Industry Proven Hexagon Weld Nut

Send Inquiry

Good manufacturers of Industry Proven Hexagon Weld Nut follow tight quality controls. They make sure their nuts meet well-known standards like DIN, ISO, or ASTM. This starts with checking that the raw material has the right makeup and strength. Throughout production, they measure the nuts at different steps to keep sizes accurate. After making them, each nut gets examined for flaws—like cracks, bad threads, or uneven weld bumps. Only the ones that pass all the tests are sold.

Product Advantages

How much weight a Industry Proven Hexagon Weld Nut can hold is really important. Its load-bearing capacity depends mainly on three factors: the manufacturing material, the size and specifications, and the quality of the welding process. A strong steel nut with exquisite workmanship can withstand the high axial loads exerted by the bolt.They can also take some side-to-side pressure, though not as much. The hex shape helps too, ‘cause it spreads the force over more surface area. That’s why these nuts are used where keeping things strong and safe really matters.

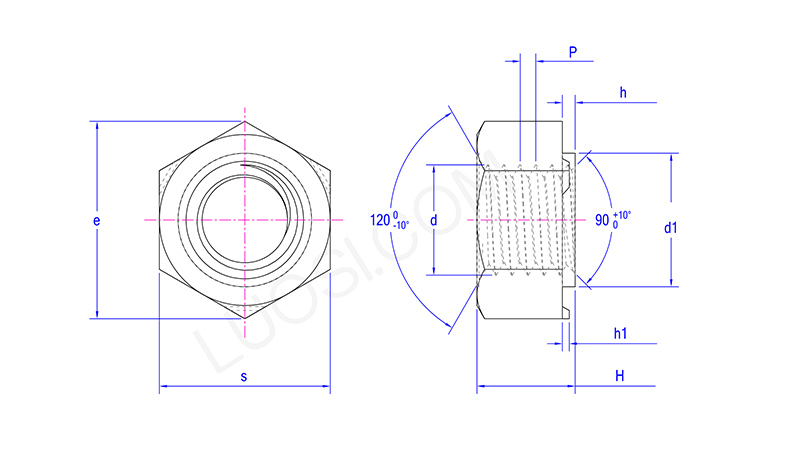

| Mon | M4 | M5 | M6 | M8 | M10 | M12 | M14 | M16 |

| P | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 |

| e min | 9.83 | 10.95 | 12.02 | 15.38 | 18.74 | 20.91 | 24.27 | 26.51 |

| d1 max | 5.97 | 6.96 | 7.96 | 10.45 | 12.45 | 14.75 | 16.75 | 18.735 |

| d1 min | 5.885 | 6.87 | 7.87 | 10.34 | 12.34 | 14.64 | 16.64 | 18.605 |

| h max | 0.65 | 0.7 | 0.75 | 0.9 | 1.15 | 1.4 | 1.8 | 1.8 |

| h min | 0.55 | 0.6 | 0.6 | 0.75 | 0.95 | 1.2 | 1.6 | 1.6 |

| h1 max | 0.35 | 0.4 | 0.4 | 0.5 | 0.65 | 0.8 | 1 | 1 |

| h1 min | 0.25 | 0.3 | 0.3 | 0.35 | 0.5 | 0.6 | 0.8 | 0.8 |

| s max | 9 | 10 | 11 | 14 | 17 | 19 | 22 | 24 |

| s min | 8.78 | 9.78 | 10.73 | 13.73 | 16.73 | 18.67 | 21.67 | 23.67 |

| H max | 3.5 | 4 | 5 | 6.5 | 8 | 10 | 11 | 13 |

| H min | 3.2 | 3.7 | 4.7 | 6.14 | 7.64 | 9.64 | 10.3 | 12.3 |

Q:Are your Industry Proven Hexagon Weld Nuts suitable for automotive applications?

A:Yeah, hex weld nuts are used a lot in making cars. They’re great for holding on body panels, frames, and brackets because they give you a solid threaded spot right on thin metal sheets. They also don’t shake loose easily, which helps keep things like engine mounts tight over time. Since they’re made from strong materials and follow auto industry standards, they’re a common pick for car manufacturing.