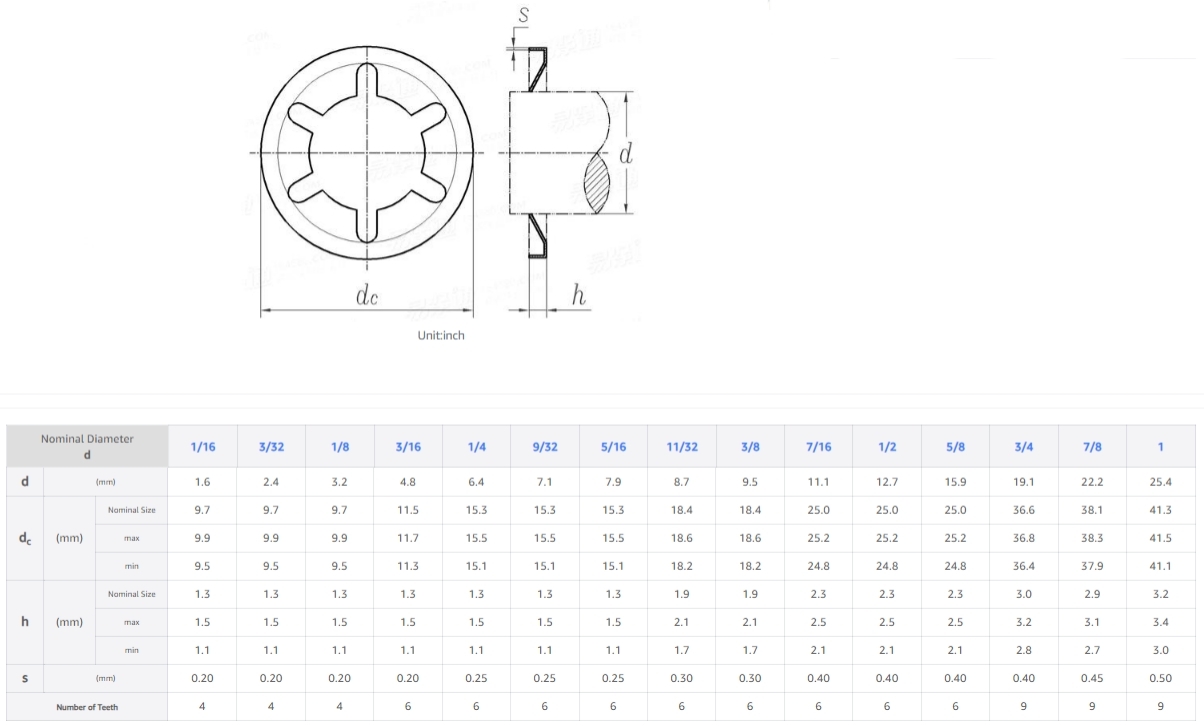

Tooth Star Lock Washer

Send Inquiry

Tooth star lock washer can easily clamp and accurately mount the bearings to the specified position by virtue of its unique star-shaped structural design.Its multi-point uniform force characteristics ensure that the bearing will not be damaged in the installation process,while providing a stable and reliable clamping effect,greatly improving the efficiency and quality of bearing installation.

Installation steps

1. Place the tooth star lock washer in the bearing mounting position, make sure that the clamping part and the bearing are closely fitted, adjust the angle and position of clamping so that the bearing can be uniformly loaded to avoid deformation or damage of the bearing caused by excessive local pressure.

2. Slowly rotate the handle, so that the clamping jaws gradually shrink inward, uniformly clamp the bearing, until the bearing is firmly fixed in the installation position, and at the same time pay attention to observe the bearing's force situation, to ensure that it is installed in the process of maintaining a smooth, does not occur offset or shaking.

3.In the installation process of the tooth star lock washer,the clamping strength and angle can be adjusted appropriately according to the specific needs and equipment conditions, in order to achieve the best installation effect, to ensure that the bearing is installed firmly and accurately, and to provide a strong guarantee for the stable operation of the equipment.

Advantages

Tooth star lock washer is extremely easy to operate, users only need to easily rotate the handle, you can quickly adjust the clamping size, closely fit the different specifications of the bearing, without the need for cumbersome operating steps and professional skills, greatly reducing the preparation time before installation, so that the bearing installation work is more fluent and efficient, and effectively enhance the efficiency of the work.

Application

With its unique design and excellent performance, the tooth star lock washer is suitable for a variety of working environments. In the field of automobile maintenance, it can quickly and accurately install various types of bearings and improve maintenance efficiency. In machinery manufacturing, it is suitable for a variety of bearing models to meet the needs of production lines. In the installation and maintenance of industrial equipment, it can cope with harsh conditions and ensure the correct installation of bearings. In addition,it is also widely used in aerospace, electronics and electrical appliances, railroad locomotives and other fields, providing efficient solutions for bearing mounting in various industries.