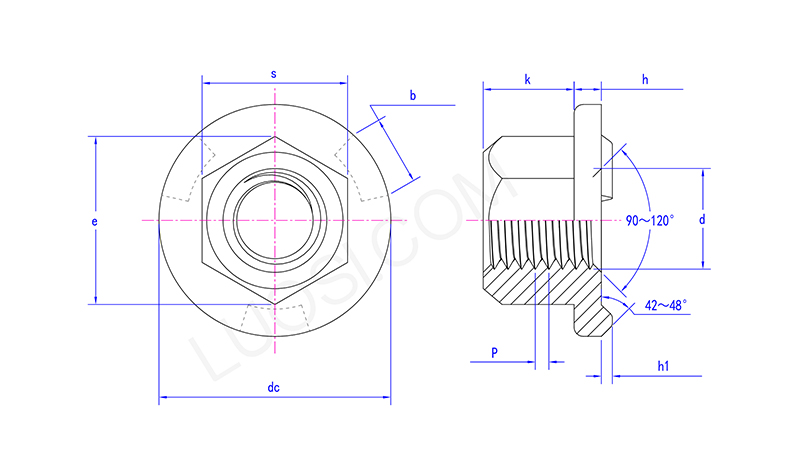

High Strength Weld Hexagon Nut With Flange

Send Inquiry

Carbon steel high strength weld hexagon nut with flange usually fit grades like 5, 8, or 10 (from ASTM A563) or similar ISO property classes—like 8, 10, 12. This makes sure they have specific mechanical properties. The stainless steel ones generally meet ASTM A194/A194M or ASME standards, which cover their chemical makeup and how well they resist corrosion, stuff that matters for these nuts.

| Mon | M8 | M10 | M12 | M14 |

| P | 1.25 | 1.5 | 1.75 | 2 |

| h1 max | 1.1 | 1.3 | 1.3 | 1.3 |

| h1 min | 0.9 | 1.1 | 1.1 | 1.1 |

| dc max | 22.5 | 26.5 | 30.5 | 33.5 |

| dc min | 21.5 | 25.5 | 29.5 | 32.5 |

| e min | 13.6 | 16.9 | 19.4 | 22.4 |

| h max | 2.75 | 3.25 | 3.25 | 4.25 |

| h min | 2.25 | 2.75 | 2.75 | 3.75 |

| b max | 6.1 | 7.1 | 8.1 | 8.1 |

| b min | 5.9 | 6.9 | 7.9 | 7.9 |

| k min | 9.64 | 12.57 | 14.57 | 16.16 |

| k max | 10 | 13 | 15 | 17 |

| s max | 13 | 16 | 18 | 21 |

| s min | 12.73 | 15.73 | 17.73 | 20.67 |

Precautions:

Putting high strength weld hexagon nut with flange in properly means using the right welding steps. The nut needs to be set in the right spot and held tight against the workpiece surface—make sure that surface is clean and ready first. For projection welding, you’ve got to use the correct current, timing, and pressure. For arc welding, it’s about the right technique. Either way, getting this right is important. You need a weld that goes all the way through, but without messing up the nut’s threads. That’s how you make sure the joint holds up.

Installation Instructions:

To projection high strength weld hexagon nut with flange with a flange, you usually need a special resistance welder. It has to have the right electrode pressure, current, and timing settings that work for the nut's size and material. Check the manufacturer's info sheet for the suggested settings that fit your specific nuts.