Understanding Clamp Nuts: Secure Fastening Solutions

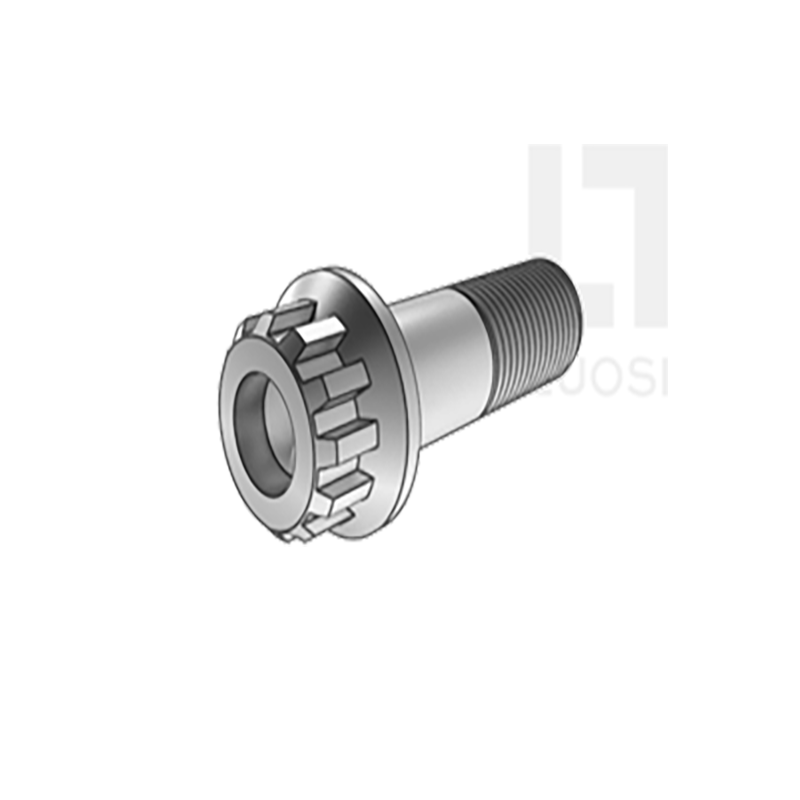

For robust and reliable fastening in demanding applications, the clamp nut is a cornerstone component. Designed to maintain tension and resist loosening under vibration and dynamic loads, these specialized nuts are essential in industries ranging from automotive and aerospace to heavy machinery and construction. A clamp nut functions by creating a powerful clamping force that secures components firmly together. This makes it an excellent alternative or complementary solution to other vibration-resistant fasteners, such as the widely-used self-locking nut. While both a self-locking nut and a clamp nut aim to prevent accidental disassembly, their mechanisms can differ, offering engineers and designers a range of options to achieve optimal joint integrity. The primary advantage of a high-quality clamp nut is its ability to deliver consistent preload, ensuring a secure connection that endures the rigors of its operating environment.

The Clamp Nut is engineered with precision to meet rigorous industry standards. Its design typically incorporates specific features that enhance its performance. These nuts are available in various materials, sizes, and configurations to suit a vast array of technical requirements and specifications. Below is a detailed breakdown of the typical parameters and technical data for our standard Clamp Nut product line.

Key Features of the Clamp Nut:

- High-Strength Alloy Steel Construction

- Zinc-Plated or Hot-Dip Galvanized Finish for Corrosion Resistance

- Precision-Machined Threads for Smooth Engagement

- Wide Bearing Surface for Distributed Load

- Designed to Withstand High Vibration and Shock Loads

Detailed Product Specifications:

| Parameter | Specification / Value |

|---|---|

| Thread Sizes (Metric) | M6, M8, M10, M12, M16, M20, M24 |

| Thread Sizes (Imperial) | 1/4"-20, 5/16"-18, 3/8"-16, 1/2"-13, 5/8"-11, 3/4"-10 |

| Material Grades | Grade 5, Grade 8, AISI 304 Stainless Steel, AISI 316 Stainless Steel |

