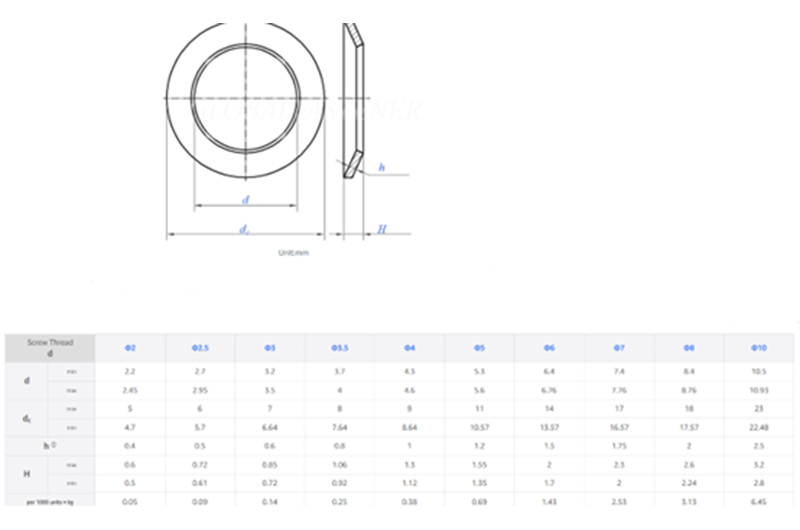

Conical Spring Washer

Send Inquiry

Conical spring washers are elastic to increase the full elasticity of the connection pair. The inherent elasticity can compensate for the loss of preload force to meet the clamping force requirements, making the connection more secure.

Features

Conical spring washer with positive locking serrations are highly resistant to vibration and loosening;

Concentric force transmission and uniform axial loads eliminate bending moments in the bolt and prevent deformation.

Locking serrations prevent friction and protect components from damage.

Closed-loop design with high tension force, no bursting problems.

Advantages

Conical spring washer utilizes a closed-loop design that produces high tension while avoiding the bursting problems that can occur with conventional washers.

Conical spring washer prevents bolt deformation from the root cause, extends bolt life and reduces maintenance costs.

Working principle

The working principle of Conical Spring Washer is in the bolt, nut connection assembly, by the axial load, deformation storage of axial tension potential energy, when the nut or bolt loosening, the washer rebound to release the potential energy to play a role in preventing the loosening of DIN6796 design principle is to eliminate the bolt and nut in the assembly of the undesirable effects of the loosening of, and thus play a role in locking.