China Square Washers Manufacturer, Supplier, Factory

What Are Square Washers and Why Do They Matter?

Square washers are a fundamental hardware component designed for a secure and stable fit in construction, machinery, and various industrial applications. Unlike standard round washers, square washers feature a flat, square shape that provides a larger surface area. This design helps distribute the load more evenly, preventing bolt or nut heads from digging into the material surface. This is particularly crucial when working with soft materials like wood or when a larger bearing surface is required to maintain structural integrity. Their simple yet effective design makes them an indispensable part of any serious fastener toolkit.

Key Features and Specifications of Our Square Washers

Our square washers are manufactured to the highest standards, ensuring reliability and performance in demanding environments. We use premium materials and rigorous quality control to deliver a product you can trust.

- Material: Manufactured from high-grade, low-carbon steel, providing excellent strength and durability. A corrosion-resistant zinc plating finish is standard for enhanced longevity.

- Surface Finish: A uniform zinc coating offers protection against rust and oxidation, making these washers suitable for both indoor and outdoor applications.

- Precision Engineering: Each washer is stamped and formed with sharp, clean edges and consistent thickness, ensuring a perfect fit and optimal performance.

- Load Distribution: The square shape significantly increases the bearing surface area compared to round washers, reducing surface pressure and preventing material damage.

- Versatility: Ideal for use in woodworking, metal fabrication, automotive repair, and general construction projects.

Detailed Product Specifications

For precise selection and compatibility, refer to the following table for our standard square washer dimensions. All dimensions are in inches and conform to industry standards.

| Washer Size (Nominal Bolt Diameter) | Inside Diameter (ID) | Outside Dimension (A/F) | Thickness |

|---|---|---|---|

| #8 | 0.174" | 0.5" | 0.045" |

| #10 | 0.201" | 0.5" | 0.045" |

| 1/4" | 0.281" | 0.75" | 0.060" |

| 5/16" | 0.344" | 0.88" | 0.075" |

| 3/8" | 0.406" | 1.00" | 0.083" |

| 1/2" | 0.531" | 1.25" | 0.109" |

| 5/8" | 0.656" | 1.50" | 0.134" |

| 3/4" | 0.781" | 1.75" | 0.148" |

Common Applications and Installation Tips

Square washers are the preferred choice in scenarios where a standard round washer might rotate or embed itself into the material. A primary application is in wood construction, where they are often used with carriage bolts. The square neck of the carriage bolt fits securely into the square hole of the washer, preventing the assembly from rotating during tightening. This is essential for framing, deck building, and timber construction. They are also extensively used in metal frameworks, securing heavy machinery, and in electrical installations where a stable, non-rotating base is required.

For correct installation, ensure the square washer is placed between the nut or bolt head and the work surface. The flat sides should sit flush against the material. When used with a carriage bolt, the square hole should fit snugly around the bolt's square section. Always torque the fastener to the manufacturer's recommended specification to achieve the correct clamping force without damaging the washer or the material.

Material and Quality Assurance

The base material for our standard square washers is low-carbon steel, selected for its optimal balance of malleability and strength. The zinc plating process provides a sacrificial layer that actively fights corrosion, significantly extending the service life of the washer, even in mildly humid or outdoor conditions. For more specialized environments, such as those involving high levels of moisture or chemical exposure, optional materials like 304 or 316 stainless steel are available upon request. Our production process includes multiple inspection stages to check for dimensional accuracy, surface defects, and coating uniformity, guaranteeing that every washer that leaves our facility meets stringent quality benchmarks.

Hot Products

Hex Flange Nuts

Hex flange nuts are common hexagonal nuts. The hexagonal shape is convenient for tightening. There is a flange surface on one end of the nut, which is more stable. Xiaoguo® factory always has inventory, available at any time, and supports customization.Standard Hexagon Socket Screw Key

The standard hexagon socket screw key is a tool with standard size for adjusting screws. Different sizes of wrenches can be used according to the different sizes of screws and bolts. The materials used by Xiaoguo® are all in line with the standards, and the products made are sturdy and durable.Black Square Bolts-Forget

China Black square bolts-forget Factory Directly Supply. Baoding Xiaoguo Intelligent Equipment Co., LTD. is a large-scale Black square bolts-forget manufacturer and supplier in China.Our productions cover most of the European and American markets. We look forward to becoming your long-term partner in China.Flanged Anti Loose Nut

For customized Flanged anti loose nut, Xiaoguo® delivers tailored solutions. Whether you need non-standard dimensions or special coatings, our China flanged anti loose nut manufacturers adapt to your specs. The nuts are in stock and ready for urgent orders.Type B Top Seal Retaining Clip

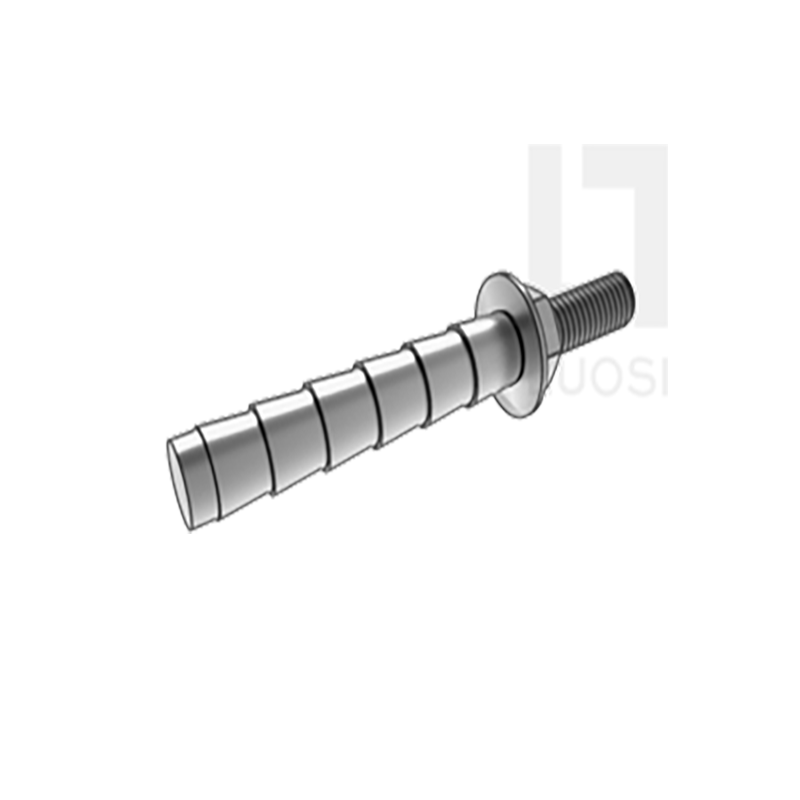

The type B top seal retaining clip is made of durable materials such as metal or plastic and can effectively prevent cards from slipping out.Xiaoguo® maintains strict quality control throughout manufacturing.Self anchoring expansion bolts

Self anchoring expansion bolts can provide durable and stable support. Once inserted into the pre-drilled holes, they will expand by themselves. Xiaoguo® manufacturers offer simple and effective solutions. They comply with the implementation standards of GOST 28778-1990.