Kink Resistant Steel Wire Rope

Send Inquiry

To make a Kink Resistant Steel Wire Rope waterproof, two common methods are used: one is zinc plating, and the other is applying a polymer coating to its surface. These treatment methods can prevent water from coming into contact with the wire rope and avoid rusting.

During transportation, we will also wrap the reels with waterproof materials to provide additional protection. However, if the rope needs to be immersed in water for a long time, then you really need to choose the version made of galvanized or stainless steel.

Our packaging ensures that the rope remains dry during transportation and is protected from the effects of rain, humidity, etc.

Product Parameters

|

Specification of stainless steel wire rope |

||||

|

|

||||

|

Product structure |

Specification(mm) |

Tension(kn) |

Load-bearing(kg) |

Reference weight(kg/100m) |

|

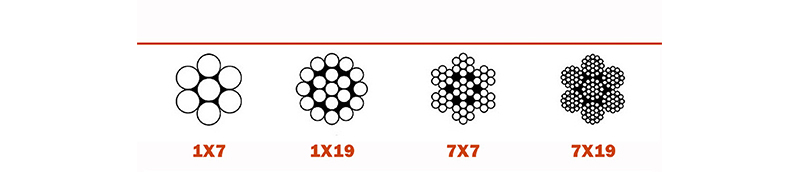

1x7 |

2 | 4.11 | 440 | 2.2 |

| 2.5 | 6.76 | 690 | 3.4 | |

| 3 | 9.81 | 1000 | 4.9 | |

| 3.5 | 13.33 | 1360 | 6.8 | |

| 4 | 17.46 | 1780 | 8.8 | |

|

|

||||

|

Product structure |

Specification(mm) |

Tension(kn) |

Load-bearing(kg) |

Reference weight(kg/100m) |

|

1x19 |

4 | 17.46 | 1780 | 9.1 |

| 5 | 25.49 | 2600 | 14.2 | |

| 6 | 35.29 | 3600 | 20.5 | |

| 7 | 49.02 | 5000 | 27.9 | |

| 8 | 61.76 | 6300 | 36.5 | |

| 10 | 98.04 | 10000 | 57 | |

| 12 | 143.15 | 14500 | 82.1 | |

|

|

||||

|

Product structure |

Specification(mm) |

Tension(kn) |

Load-bearing(kg) |

Reference weight(kg/100m) |

|

7x7 |

1 |

0.56 | 57 | 0.38 |

| 1.2 | 1.13 | 115 | 0.5 | |

| 1.5 | 1.26 | 128 | 0.86 | |

| 1.8 | 1.82 | 186 | 1.3 | |

| 2 | 2.24 | 228 | 1.54 | |

| 2.5 | 3.49 | 356 | 2.4 | |

| 3 | 5.03 | 513 | 3.46 | |

| 4 | 8.94 | 912 | 6.14 | |

|

|

||||

|

Product structure |

Specification(mm) |

Tension(kn) |

Load-bearing(kg) |

Reference weight(kg/100m) |

|

7x19 |

5 | 13 | 1330 | 9.3 |

| 6 | 18.8 | 1920 | 13.4 | |

| 7 | 25.5 | 2600 | 18.2 | |

| 8 | 33.4 | 3410 | 23.8 | |

| 10 | 52.1 | 5310 | 37.2 | |

| 12 | 85.1 | 7660 | 53.6 | |

Product Details

Firstly, we will conduct a quality inspection on the Kink Resistant Steel Wire Rope. The specific approach is to rigorously test the high-carbon steel wire used as raw materials. We will examine its tensile strength and the chemical substances contained within.

During the winding, laying, and sealing processes, we will continuously monitor various indicators using advanced equipment - such as diameter, winding length, and tension. We will also conduct destructive tests on samples of each batch of products. These tests are designed to examine three things: firstly, how much force is required to break the rope; secondly, how resistant the rope is to twisting (i.e., whether it can withstand twisting and resist deformation); and thirdly, whether the rope remains durable and resistant to damage even after repeated use.

This entire system ensures that every meter of the Kink-Resistant Steel Wire Rope meets top performance and safety standards.

FAQ

Q: What is your standard packaging for bulk Kink Resistant Steel Wire Rope orders?

A:For bulk orders, our standard packaging for Kink Resistant Steel Wire Rope uses tough, water-resistant wooden reels or coils. We band them securely to keep them from getting damaged while shipping.

We also use reinforced steel or wooden pallets to make handling easier. Every reel has clear labels—they show product specs, batch number, and length. To address any specific logistics or inventory management needs you may have, we have prepared various packaging solutions that can be implemented according to your requirements, ensuring we meet your needs.