Bolt Fastened Shaft Collar

Send Inquiry

The bolt fastened shaft collar uses regular alloy steel or stainless steel. These materials make it hold up well under pressure and avoid rusting. They heat-treat the surface to toughen it up – hitting around 45-50 HRC hardness (so it doesn’t warp when you push it hard). Stainless steel types handle messy conditions better, like places with chemicals or moisture, since they rust less. The metal also handles repeated stress without wearing out quickly. Because it’s both stiff and slightly bendy, you’ll find these collars in stationary gear, moving parts, and even stuff that runs in extreme hot or cold temps.

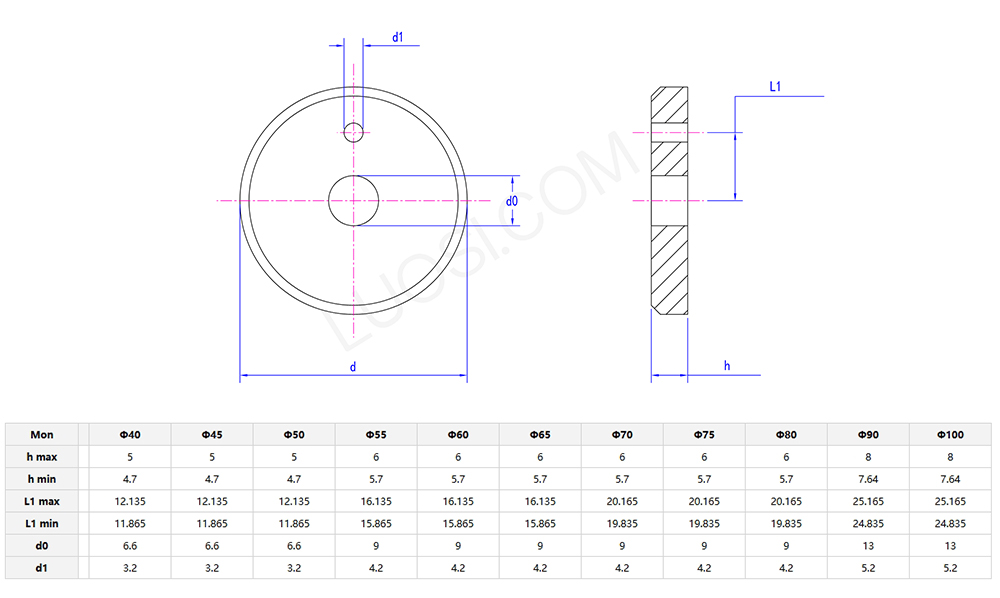

Product details and parameters

Bolt fastened shaft collar are widely used in automotive gearboxes, industrial pumps, conveyor belt equipment, and moving aerospace parts. As a fixture for parts on the shaft, it can effectively lock parts such as pulleys, sprockets, and couplings on the shaft to prevent axial sliding during operation. Especially in equipment such as engines and turbines, its anti-vibration structural design is of great significance and can ensure the stable operation of the equipment.

Retaining rings are also very useful in agricultural machinery, robotics, and renewable energy devices such as wind turbines. Under high-speed rotation conditions, it can ensure the safety of components through reliable fixing performance. Therefore, in industries with extremely high requirements for precision and reliability, bolt-on collars have become an indispensable core part.

If you have such a question

Q: What materials are bolt fastened shaft collar typically made from, and how do they impact durability?

A: Bolt fastened shaft collar are typically made from carbon steel, stainless steel, or alloy steel. Carbon steel’s cheaper and works fine for most factory equipment, while stainless steel resists rust better – good for wet areas or places with chemicals (like boats or chemical plants). Alloy steel ones get heat-treated to handle heavy wear and last longer. What material you choose decides the collar’s lifespan, how much load it can take, and where it’ll work. Just tell them where you’ll use it – like if it’ll get hot, wet, or carry heavy loads – so they match the material right.