Projection Underweld Screw

Send Inquiry

The head of projection underweld screw is in the shape of a round plate, simple and regular; the screw is straight, and the surface has uniform and continuous threads, which are used to cooperate with nuts and other components to achieve tightening. The overall design is simple and practical.

Applications

This underweld screw is used in general mechanical assembly. For example, equipment such as machine tools and agricultural machinery are used to connect the casing, base, and non-critical transmission components. Their stability ensures the smooth operation of the equipment.

Projection underweld screw is used in the furniture manufacturing industry. During the assembly of tables, chairs and cabinet bodies, the fixed panels and frames are securely fixed. The round heads are not protruding, avoiding scratches and ensuring the safety and aesthetics of daily use. They can also be used for repairing buildings. Temporary buildings, light steel structures, or fixing of doors and windows, as well as fences, can be quickly connected using these methods to meet the requirements of foundation load-bearing and installation.

Projection weld screw is firmly welded and has a stable connection. Through the welding method, the bolt can be closely combined with the welded part, forming a very strong connection strength. It is less likely to loosen than ordinary bolt connections. They increase the contact area with the welded part. When tightening the nut, they can more evenly distribute the pressure and reduce the pressure on the surface of the welded part, preventing the welded part from being damaged or deformed.

Product parameters and features

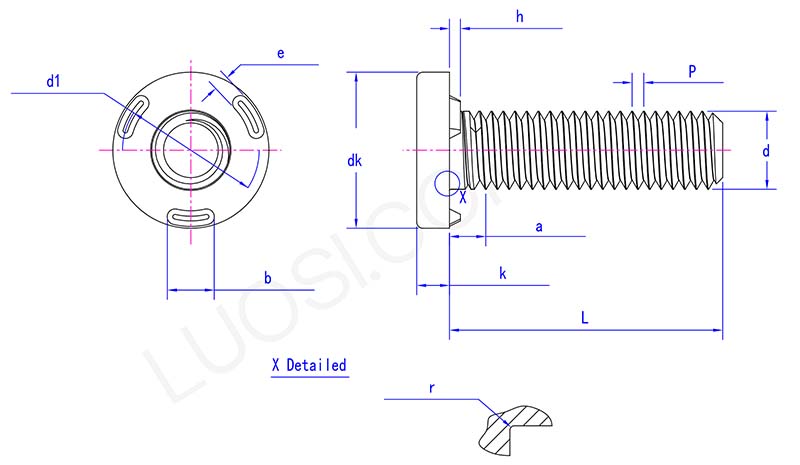

|

Mon |

M5 | M6 | M8 | M10 |

|

P |

0.8 | 1 | 1.25 | 1.5 |

|

dk max |

12.4 | 14.4 | 16.4 | 20.4 |

|

dk min |

11.6 | 13.6 | 15.6 | 19.6 |

|

k max |

2 | 2.2 | 3.2 | 4.2 |

|

k min |

1.6 | 1.8 | 2.8 | 3.8 |

|

e max |

2.25 | 2.75 | 2.25 | 2.75 |

|

e min |

1.75 | 2.25 | 1.75 | 2.25 |

|

b max |

3.3 | 4.3 | 5.3 | 6.3 |

|

b min |

2.7 | 3.7 | 4.7 | 5.7 |

|

h max |

0.8 | 0.9 | 1.1 | 1.3 |

|

h min |

0.6 | 0.75 | 0.9 | 1.1 |

|

d1 max |

10 | 11.5 | 14 | 17.5 |

|

d1 min |

9 | 10.5 | 13 | 16.5 |

|

r min |

0.2 | 0.25 | 0.4 | 0.4 |

|

r max |

0.6 | 0.7 | 0.9 | 1.2 |

|

a max |

3.2 | 4 | 5 | 5 |

The structure of projection underweld screw is very stable. The round head is vertically connected with the screw, forming a tight fit. Under force, it can effectively distribute the pressure and is unlikely to deform or break, ensuring the reliability of the connection. Regular wrenches and other tools can be used for operation. No special equipment is required. Installation and disassembly are relatively easy, making it convenient for later maintenance and adjustment.