Precision Metalworking Parallel Pins

Send Inquiry

Precision Metalworking Parallel Pins is a precision locating element widely used in machinery manufacturing, automotive, aerospace and other fields. It has the characteristics of simple structure, good alignment, high load carrying capacity, excellent performance of variable load and impact, etc.

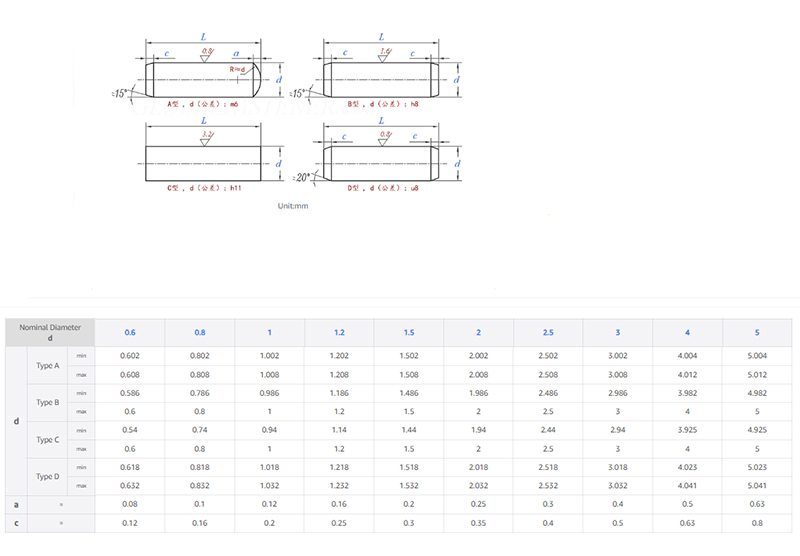

Product types

Plain Cylindrical Pins

Cylindrical pins with internal thread

Threaded Cylindrical Pins

Cylindrical pins with hole

Cylindrical pins with elasticity

Product advantages

Precision Metalworking Parallel Pins have simple structure, good alignment, high load carrying capacity, good performance of variable load and impact, but require high machining accuracy of the mating surface.

Precision Metalworking Parallel Pins have high dismantling force, which will scratch the mating surface, and belong to the non-detachable connection.

Precautions

Precision Metalworking Parallel Pins are non-detachable connections, which may scratch the mating surfaces during disassembly, so it is generally not recommended to reuse them so as not to affect the assembly accuracy and reliability.

When selecting the size of the cylindrical pin, it needs to be determined according to the specific assembly requirements and force conditions. In general, the size of the mating hole, the required load capacity, installation space and other factors need to be considered to ensure that the cylindrical pin can meet the use of demand.