Top Projection Weld Screw

Send Inquiry

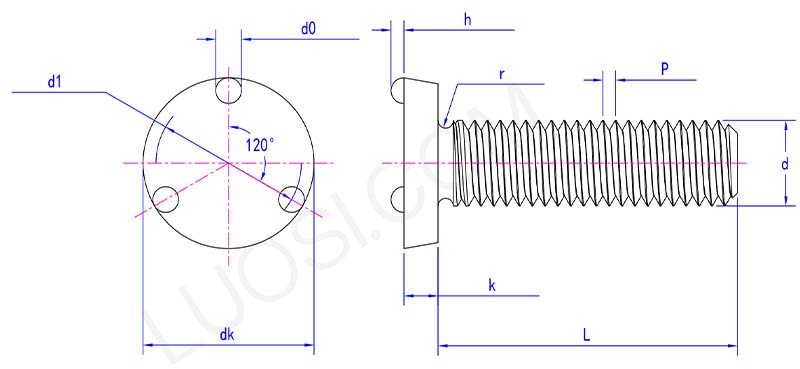

The top projection weld screw is mainly composed of a screw and a head with a protruding welding platform. The screw part has standard threads, and on the top there are a specific number and shape of welded protrusions, which are all of the same height.

Advantage and Applications

This nibs over head projection weld screw is both strong and efficient. During the welding process, the current is concentrated on the convex welding platform, which enables the bolts and the welded parts to be firmly connected together in a much shorter time than with ordinary welding methods. The three convex welding stations can help the bolts automatically find their correct positions.

Top projection weld screws are used in the automotive manufacturing industry. In the production of car bodies, this type of bolt is widely used to connect various components. For example, in the installation of car seats. First, the bolt is welded to the car body through protruding welding. Then, the installation holes of the seat are aligned with the bolt, and a nut is tightened to securely fix the seat, ensuring that the seat will not shake during the car's movement.

|

Mon |

M4 | M5 | M6 | M8 | M10 | M12 |

|

P |

0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 |

|

dk max |

11.5 | 12.5 | 14.5 | 19 | 21 | 24 |

|

dk min |

11.23 | 12.23 | 14.23 | 18.67 | 20.67 | 23.67 |

|

k max |

2 | 2.5 | 2.5 | 3.5 | 4 | 5 |

|

k min |

1.75 | 2.25 | 2.25 | 3.25 | 3.75 | 4.75 |

|

r min |

0.2 | 0.2 | 0.3 |

0.3 |

0.4 | 0.4 |

|

d1 max |

8.75 | 9.75 | 10.75 | 14.25 | 16.25 | 18.75 |

|

d1 min |

8.5 | 9.5 | 10.5 | 14 | 16 | 18.5 |

|

h max |

1.25 | 1.25 | 1.25 | 1.45 | 1.45 | 1.65 |

|

h min |

0.9 | 0.9 |

0.9 |

1.1 | 1.1 | 1.3 |

|

d0 max |

2.6 | 2.6 | 2.6 | 3.1 | 3.1 | 3.6 |

|

d0 min |

2.4 | 2.4 | 2.4 | 2.9 | 2.9 | 3.4 |

Product Features

The most distinctive feature of the top projection weld screw is its unique protruding welding platform at the head. These spot welding machines have regular shapes and uniform sizes. During the welding process, they can precisely concentrate the current, ensuring a stable and reliable welding result with guaranteed welding quality. Due to the presence of the convex welding station, the damage to the surface of the welded parts during the welding process is relatively small, and the appearance and performance of the welded parts can be better maintained.