China Cotter Pin Manufacturer, Supplier, Factory

Cotter pins, also known as split pins, are fundamental fastening components used to secure parts in a wide range of mechanical and industrial applications. These versatile pins are inserted through a hole and their ends are bent or "split" to lock them in place, preventing the connected parts from coming loose under vibration or rotational forces. They are a simple, cost-effective, and reliable solution for axle retention, clevis pin securing, and many other assembly tasks. For applications requiring different pin geometries, our product line also includes the widely used Round Pin for basic alignment, the Taper Pin for precise positioning in tapered holes, the durable Pin Shaft for high-shear applications, and the self-retaining Spring Pin for assemblies where vibration resistance is paramount. Each of these components serves a distinct purpose, and selecting the right pin is critical for the integrity and safety of your assembly.

To ensure you select the ideal Cotter Pin for your specific needs, it is essential to understand its detailed specifications. The performance of a Cotter Pin is defined by its material composition, dimensions, and finishing. Below are the key parameters presented in both a list and a detailed table for clarity.

- Material: Typically manufactured from carbon steel, stainless steel, or brass.

- Finish: Common finishes include plain, zinc-plated, or passivated for corrosion resistance.

- Diameter: The nominal diameter of the pin wire before forming.

- Length: The overall length of the pin under the head.

- Leg Length & Spread: The length of the two prongs and the angle to which they are pre-bent.

| Material Grade | Standard Finish | Diameter (inches) | Length (inches) | Typical Application |

|---|---|---|---|---|

| Low Carbon Steel (AISI 1010) | Plain / Zinc Plated | 1/16" - 1/2" | 1/2" - 4" | General purpose, low-stress applications |

| Stainless Steel (304/316) | Passivated | 1/16" - 3/8" | 1/2" - 3" | Marine, chemical, and high-corrosion environments |

| Brass | Plain | 1/32" - 1/4" | 1/4" - 2" | Non-magnetic, decorative, and low-spark applications |

Beyond the basic dimensions, the design of a Cotter Pin includes a looped head for easy installation and removal. The prongs are designed to be bent to a specific angle, typically 90 degrees, to ensure a secure lock. The shear strength and resistance to loosening are directly influenced by the material's hardness and the precision of the pin's dimensions. Proper installation is crucial; the prongs should be bent securely around the component without being over-stressed, which could lead to metal fatigue and failure. Always refer to engineering standards, such as those from ANSI or DIN, to confirm the correct Cotter Pin size and material for your application's load and environmental requirements.

Hot Products

Carbon Steel Round Self Clinching Nut

Sourcing specialized fastener requirements is a strength of Xiaoguo.Constructed to common industrial dimensions, the carbon steel round Self clinching nut a robust round body that permanently expands during installation to lock securely into pre-punched or drilled holes.High Strength Weld Hexagon Nut With Flange

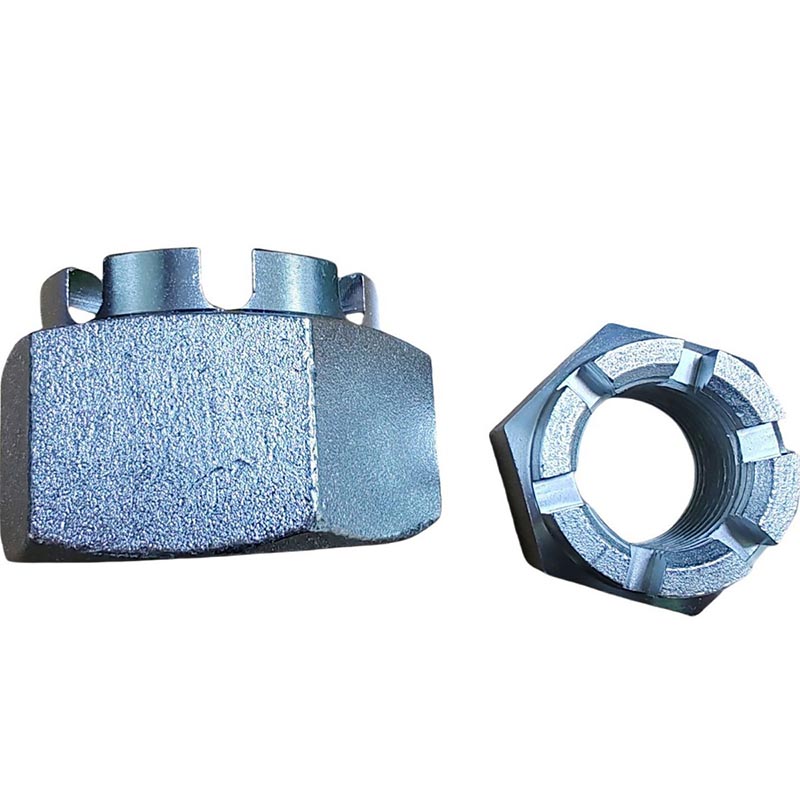

A key advantage of high strength weld hexagon nut with flange is their combination of high pull-out strength, vibration resistance, and ease of alignment during assembly. Xiaoguo® provides competitive pricing and efficient international shipping services. We can provide free samples.Innovatively Designed Crown Nut With Slot

The unique design of the Innovatively Designed Crown Nut With Slot allows for a cotter pin to be inserted through the aligned slot and hole, creating a positive mechanical lock. As a key supplier to the oil and gas industry, Xiaoguo® manufactures fasteners that meet extreme pressure and temperature specifications.User Friendly Hexagonal Wrench

User Friendly Hexagonal Wrench: Xiaoguo®, a professional manufacturer excelling at custom fastener solutions for unique architectural and industrial applications, ensures this tool is made from hardened chrome vanadium steel for strength and wear resistance.Mission Critical Crown Nut With Slot

Mission Critical Crown Nut With Slot, whose manufacturer Xiaoguo® maintains accreditation from major international testing bodies—a testament to its quality systems—is often specified by engineers for applications where a secure, vibration-proof fastening is essential for safety.Cup oval neck bolts for fish plate

The Cup oval neck bolts for fish plate produced by Xiaoguo® Company has undergone precise processing. They ensure a firm connection of the tracks and reduce the risk of derailment. If you want to test the quality, then we can send free samples.