and wellhead equipment use Force Dense Disc Shaped Spring. They ensure that the sealing force remains stable under high-pressure conditions.

To achieve the appropriate spring stiffness and deformation, these components are usually made by stacking multiple discs. We offer competitive prices for the energy industry. We implement a tiered pricing system. The higher the order amount, the greater the discount you will enjoy. The common anti-corrosion coating for them is yellow zinc chromate.

We have established long-term cooperation with reliable freight forwarders to ensure that spring products can be delivered on time and the delivery range can cover remote areas. The packaging is waterproof and not prone to being crushed. Additionally, each spring undergoes strict pre-loading and pressure testing before shipment.

|

Disc-shaped spring standard version |

|||||||||

|

|

Geometric parameters |

Mechanical properties |

Weight |

||||||

|

f=0.50h f=0.75h |

|||||||||

|

|

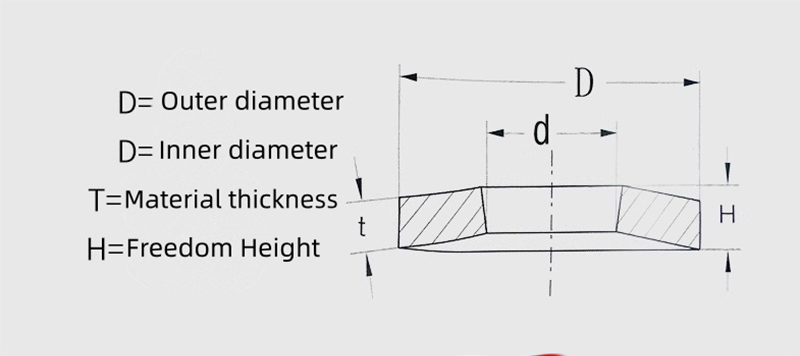

D |

d |

t |

h/t |

F |

P |

F |

P |

kg/100 |

|

C |

8.0 |

4.2 |

0.20 |

0.45 |

0.125 |

33 |

0.188 |

39 |

0.06 |

|

B |

8.0 |

4.2 |

0.30 |

0.55 |

0.125 |

89 |

0.188 |

118 |

0.09 |

|

A |

8.0 |

4.2 |

0.40 |

0.65 |

0.100 |

147 |

0.150 |

210 |

0.11 |

|

C |

10.0 |

5.2 |

0.25 |

0.55 |

0.150 |

48 |

0.225 |

58 |

0.11 |

|

B |

10.0 |

5.2 |

0.40 |

0.70 |

0.150 |

155 |

0.225 |

209 |

0.18 |

|

A |

10.0 |

5.2 |

0.50 |

0.75 |

0.125 |

228 |

0.188 |

325 |

0.22 |

|

D |

12.0 |

6.2 |

0.60 |

0.95 |

0.175 |

394 |

0.262 |

552 |

0.39 |

|

C |

12.5 |

6.2 |

0.35 |

0.80 |

0.225 |

130 |

0.338 |

151 |

0.25 |

|

B |

12.5 |

6.2 |

0.50 |

0.85 |

0.175 |

215 |

0.262 |

293 |

0.36 |

|

A |

12.5 |

6.2 |

0.70 |

1.00 |

0.150 |

457 |

0.225 |

660 |

0.51 |

|

C |

14.0 |

7.2 |

0.35 |

0.80 |

0.225 |

106 |

0.338 |

123 |

0.31 |

|

B |

14.0 |

7.2 |

0.50 |

0.90 |

0.200 |

210 |

0.300 |

279 |

0.44 |

|

A |

14.0 |

7.2 |

0.80 |

1.10 |

0.150 |

547 |

0.225 |

797 |

0.71 |

|

C |

16.0 |

8.2 |

0.40 |

0.90 |

0.250 |

131 |

0.375 |

154 |

0.47 |

|

B |

16.0 |

8.2 |

0.60 |

1.05 |

0.225 |

304 |

0.388 |

410 |

0.70 |

|

A |

16.0 |

8.2 |

0.90 |

1.25 |

0.175 |

697 |

0.262 |

1013 |

1.05 |

|

C |

18.0 |

9.2 |

0.45 |

1.05 |

0.300 |

185 |

0.450 |

214 |

0.68 |

|

B |

18.0 |

9.2 |

0.70 |

1.20 |

0.250 |

417 |

0.375 |

566 |

1.03 |

|

A |

18.0 |

9.2 |

1.00 |

1.40 |

0.200 |

865 |

0.300 |

1254 |

1.48 |

FAQ

Q:How do you ensure the quality and consistency of your spring?

A:Every batch of our Force Dense Disc Shaped Spring undergoes rigorous testing, including load-deflection checks, dimensional verification, and salt spray tests. We adhere to strict quality control protocols, ensuring every spring meets international standards like DIN 2093 for consistent performance.