Wire Thread Insert

Send Inquiry

Wire thread inserts are used in a lot of different industries. In aerospace and defense, they help strengthen threads in aluminum and magnesium parts. Automotive and racing setups use them in engine blocks and transmission cases. They’re important for marine gear, plastic molding machines, industrial machinery repairs, electronics cases, and any situation where soft metals, plastics, or composite materials need strong, reusable threaded holes. Basically, if there’s a thread failure problem, they are a go-to solution across the board.

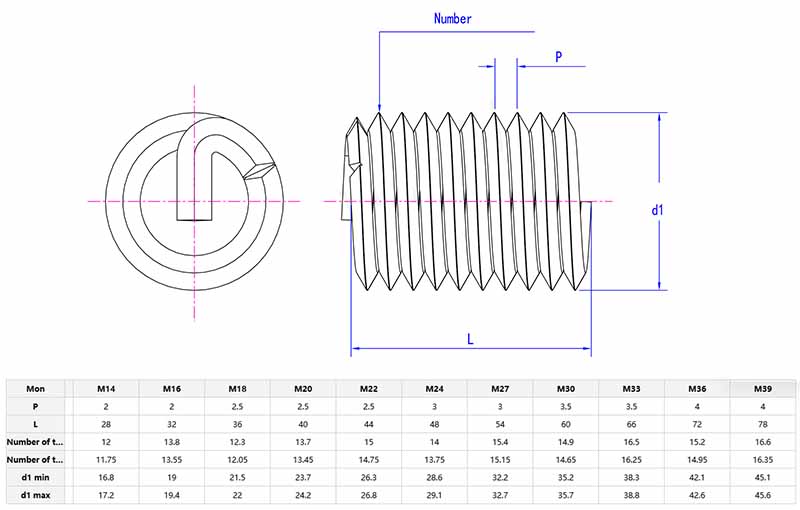

Product details and parameters

Wire thread inserts often get coatings to make them work better. Common coatings include things like Xylan, which is a dry lubricant that cuts down friction and torque when you’re installing them. Cadmium plating is another option—it’s good at fighting corrosion and is often used in aerospace setups. Silver plating helps prevent threads from sticking together at high temperatures, and nickel plating offers general rust protection. These coatings on this stop them from seizing up, make them easier to install, add the rust protection they need, and help them last longer in rough environments where they’re used.

FAQ

Q: Is the installation process for this complicated and does it require special tools?

A: Installing a Wire Thread Insert needs a couple of specific tools you can get easily: an oversized special tap for the hole and a mandrel to drive the insert in. It's manageable if you have some experience and the right gear, but you've gotta follow the maker's instructions closely – right tap size, correct hole depth, and proper mandrel setup. Doing it right means the insert seats properly, the tang snaps off clean, and you get the full thread strength. You can find kits that include all the necessary stuff.