Forged Eye Nut

Send Inquiry

Good quality Forged Eye Nut have certifications from around the world, like CE, DNV-GL, or OSHA compliance. These show they meet load-testing rules, like proof testing at twice the WLL (Working Load Limit). Look for engraved labels on them that say the grade, WLL, and who made them. CE-certified ones follow the EU Machinery Directive 2006/42/EC. Those used in marine settings often have Lloyd’s Register approval.

Don’t buy uncertified ones—they might not have proper batch testing records. Independent certifications make sure lifting eye nuts can handle fatigue, shocks, and extreme temperatures. For high-risk jobs, like in aerospace or nuclear places, always ask for test reports to be sure they’re safe.

Product details

Modern Forged Eye Nut have smart features like RFID tags built in for tracking inventory. Some designs are easier to use, with non-slip grooves or lightweight materials. There are also models that combine eye nuts with swivel hoist rings, so you can lift from different angles. Some brands care about the environment and make them from recycled steel to cut down on carbon footprints.

FAQ

Q: How do I properly install the Nut to avoid threading or alignment issues?

A: Match the thread types of the threaded holes and nuts on the installed components, then to install Forged Eye Nut safely. The first step is to thoroughly clean the threads and remove dirt and debris and the second step is to manually tighten it to avoid cross-threading. We recommended to use a torque wrench to tighten it to the specification recommended by the manufacturer. over-tightening can strip the threads, and under-tightening can make them slip under load.

Line up the eye’s direction with where the load will be going to avoid extra side stress. If the load needs to rotate, use the swivel hoist ring with the eye nut. Lubricate the threads regularly to prevent jamming.

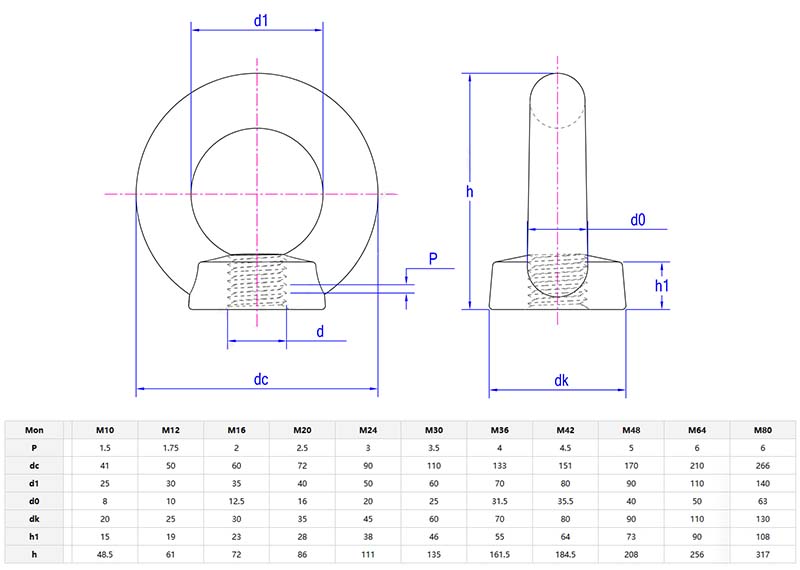

Product parameters