Single Point Welding Screws

Send Inquiry

The single point welding screws are mainly composed of a screw rod and a head. The screw part has no threads. The head has a special design with a pointed protrusion. This protrusion is specifically designed for welding. Different sizes can meet different usage scenarios.

Product Advantages

The single point welding screws can be fixed with just one concentrated weld. Press it onto the metal, pull the welding gun, and a tiny point will immediately melt, fusing the head of the screw. The process is completed in less than a second. No drilling or nuts are required. Just a single weld is needed for fixation.

The single point weld screw can be used in areas where drill bits cannot reach. It can be used for vertical welding, elevated welding or corner welding. The welding gun can complete the work without worrying about rear contact or gap issues. They can penetrate the metal plate. It can be directly welded to painted metal, galvanized steel or lightly rusted surfaces. This saves cleaning time.

This weld screw can be used in conjunction with a portable welding gun. It can be used to repair truck panels or equipment on-site with a 110V power supply. No heavy welding machine is required; simply plug in the power supply. Good screw fusion will form a small and uniform ring below the screw head. Conduct a torsion test; a firm result indicates success; a rotation result indicates that it needs to be redone.

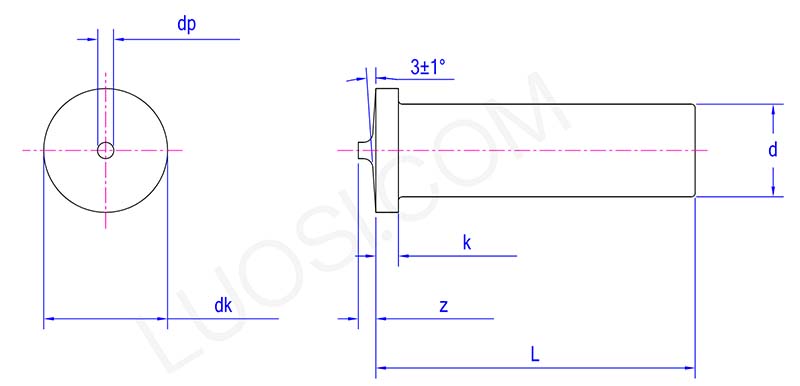

Product Feature And Parameters

The distinctive feature of the single point welding screws is the protrusion at its head. During the welding process, the current can be concentrated at this point, causing the area to heat up quickly and completing the welding operation. This raised shape and size have been precisely designed to ensure the quality of the welding.

|

Mon |

M3 | M4 | M5 | M6 |

|

dk max |

4.7 | 5.7 | 6.7 | 7.7 |

|

dk min |

4.3 | 5.3 | 6.3 | 7.3 |

|

dp max |

0.73 | 0.73 | 0.83 | 0.83 |

|

dp min |

0.57 | 0.57 | 0.67 | 0.67 |

|

z max |

0.6 | 0.6 | 0.85 | 0.85 |

|

z min |

0.5 | 0.5 | 0.75 | 0.75 |

|

k max |

1.4 |

1.4 |

1.4 |

1.4 |

|

k min |

0.7 | 0.7 | 0.8 | 0.8 |