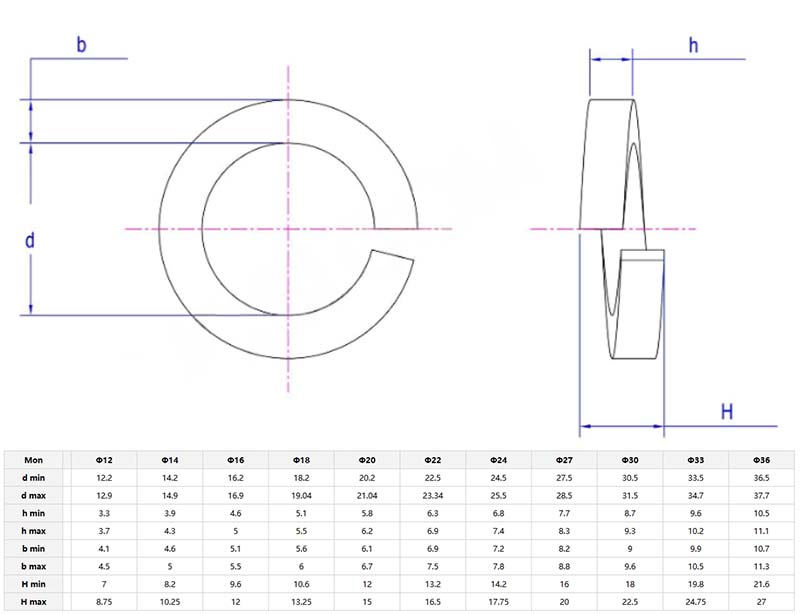

Heavy Duty Spring Washer

Send Inquiry

Heavy duty spring washers are made from durable materials, common materials include carbon steel (for high strength), stainless steel (such as A2/A4 grade) to resist rust, and phosphor bronze for electrical applications where conductivity is required. Heating the material during the manufacturing process (heat treating) helps increase the ability to withstand repeated stresses without wearing out. Some spring washers contain zinc or nickel plating in their material to resist water, chemicals, or weather.

Material Choose

Material choice for heavy duty spring washers affects three main things: how much weight they can take, their temperature limits, and how long they’ll last. For instance, aerospace uses Inconel spring washers because they handle extreme heat. Using the same material across all washers ensures they flex consistently under pressure,this matters for keeping bolts securely tightened in demanding, precision-heavy situations like machinery or industrial equipment.

Application

Heavy duty spring washers are really important in systems that shake a lot, like car suspensions, HVAC units, and industrial pumps. They keep bolts tight in places with high torque, such as wind turbines and robotics, which stops joints from breaking. In electrical setups, they use non-conductive spring washers to keep the ground connection steady.

In construction, heavy duty spring washers help structural bolts stay stable during earthquakes. They’re also used in consumer electronics,smaller versions stop screws from loosening in devices. Whether it’s marine equipment that needs to resist saltwater rust or aerospace parts that have to handle extreme pressures, spring washers work reliably in many different industries.

High-vibration Applications

Q: Can heavy duty spring washers maintain tension in high-vibration applications better than alternatives like thread lockers?

A: Heavy duty spring washers work better in high-vibration environments than alternatives such as threadlockers because they continuously apply axial force to prevent the fastener from loosening, whereas threadlockers can lose effectiveness over time. The helical shape of the spring washer absorbs shock forces and maintains a steady clamping force even in situations of constant motion, such as in cars or industrial machinery.

But if the vibrations are really extreme, using spring washers with thread-locking glue adds an extra layer of security. While you have to reapply thread lockers during maintenance, spring washers can be used again and don’t need much upkeep. Always test how they work together in your specific setup to make sure everything stays reliable.