Round Head Projection Weld Screw

Send Inquiry

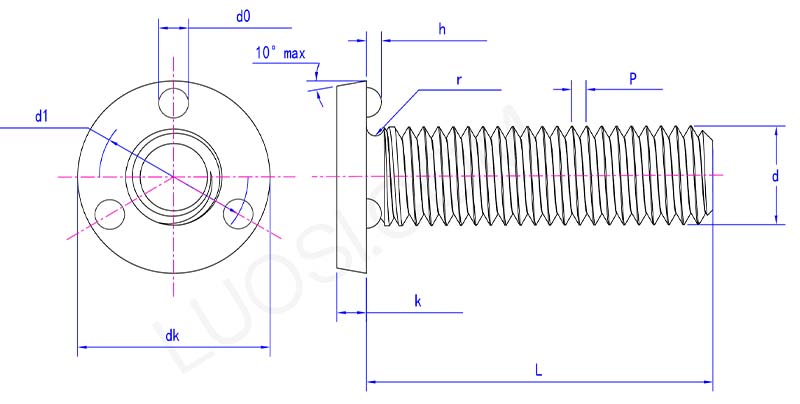

Round head projection weld screws are composed of a threaded rod and a larger-sized flange. The threaded rod part has standard threads and can fit tightly with the matching nut. Compared to the heads of ordinary bolts, it is larger, thicker, usually circular, and has a smooth surface.

Features and applications

The most prominent feature of round head projection weld screw is its strong welding and excellent connection stability. Through the welding process, the bolts can be firmly combined with the weldment, forming a very stable connection, significantly reducing the risk of loosening. Its large flange can increase the contact area with the weldment. When tightening the nut, the pressure can be evenly distributed, avoiding excessive pressure on the surface of the weldment, preventing the weldment from being damaged or deformed.

This weld screw features a flange plate.The shape and size of the flange plate have been meticulously designed, with edges possibly having a certain curvature or special structures. During welding, it can better adhere to the weldment and enhance the welding effect. The thread processing accuracy is high, and it fits tightly with the nut, ensuring the tightening effect after installation. The overall structural design enables the bolt to efficiently transfer the force to the weldment when under stress.

In the automotive manufacturing field, the projection weld screw is widely used. In the production of car chassis, various suspension system components are often fixed with it. For example, when connecting suspension rods, shock absorbers, etc. to the chassis frame, they are first welded to the corresponding positions on the frame, and then the suspension components are installed by using the threads on the bolts.

Round head projection weld screw is used in the manufacturing of kitchen equipment. During the manufacturing process of kitchen equipment, such as large commercial stoves, ovens, dishwashers and other devices, they will be used. For example, when installing components such as the stove frame for commercial stoves and the internal shelves of ovens, by welding them together, these components can be securely fixed to the main body of the equipment.

Product parameters

|

Mon |

M4 | M5 | M6 | M8 | M10 | M12 |

|

P |

0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 |

|

dk max |

11.5 | 12.5 | 14.5 | 19 | 21 | 24 |

|

dk min |

11.23 | 12.23 | 14.23 | 18.67 | 20.67 | 23.67 |

|

k max |

2 | 2.5 | 2.5 | 3.5 | 4 | 5 |

|

k min |

1.75 | 2.25 | 2.25 | 3.25 | 3.75 | 4.75 |

|

r min |

0.2 | 0.2 | 0.3 | 0.3 | 0.4 | 0.4 |

|

d1 max |

8.75 | 9.75 | 10.75 | 14.25 | 16.25 | 18.75 |

|

d1 min |

8.5 | 9.5 | 10.5 | 14 | 16 | 18.5 |

|

h max |

1.25 | 1.25 | 1.25 | 1.45 | 1.45 | 1.65 |

|

h min |

0.9 | 0.9 | 0.9 | 1.1 | 1.1 | 1.3 |

|

d0 max |

2.6 | 2.6 | 2.6 | 3.1 | 3.1 | 3.6 |

|

d0 min |

2.4 | 2.4 | 2.4 | 2.9 | 2.9 | 3.4 |