Shaft End Clamp Collar with Bolts

Send Inquiry

Shaft end clamp collar with bolts often get surface treatments to boost durability. For example: zinc coating stops rust, black oxide reduces rubbing damage, and phosphate layers help parts slide smoothly. Electroless nickel works better around harsh chemicals, and powder coating adds thicker protection (while looking cleaner). These coatings don’t just prevent rust or wear – they also make the collar less likely to get stuck when installing or removing it, especially in dirty or wet places.

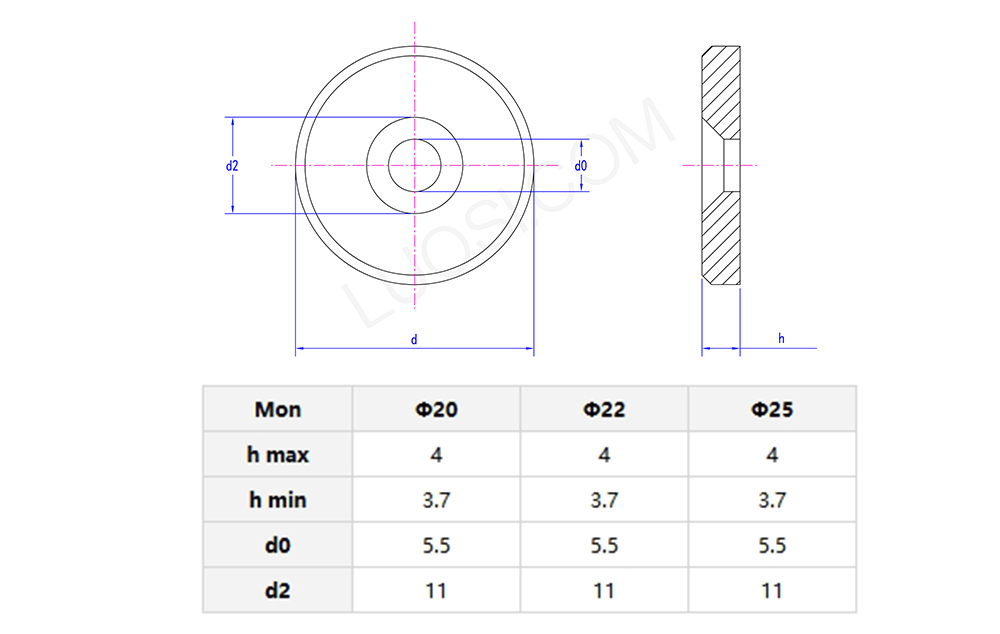

Product details and parameters

The shaft end clamp collar with bolts comes in standard sizes and can also be made to order, fitting shaft diameters from 10mm up to 300mm. Important measurements include the inner and outer diameter, bolt thread size (like M4 to M12), and the ring’s thickness (2mm to 15mm). You can adjust the bolt patterns and torque requirements to match specific assembly needs. There are CAD drawings and tolerance charts available (with a precision of around ±0.05mm) to make sure it fits well. This type of fastener is suitable for both small machines and large industrial installations.

If you have such a question

Q: Can the shaft end clamp collar with bolts accommodate high-speed or heavy-load applications?

A: Yeah, the shaft end clamp collar with bolts is made for tough jobs, like when things are spinning fast or there’s a lot of axial load. The threaded design spreads out the stress across the shaft, so it doesn’t wear down one area too much. If you’re dealing with extreme conditions, go for rings that have stronger bolt setups or surfaces that are heat-treated to be harder. You need to ensure that the material and thread of the shaft are strong enough to withstand the pressure from the shaft ring. If it is used in a place with frequent activities, it is best to check whether the bolts are loose and whether the threads are worn out from time to time. In places with severe vibration, you can apply thread locking glue (such as anti-loosening glue) to make the shaft more stable.