Metric Screw For Resistance Projection Welding

Send Inquiry

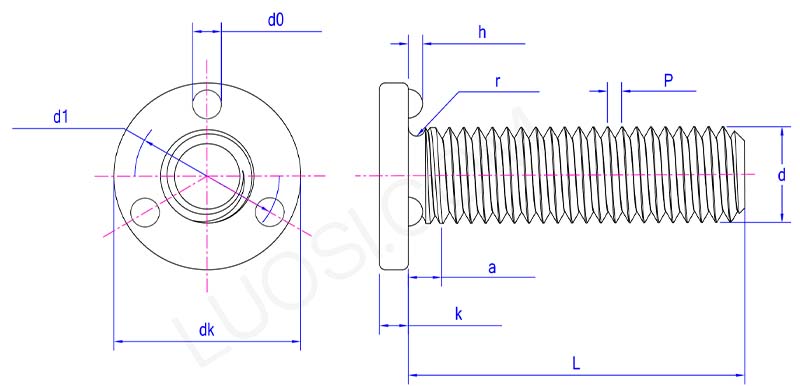

The metric screw for resistance projection welding is mainly composed of a screw body and a head with a special protrusion structure. The screw body part has standard metric threads, which is convenient for matching with corresponding nuts or components with internal threads.

Product parameters

|

Mon |

M3 | M4 | M5 | M6 | M8 | M10 | M12 |

|

P |

0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 |

|

a max |

1.25 | 1.75 | 2 | 2.5 | 3.13 | 3.75 | 4.38 |

|

dk max |

6.37 | 8.45 | 10.45 | 12.55 | 16.55 | 20.65 | 24.65 |

|

dk min |

5.63 | 7.55 | 9.55 | 11.45 | 15.45 | 19.35 | 23.35 |

|

k max |

1.32 | 1.72 | 2.12 | 2.52 | 3.35 | 4.15 | 4.95 |

|

k min |

1.07 | 1.47 | 1.87 | 2.27 | 3.05 | 3.85 | 4.65 |

|

d1 max |

4.98 | 6.48 | 8.08 | 9.58 | 12.7 | 15.7 | 18.7 |

|

d1 min |

4.5 | 6 | 7.5 | 9 | 12 | 15 | 18 |

|

d0 max |

1.15 | 1.45 | 1.75 | 2.05 | 2.65 | 3.25 | 3.9 |

|

d0 min |

0.9 | 1.2 | 1.5 | 1.8 | 2.4 | 3 | 3.6 |

|

h max |

0.55 | 0.7 | 0.85 | 1 | 1.3 | 1.6 | 1.9 |

|

h min |

0.35 | 0.5 | 0.65 | 0.8 | 1.1 | 1.4 | 1.7 |

|

r max |

0.4 | 0.4 | 0.5 | 0.6 | 0.8 | 0.8 | 0.8 |

Product features

The metric screw for resistance projection welding is the unique protrusions on the head. These protrusions have regular shapes and uniform sizes. During welding, they can precisely concentrate the current, ensuring a stable and reliable welding process and significantly enhancing the welding quality. Due to the concentrated force on the protrusions, the welding process has a relatively small thermal impact on other parts of the workpiece.

These metric screws have three small protrusions near the head. Use a welding gun to press them onto the metal. The protrusions will immediately focus the heat, melting the point and causing the screw head to fuse with the surface. This quickly creates a strong, flush-mounted threaded point.

Compared with conventional welding, the projection weld screw require a special welding gun, but it is cleaner / faster than arc welding studs. No need for protective gas or ceramic spacers. The plug-in welding can precisely control the weld points, ensuring consistent results every time.

Metric screw for resistance projection welding can be used for the maintenance doors of HVAC pipelines.Use them for resistance spot welding, which can achieve permanent locking. Weld M4 screws around the opening. Fix the inspection door with a lock washer. The threads will not come loose when the filter is replaced every quarter. Reduce maintenance calls by 90%.