Industrial Grade Lifting Eye Nut

Send Inquiry

In the warehouse, the Industrial Grade Lifting Eye Nut are indeed very convenient for handling heavy objects - whether for storing these items or moving them. When new goods arrive, such as pallets filled with tools or metal parts, workers will attach a lifting ring to the sturdy part of the pallet. Then they can fix it on a forklift or a crane, and directly move all the items to the shelves.

And the same is true during the shipping process: These nuts make the operation of moving heavy objects from the high shelves to the loading area safe and reliable.

Their practicality is particularly evident in busy warehouse environments. Warehouse operations require extreme speed, and these tools, requiring only simple tightening operations, can significantly save man-hours compared to other lifting methods. Furthermore, their robust construction is durable enough to withstand frequent daily use.Even if there are dust or occasional collisions in the storage space, they will remain intact.

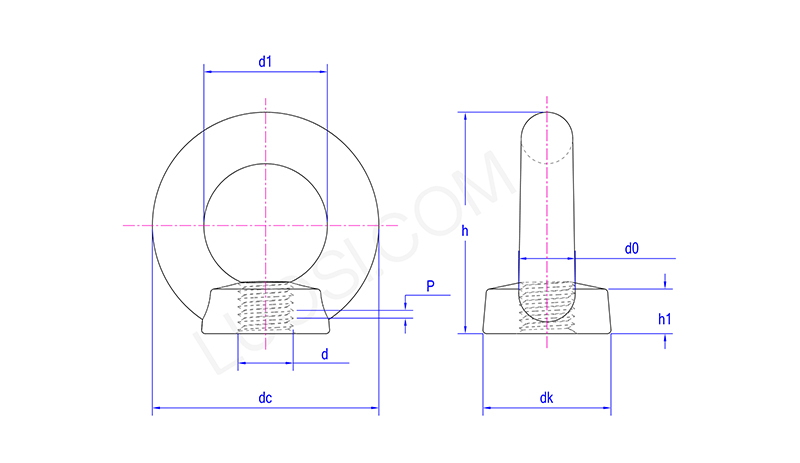

| Mon | M8 | M10 | M12 | M16 | M20 | M24 | M30 | M36 | M42 | M48 | M56 |

| P | 1.25 | 1.5 | 1.75 | 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 |

| dk min | 19.5 | 24.5 | 29.5 | 34.4 | 39.4 | 49.3 | 64.3 | 74.6 | 84.3 | 99.2 | 108.9 |

| dk max | 20.9 | 26.1 | 30.4 | 36.2 | 41.2 | 51.3 | 66.3 | 76.5 | 86.5 | 101.7 | 112.1 |

| dc min | 35.5 | 44.4 | 53.5 | 62.4 | 71.4 | 89.3 | 107.3 | 125.2 | 143.2 | 164.9 | 182.8 |

| dc max | 37.1 | 46.2 | 55.1 | 64.2 | 73.2 | 91.3 | 109.5 | 127.7 | 145.7 | 168.1 | 186.4 |

| d1 min | 19.1 | 23.9 | 29.1 | 33.8 | 38.8 | 48.7 | 58.7 | 68.5 | 78.5 | 88.3 | 98.1 |

| d1 max | 20.5 | 25.5 | 30.5 | 35.6 | 40.6 | 50.7 | 60.7 | 70.7 | 80.7 | 90.8 | 100.9 |

| h1 min | 8 | 9.5 | 10.5 | 12.5 | 15.5 | 19.4 | 24.4 | 29.3 | 34.3 | 39.2 | 44.1 |

| h1 max | 9.4 | 11.1 | 11.9 | 14.1 | 17.1 | 21.2 | 26.2 | 31.3 | 36.5 | 41.7 | 46.9 |

| h min | 35.5 | 44.4 | 52.5 | 61.4 | 70.4 | 89.3 | 108.3 | 127.2 | 146.2 | 166.9 | 185.9 |

| h max | 37.1 | 46.2 | 54.1 | 63.2 | 72.2 | 91.3 | 110.5 | 129.7 | 148.7 | 170.1 | 189.4 |

| d0 min | 9.5 | 11.5 | 13.5 | 15.5 | 18.5 | 23.4 | 27.4 | 31.3 | 37.3 | 45.2 | 49.1 |

| d0 max | 10.9 | 13.1 | 14.9 | 17.1 | 20.1 | 25.2 | 29.2 | 33.3 | 39.5 | 47.7 | 51.9 |

Product Benefits

The operation of a Industrial Grade Lifting Eye Nut is very simple - it consists of two main parts: the threaded bottom part and the circular top part. The bottom part has threads - common sizes include M10 or M16, or possibly ½ inch - so it can be directly screwed into pre-drilled holes in metal, wood or plastic. The circular top part (also known as the "hook") is usually a smooth circle or oval, so it won't scratch or catch hooks when lifted.

Some versions also have a guard ring below the eye. Once it is tightened, it can provide additional support. And unlike ordinary nuts, this "eye" part is designed to be thicker and stronger because it needs to bear all the weight. The entire structure is also very compact, so it won't interfere in a narrow space.

Main Materials

We mainly use high-grade carbon steel and stainless steel (such as 304/316) to manufacture " Industrial Grade Lifting Eye Nut ". Carbon steel has good general strength, while stainless steel can provide excellent corrosion resistance in harsh environments, thus ensuring the durability and long-term reliability of the product.