| Proof Load (MPa) | 830 MPa (for Grade 8 Steel) |

| Tensile Strength (MPa) | 1040 MPa (for Grade 8 Steel) |

| Hardness (HRC) | 24 - 32 HRC |

| Temperature Range | -50°C to +300°C (dependent on material and coating) |

| Standard | DIN, ISO, ANSI, ASME |

Hot Products

Reed Nut for Automobile

Reed nut for automobile is a type of nut designed specifically for key components such as engines and chassis.Xiaoguo® is a professional foreign trade company in the field of fasteners, which can not only independently develop advanced production processes, but also meet the customized needs of different customers, providing one-stop solutions for customers in the furniture, machinery manufacturing and other industries.Carbon Steel US Round Wing Nuts

The carbon steel US round wing nuts produced by Xiaoguo® are made of carbon steel and are suitable for harsh environments such as mechanical, automotive and structural applications that require frequent disassembly and high tensile strength.Technologically Advanced Aircraft Steel Wire Rope

Technologically Advanced Aircraft Steel Wire Rope features in custom-engineered cable assemblies from Xiaoguo®, a supplier providing precision swaging and specialized terminations. Strict SAE-AS standards govern its production and quality control.DIN529 Type E Anchor Bolts

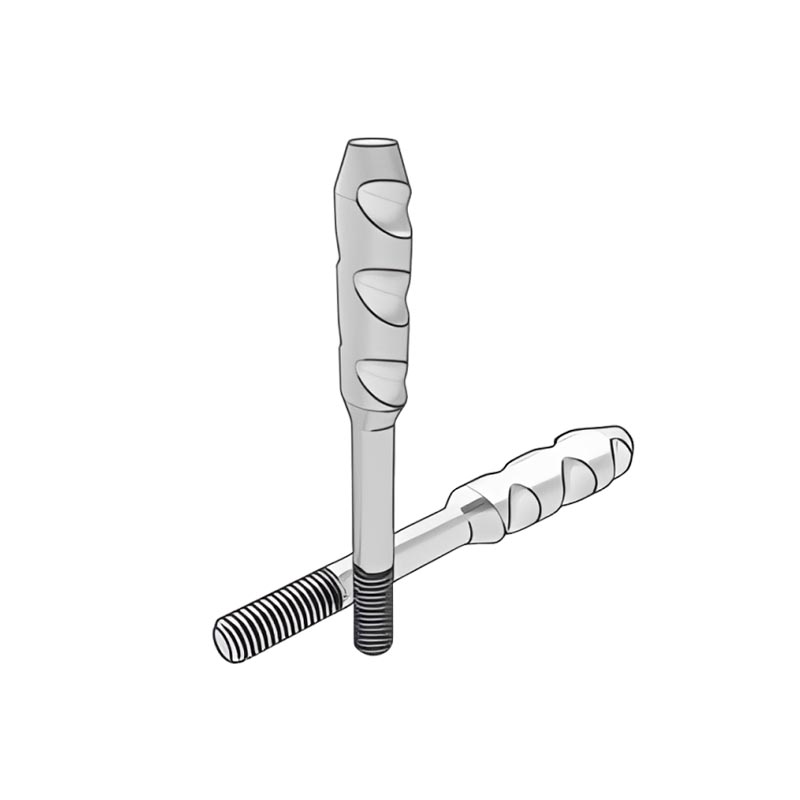

One end of the DIN529 type E anchor bolts are unusually shaped, with multiple recessed areas. The other end features short threads for easy fastening and removal. The Xiaoguo® factory can send samples for testing, and we can ensure fast delivery.Rough Pole Double Studs With Fine Pitch

Rough pole double studs with fine pitch is suitable for scenarios that require high-strength and precise connections. The thick rod enhances the grip, while the fine thread ensures a tight and stable fit. The Xiaoguo® factory has a large amount of inventory in stock.Tooth Star Lock Washer

The tooth star lock washer is a commonly used accessory in the machinery manufacturing industry. The tooth star lock washer is fixed on the base of the bearing of heavy machinery and equipment, and the clamping angle and position are adjusted to tighten the bearing.Xiaoguo® is a factory specialized in manufacturing Washer.