Engineered Lifting Eye Nut

Send Inquiry

Engineered Lifting Eye Nut if you need fasteners for industrial projects, Xiaoguo® has a wide range—from standard steel bolts to specialized aerospace-grade washers, all supplied by trusted manufacturers. This type of fastener features a looped top, designed to attach to heavy objects so they can be lifted safely with tools like cranes or hoists.On construction sites, a Engineered Lifting Eye Nut is commonly used to lift heavy objects such as steel beams, concrete blocks and metal frames. Workers simply need to screw it into the threaded holes on the materials, and then use the ring structure to lift the crane or crane truck, thus safely lifting all the items.

This is a convenient method for moving large items on the site, as it can distribute the weight and help prevent slipping. Unlike ordinary hooks, this threaded connection method ensures that the items are firmly fixed - so there will be no accidental drops of items, thus avoiding injuries or delays.

You will find that these nuts are widely used in various projects, from skyscrapers to small ones. As long as there are tasks requiring efficient and safe handling of heavy objects, they will be used.

Applicable Scenarios

In manufacturing plants, Engineered Lifting Eye Nut are indeed very practical and can be used to move heavy machine components and finished products. For example, when assembling large equipment (such as printing machines or assembly line machines), workers will use these nuts to lift and position heavy components such as metal gears, motors or covers.

They are also particularly suitable for transporting completed items (such as large appliances or metal containers) from the production line to the warehouse.

People use lifting lug devices here because they can bear very heavy industrial items (usually up to several hundred kilograms), and can be used in conjunction with factory bridge cranes and other lifting equipment, making the operation very convenient. This not only speeds up the workflow, but also reduces the need for people to manually carry heavy objects, thereby ensuring the safety of the working environment.

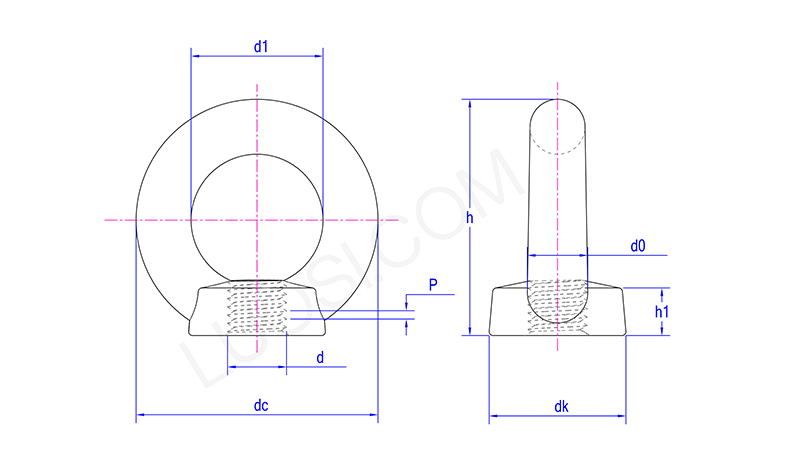

| Mon | M8 | M10 | M12 | M16 | M20 | M24 | M30 | M36 | M42 | M48 | M56 |

| P | 1.25 | 1.5 | 1.75 | 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 |

| dk | 20 | 25 | 30 | 35 | 40 | 50 | 65 | 75 | 85 | 100 | 110 |

| dc | 36 | 45 | 54 | 63 | 72 | 90 | 108 | 126 | 144 | 166 | 184 |

| d1 | 20 | 25 | 30 | 35 | 40 | 50 | 60 | 70 | 80 | 90 | 100 |

| h1 | 8.5 | 10 | 11 | 13 | 16 | 20 | 25 | 30 | 35 | 40 | 45 |

| h | 36 | 45 | 53 | 62 | 71 | 90 | 109 | 128 | 147 | 168 | 187 |

| d0 | 10 | 12 | 14 | 16 | 19 | 24 | 28 | 32 | 38 | 46 | 50 |

FAQ

Question: What safety standards do your Engineered Lifting Eye Nuts comply with?

Answer: Produced in accordance with international safety standards such as ISO 3266 and ASME B30.26, hook nuts offer reliable performance for your specific lifting applications. Full traceability and quality assurance provide added peace of mind.