Robustly Constructed Steel Wire Rope

Send Inquiry

Robustly Constructed Steel Wire Rope are indispensable materials in the marine and offshore operation industries. They are used as mooring lines, towing lines and anchor cables for ships and oil drilling platforms.

They have a good strength-to-weight ratio and can withstand dynamic loads, thus performing well in these harsh environments. The Robustly-Constructed Steel Wire Ropes used here are usually treated with galvanization or coated with zinc-aluminum alloy coatings. This coating gives them a strong ability to resist saltwater corrosion - thus they can be safely used and have a longer service life even in the most demanding environments for steel products.

Product Benefits

In the construction industry, Robustly Constructed Steel Wire Rope are like the "backbone" of cranes, lifting systems and suspension bridges - without them, nothing can be done.

It has sufficient tensile strength to lift and move heavy objects, such as structural steel, concrete slabs and prefabricated components. The reliability of this type of Robustly-Constructed Steel Wire Rope is of crucial importance here - as it directly affects the safety of the construction site.

With its dual characteristics of good flexibility and extremely strong strength, this product can achieve stable and smooth operation on the surface of pulleys and rollers. This is also the core reason why it has become a vital basic component in modern architecture and remains irreplaceable.

Product Parameters

|

Specification Of Stainless Steel Wire Rope |

||||

|

|

||||

|

Product structure |

Specification(mm) |

Tension(kn) |

Load-bearing(kg) |

Reference weight(kg/100m) |

|

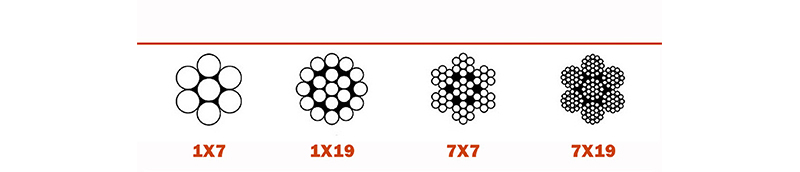

1x7 |

2 | 4.11 | 440 | 2.2 |

| 2.5 | 6.76 | 690 | 3.4 | |

| 3 | 9.81 | 1000 | 4.9 | |

| 3.5 | 13.33 | 1360 | 6.8 | |

| 4 | 17.46 | 1780 | 8.8 | |

|

|

||||

|

Product structure |

Specification(mm) |

Tension(kn) |

Load-bearing(kg) |

Reference weight(kg/100m) |

|

1x19 |

4 | 17.46 | 1780 | 9.1 |

| 5 | 25.49 | 2600 | 14.2 | |

| 6 | 35.29 | 3600 | 20.5 | |

| 7 | 49.02 | 5000 | 27.9 | |

| 8 | 61.76 | 6300 | 36.5 | |

| 10 | 98.04 | 10000 | 57 | |

| 12 | 143.15 | 14500 | 82.1 | |

|

|

||||

|

Product structure |

Specification(mm) |

Tension(kn) |

Load-bearing(kg) |

Reference weight(kg/100m) |

|

7x7 |

1 | 0.56 | 57 | 0.38 |

| 1.2 | 1.13 | 115 | 0.5 | |

| 1.5 | 1.26 | 128 | 0.86 | |

| 1.8 | 1.82 | 186 | 1.3 | |

| 2 | 2.24 | 228 | 1.54 | |

| 2.5 | 3.49 | 356 | 2.4 | |

| 3 | 5.03 | 513 | 3.46 | |

| 4 | 8.94 | 912 | 6.14 | |

|

|

|

|||

|

Product structure |

Specification(mm) |

Tension(kn) |

Load-bearing(kg) |

Reference weight(kg/100m) |

|

7x19 |

5 | 13 | 1330 | 9.3 |

| 6 | 18.8 | 1920 | 13.4 | |

| 7 | 25.5 | 2600 | 18.2 | |

| 8 | 33.4 | 3410 | 23.8 | |

| 10 | 52.1 | 5310 | 37.2 | |

| 12 | 85.1 | 7660 | 53.6 | |

The above table represents the standard specifications. There are numerous inventory specifications available. For specific requirements, please contact the customer service for inquiries.

Main Materials

Our Robustly Constructed Steel Wire Rope is mostly made from high-carbon steel or stainless steel.

High carbon steel has high strength and good wear resistance, and can handle the load and wear in tough work. It is suitable for use as lifting components or various types of rigging. Stainless steel (common grades such as 304 or 316) has excellent corrosion resistance and can well withstand marine atmosphere, chemical corrosion and outdoor wind and rain erosion, making it an ideal material for the above harsh environments.

The core can be either fiber (we call it FC) or independent wire rope (that’s IWRC). Each type gives the final Robustly-Constructed Steel Wire Rope different levels of flexibility and strength.