Heavy Duty Steel Wire Rope

Send Inquiry

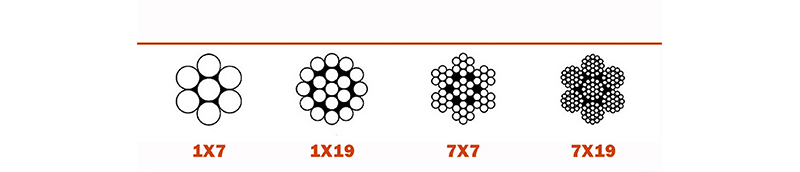

There is a high correlation between the appearance characteristics of Heavy Duty Steel Wire Rope and its specific manufacturing method, and the degree of correlation between the two runs through the entire product production process. This is reflected in key parameters of the manufacturing process – such as the total number of strands in the rope, the number of heavy-duty steel wires in each strand, and the type of material used in the rope core.

A common wire rope is formed by twisting multiple strands of steel wire around a central core. This core can be made of fibers (natural or synthetic) or another independent wire rope. Its outer surface feels very smooth, but in reality, it is composed of the spiral grooves between the steel wires.

You can identify it by observing its diameter, twist direction (conventional twist or Lang's twist), and surface treatment (polished, galvanized, or coated).

Product Advantages

Heavy Duty Steel Wire Rope can offer you significant cost advantages as they are highly durable and have a long service life - this can reduce your overall cost of using them.

Compared to other options (such as synthetic slings), it may have a higher initial cost. However, heavy-duty wire ropes have advantages in compression resistance, wear resistance and high temperature resistance. Due to their long service life, you don't need to replace them frequently, and the downtime is also shorter. Therefore, for industries like mining, house building, and shipping, which usually involve heavy work and have to work non-stop, it is particularly cost-effective to choose it. The money spent is especially worthwhile compared to the effect that can be achieved.

Product Parameters

|

Specification of stainless steel wire rope |

||||

|

|

||||

|

Product structure |

Specification(mm) |

Tension(kn) |

Load-bearing(kg) |

Reference weight(kg/100m) |

|

1x7 |

2 | 4.11 | 440 | 2.2 |

| 2.5 | 6.76 | 690 | 3.4 | |

| 3 | 9.81 | 1000 | 4.9 | |

| 3.5 | 13.33 | 1360 | 6.8 | |

| 4 | 17.46 | 1780 | 8.8 | |

|

|

||||

|

Product structure |

Specification(mm) |

Tension(kn) |

Load-bearing(kg) |

Reference weight(kg/100m) |

|

1x19 |

4 | 17.46 | 1780 | 9.1 |

| 5 | 25.49 | 2600 | 14.2 | |

| 6 | 35.29 | 3600 | 20.5 | |

| 7 | 49.02 | 5000 | 27.9 | |

| 8 | 61.76 | 6300 | 36.5 | |

| 10 | 98.04 | 10000 | 57 | |

| 12 | 143.15 | 14500 | 82.1 | |

|

|

||||

|

Product structure |

Specification(mm) |

Tension(kn) |

Load-bearing(kg) |

Reference weight(kg/100m) |

|

7x7 |

1 | 0.56 | 57 | 0.38 |

| 1.2 | 1.13 | 115 | 0.5 | |

| 1.5 | 1.26 | 128 | 0.86 | |

| 1.8 | 1.82 | 186 | 1.3 | |

| 2 | 2.24 | 228 | 1.54 | |

| 2.5 | 3.49 | 356 | 2.4 | |

| 3 | 5.03 | 513 | 3.46 | |

| 4 | 8.94 | 912 | 6.14 | |

|

|

||||

|

Product structure |

Specification(mm) |

Tension(kn) |

Load-bearing(kg) |

Reference weight(kg/100m) |

|

7x19 |

5 | 13 | 1330 | 9.3 |

| 6 | 18.8 | 1920 | 13.4 | |

| 7 | 25.5 | 2600 | 18.2 | |

| 8 | 33.4 | 3410 | 23.8 | |

| 10 | 52.1 | 5310 | 37.2 | |

| 12 | 85.1 | 7660 | 53.6 | |

FAQ

Q: How do I determine the right grade and construction for my application?

A:Choosing the right Heavy Duty Steel Wire Rope means clearly defining your usage requirements - such as the required strength, flexibility, wear resistance, and whether rust prevention treatment is needed.

For example, the 6x36 wire rope with an IWRC core is very flexible and thus very suitable for use in crane lifting. While the 6x19 wire rope is ideal for general work. We have experts who can assist you - they will guide you in selecting the wire rope grade and type that best suits your specific needs.