China Spring Washer Manufacturer, Supplier, Factory

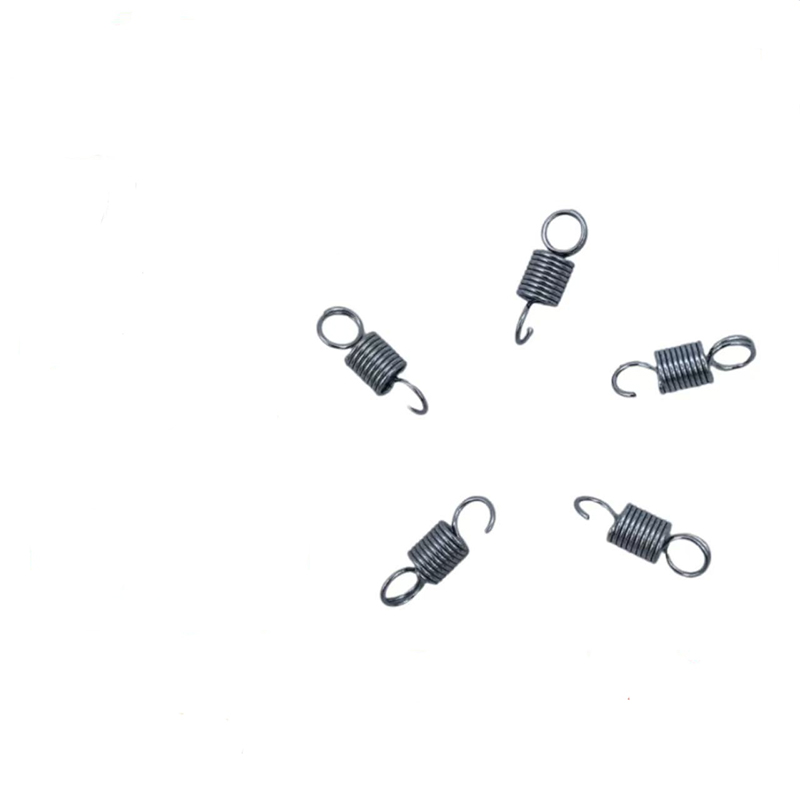

What is a Spring Washer?

A spring washer, also known as a disc spring or Belleville washer, is a type of fastener designed to provide a flexible preload and maintain tension in bolted assemblies. These conical-shaped washers compress under load, acting like a spring to absorb shock, reduce vibration, and prevent loosening due to thermal expansion or dynamic forces. They are crucial components in countless mechanical systems, from automotive and aerospace to heavy machinery and consumer electronics, ensuring the long-term reliability and safety of fastened joints.

Key Features and Benefits of Our Spring Washers

- Superior Vibration Dampening: Our washers are engineered to absorb and dissipate vibrational energy, effectively preventing nuts and bolts from loosening over time.

- Constant Tension Maintenance: The spring action maintains a consistent clamp force, compensating for material settling, gasket creep, or thermal cycling.

- High Load Capacity: Despite their compact size, our spring washers can support significant static and dynamic loads.

- Corrosion Resistance: Available in various materials and coatings to withstand harsh environmental conditions.

- Reusability: Manufactured from high-grade materials that allow for multiple uses without significant loss of spring properties.

Detailed Product Specifications

Our spring washers are manufactured to international standards, including DIN 6796 and ANSI B18.21.1, ensuring consistent quality and performance. Below is a detailed breakdown of our product specifications.

