Aluminum Alloy Round Self Clinching Nut

Send Inquiry

The stuff your aluminum alloy round self clinching nut really affects how tough it is and what jobs it can handle. The carbon steel ones usually come in grades like 8.8, 10.9, or 12.9. Those grades are strong, so they hold up well under heavy loads without breaking.

For stainless steel nuts: AISI 304 (sometimes called A2) is decent for stopping everyday rust. If you need something better against stuff like saltwater or chemicals, go for AISI 316 (A4). Aluminum nuts often use mixes like 5056 (AlMg5),it's strong and handles seawater pretty well. If you need even more strength, they use 7075 (AlZn5.5MgCu).

Most times, you can ask for a material certificate (like a Mill Cert). That paperwork shows the actual metal mix and proves the strength meets the standard. It lets you double-check you're getting the right Expanded rivet round nut for what you're building.

Install:

Start by drilling a hole in your material. Get the hole size right for the aluminum alloy round self clinching nut you're using. Then just pop the nut into the hole from the side you can access.

Now, grab a setting tool made for that nut size. Basically, it's a bolt that screws into the nut's threads. You can run this tool with a regular rivet gun or a hydraulic/pneumatic puller. When you operate the tool, it yanks the bolt (the mandrel) back through the nut. This pulling action forces the nut's body into its sleeve, making the sleeve push outwards. This pushes out a flange on the backside (the side you can't see), and that flange squeezes the material tight.

Once that's done, simply unscrew the tool bolt. What you've got now is a solid threaded hole inside the material, locked in place for good.

How to choose the right nut according to the diameter and wall thickness of the pipe?

Picking the right Expanded rivet round nut-Aluminum alloy,you'll need two things about your tube: the exact inside hole size (ID) and the wall thickness. Manufacturers have charts where you match up your tube's numbers to the nut size (like M6 or M8).

Every aluminum alloy round self clinching nut fits only a very specific range of tube sizes and wall thicknesses. If you use one that doesn't match your tube, it just won't hold right – the connection won't be secure. So always check the specs first. Grabbing the wrong nut for your tube will cause problems.

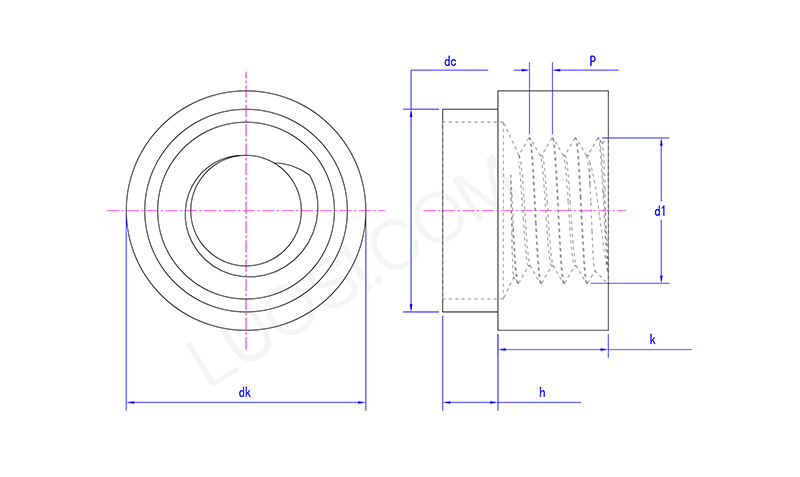

| Mon | M3-1.5 | M3-2 | M4-1.2 | M4-1.5 | M4-2 | M5-2 | M5-3 | M6-2 | M6-3 | M8-2 | M8-3 |

| P | 0.5 | 0.7 | 0.7 | 0.7 | 0.7 | 0.8 | 0.8 | 1 | 1 | 1.25 | 1.25 |

| dk max | 7.25 | 7.25 | 8.25 | 8.25 | 8.25 | 10.25 | 10.25 | 11.25 | 11.25 | 13.25 | 13.25 |

| dk min | 6.75 | 6.75 | 7.75 | 7.75 | 7.75 | 9.75 | 9.75 | 10.75 | 10.75 | 12.75 | 12.75 |

| dc max | 4.98 | 4.98 | 5.98 | 5.98 | 5.98 | 7.95 | 7.95 | 8.98 | 8.98 | 10.98 | 10.98 |

| k max | 3.25 | 3.25 | 4.25 | 4.25 | 4.25 | 5.25 | 5.25 | 6.25 | 6.25 | 6.25 | 6.25 |

| k min | 2.75 | 2.75 | 3.75 | 3.75 | 3.75 | 4.75 | 4.75 | 5.75 | 5.75 | 5.75 | 5.75 |

| h max | 1.6 | 2.1 | 1.3 | 1.6 | 2.1 | 2.1 | 3.1 | 2.1 | 3.1 | 2.1 | 3.1 |

| h min | 1.4 | 1.9 | 1.1 | 1.4 | 1.9 | 1.9 | 2.9 | 1.9 | 2.9 | 1.9 | 2.9 |

| d1 | M3 | M3 | M4 | M4 | M4 | M5 | M5 | M6 | M6 | M8 | M8 |