Eye Nut

Send Inquiry

Eye Nut is made from high - grade alloy steel or stainless steel, and they have a good strength - to - weight ratio. Heat - treated alloy types can get tensile strengths over 100,000 psi, which is suitable for heavy - duty lifting jobs. Stainless steel Hoist Nut can stand up to rust, acids, and rough environments, making them a good fit for marine or chemical industries. The forging process gets rid of air holes, so the structure is strong and even. Some models use ductile iron to soak up shocks. There are material certifications like ISO 9001 to make sure the quality is consistent. Whether it’s really cold or really hot, Eye Hoist Nut keep working well and don’t deform easily. Choose the material based on how much weight you need to lift and what kind of environment they’ll be in.

Product details

Eye Nut get surface treatments to help them last longer. Common ones include hot-dip galvanizing. They can add a thick zinc layer that holds up well to wear, good for outdoor use. Electroplated coatings give them a smoother finish, which is handy for indoor jobs that need precision. Powder coating can add different colors and protect against UV rays. For marine setups, stainless steel Hoist Nut get passivated to fight saltwater corrosion. Black oxide coatings cut down on glare and make them slide better (improve lubricity). These finishes don’t just protect against wear—they also make cleaning easier. Always check if the coating works with where you’re using them to avoid the nuts wearing out too fast.

FAQ

Q: How do I determine the correct WLL (Working Load Limit) for Eye Nut in my application?

A: The WLL of Nut is based on thread diameter, material grade (like Grade 8 or 316 stainless steel), and how much you’re lifting at an angle. When lifting straight up, use the WLL listed by the maker, which is usually 25-30% of the lowest weight that would break it. If you’re lifting at an angle, lower the WLL by a percentage—for example, a 45-degree angle cuts capacity by 30%. Always account for safety buffers in case of sudden pulls or temperature changes. Check our tech sheets for exact numbers, and never go over the WLL marked on the nuts.

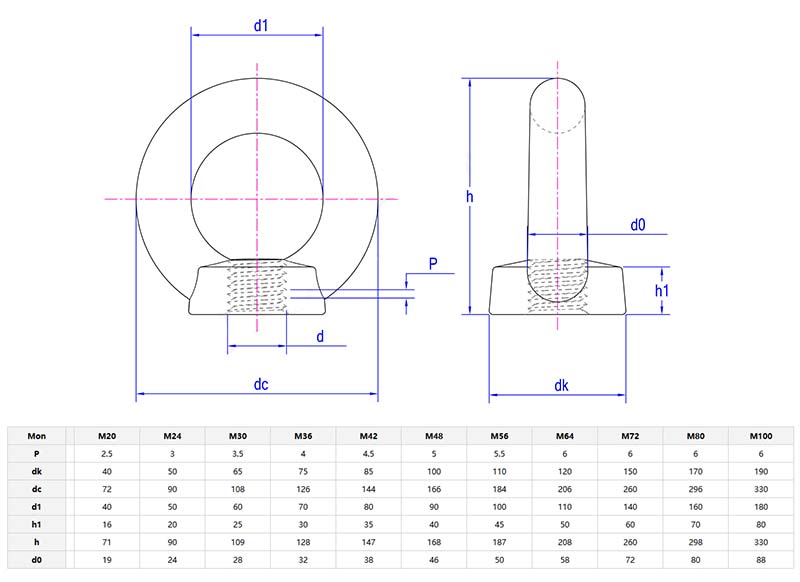

Product parameters