Standard Material and Coating Options

| Material Grade | Standard | Typical Hardness (HRC) | Common Coatings | Temperature Range |

|---|---|---|---|---|

| Carbon Steel (C75) | DIN 17222 | 42 - 50 | Zinc Plated, Phosphate | -20°C to +120°C |

| Stainless Steel (AISI 302/304) | DIN 17224 | 38 - 45 | Passivated | -200°C to +250°C |

| Stainless Steel (AISI 316) | DIN 17224 | 36 - 42 | Passivated | -200°C to +250°C |

| Inconel 718 | AMS 5596 | 36 - 44 | None (High-Temp Alloy) | -250°C to +650°C |

Standard Size Chart (Based on DIN 6796)

| Nominal Size (d1 - mm) | Washer Diameter (D - mm) | Washer Height (H - mm) | Approx. Load at 75% Deflection (N) |

|---|---|---|---|

| M3 | 6.0 | 0.6 | 310 |

| M4 | 8.0 | 0.8 | 510 |

| M5 | 9.0 | 1.0 | 830 |

| M6 | 11.5 | 1.2 | 1100 |

| M8 | 15.0 | 1.6 | 2100 |

| M10 | 18.0 | 2.0 | 3400 |

| M12 | 22.0 | 2.5 | 5000 |

| M16 | 28.0 | 3.0 | 9200 |

Applications and Industries

Spring washers are versatile components used to solve fastening challenges across a wide spectrum of industries. Their primary function is to prevent self-loosening of fasteners subjected to vibration and thermal fluctuations.

- Automotive: Engine mounts, transmission systems, suspension components, and brake assemblies.

- Aerospace: Critical airframe structures, engine components, and avionics systems where reliability is paramount.

- Heavy Machinery: Construction equipment, agricultural machinery, and industrial presses.

- Electronics: Securing components on PCBs and within enclosures that are subject to shock or vibration.

- Energy Sector: Wind turbines, oil and gas drilling equipment, and power generation systems.

Technical Design Considerations

When selecting a spring washer for your application, several key factors must be considered to ensure optimal performance and longevity. The load-deflection characteristics are critical. A single washer provides a specific spring rate, but stacking them in parallel increases the load capacity, while stacking in series increases deflection. It is vital to calculate the required preload and the working deflection range to prevent the washer from being flattened ("bottoming out"), which would nullify its spring function. Proper surface finish and flatness of the mating surfaces are also essential to ensure uniform load distribution and prevent premature failure. For highly corrosive environments, material selection becomes the primary concern, often necessitating stainless steel or specialized alloys like Inconel.

Hot Products

NU Nylon Insert Lock Nut

Check Xiaoguo®’s Price list for NU nylon insert lock nut or request a quick quote. No fluff-just reliable nuts at low cost. Used by factories worldwide.Slotted Pan Head Screws And Plain Washer Assemblies

Baoding Xiaoguo Intelligent Equipment Co., LTD. was set up formally in 2012, as one of the professional Slotted pan head screws and plain washer assemblies manufacturer and China Slotted pan head screws and plain washer assemblies factory, we are strong strength and complete management. Also, we have own exporting license. We mainly deal in making a series of Slotted pan head screws and plain washer assemblies and so on. We stick to the principal of quality orientation and customer priority, we sincerely welcome your letters, calls and investigations for business cooperation. We assure you of our high quality services at all time.Small Hexagon Head Bolts

Small hexagon head bolts have a smaller diameter and are used to connect and fix various mechanical equipment parts.Xiaoguo® can customize according to the drawings you provide. If you don't have the product drawings, you can provide us with the size, model, material, surface treatment, application and quantity of the product.20°Clipped Head Plow Bolts

The 20°Clipped head plow bolts produced by Xiaoguo® factory are in accordance with the ASME/ANSI B18.9-5-2012 standard. Our bolts are sturdy and durable, and have undergone strict quality control. We offer 24-hour online service. You can contact us at any time to inquire about prices.Precision Stamped Square Washer

Precision stamped square washer, which is favored by many manufacturers, provides greater surface area and resistance to rotation during tightening compared to a round washer. Customers choose Xiaoguo® for its competitive pricing and consistent product excellence.Slotted For Control Crown Nut With Slot

Slotted For Control Crown Nut With Slot has its primary function of being used in conjunction with a cotter pin to prevent the nut from loosening under vibration. A robust ERP system allows Xiaoguo®—acting as the supplier—to manage complex orders and provide real-time updates to customers.