Indispensable Hexagonal Wrench

Send Inquiry

The automotive manufacturing industry extensively uses Indispensable Hexagonal Wrench during various maintenance and repair operations. Auto mechanics frequently employ this type of wrench - for instance, when dealing with engine components, adjusting interior trim panels, or repairing the braking system (as these systems often have many Allen bolts). The core performance threshold of high-quality hexagonal wrenches used in automotive repair lies in "strong torsion resistance + high durability" - they must be able to stably withstand the high torque required for repair operations, avoiding bending and breakage problems under stress from the root, and providing dual guarantees for repair efficiency and tool life. This robustness is of utmost importance as it ensures the safety and durability of automotive repair work. That's why both professional auto repair shops and ordinary home repair studios rely on this tool.

Application Scenario

When dealing with precise electronic devices and appliances, precise operation is of utmost importance - and the Indispensable Hexagonal Wrench performs exceptionally well in this regard. People often use it to open the lids of laptops, game consoles, large household appliances, etc., either to repair the device or replace internal parts. A good Indispensable Hexagonal wrench has the right size and smooth edges, so it won't damage the sensitive components inside or those small and fragile screws. Therefore, technicians can maintain the good condition of these expensive devices by performing meticulous work without damaging other components.

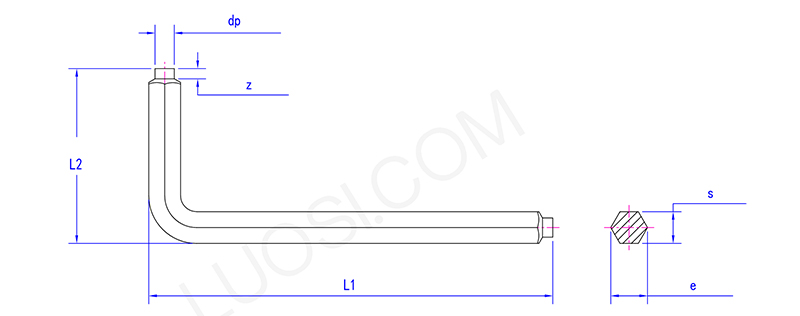

| Mon | 5 | 6 | 8 | 10 | 12 | 14 | 17 | 19 | 22 | 24 | 27 |

| s max | 5 | 6 | 8 | 10 | 12 | 14 | 17 | 19 | 22 | 24 | 27 |

| s min | 4.952 | 5.952 | 7.942 | 9.942 | 11.89 | 13.89 | 16.89 | 18.87 | 21.87 | 23.87 | 26.87 |

| e max | 5.67 | 6.81 | 9.09 | 11.37 | 13.65 | 15.93 | 19.35 | 21.63 | 25.05 | 27.33 | 30.75 |

| e min | 5.58 | 6.71 | 8.97 | 11.23 | 13.44 | 15.7 | 19.09 | 21.32 | 24.71 | 26.97 | 30.36 |

| L1 max | 80 | 90 | 100 | 112 | 125 | 140 | 160 | 180 | 200 | 224 | 250 |

| L1 min | 76 | 86 | 95 | 106 | 119 | 133 | 152 | 171 | 190 | 213 | 238 |

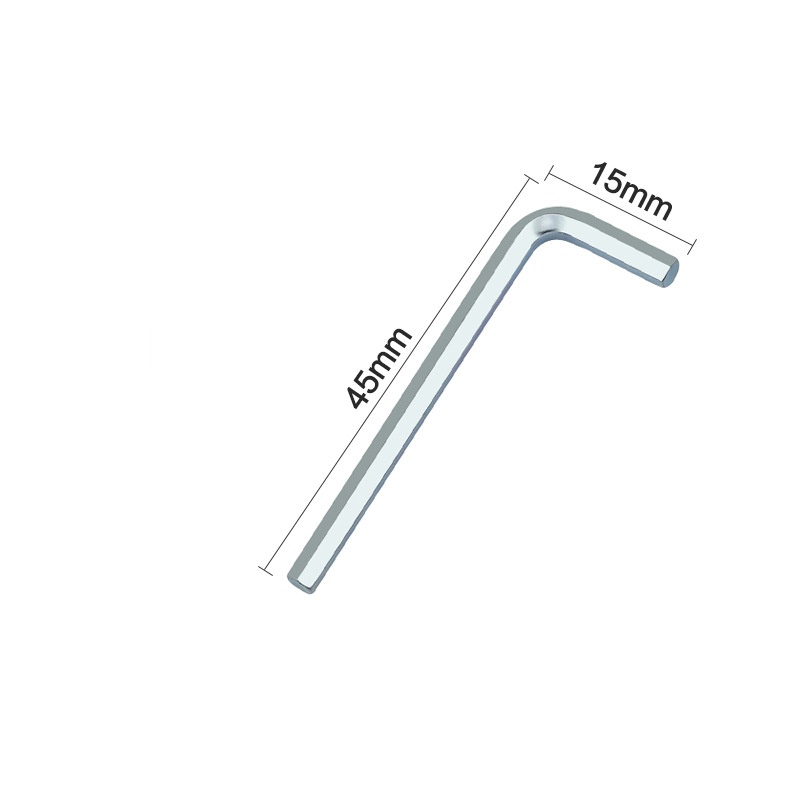

| L2 max | 28 | 32 | 36 | 40 | 45 | 56 | 63 | 70 | 80 | 90 | 100 |

| L2 min | 26 | 30 | 34 | 38 | 43 | 53 | 60 | 67 | 76 | 86 | 95 |

| z max | 1.6 | 2.6 | 2.8 | 3.2 | 3.5 | 3.6 | 4.5 |

5.5 |

6.5 | 6.5 | 8.5 |

| z min | 1.5 | 2.5 | 2.7 | 3.08 | 3.38 | 3.48 | 4.38 | 5.38 | 6.35 | 6.35 | 8.35 |

| dp max | 2.94 | 3.93 | 4.93 | 5.93 | 6.92 | 7.92 | 9.92 | 11.905 | 14.905 | 16.405 | 17.905 |

| dp min | 2.88 | 3.855 | 4.855 | 5.855 | 6.83 | 7.83 | 9.83 | 11.795 | 14.795 | 16.295 | 17.795 |

Excellent product quality

Indispensable Hexagonal Wrench are usually made of several common types of steel: high carbon steel, chromium-vanadium steel or stainless steel.

High-carbon steel is strong enough to handle light-duty work, but special care must be taken during use and storage: if a dry environment cannot be maintained, rust will appear on the surface of the material, so daily moisture-proof and dry maintenance is required. Chromium-vanadium steel is the preferred choice for most people - it is hardened through heat treatment to become strong and durable, with slow wear and suitable for daily tasks such as repairing bicycles or furniture. Stainless steel wrenches do not rust easily, so they are a good choice for outdoor or humid environments, but they are not as strong as chromium-vanadium steel.