China Galvanized Coating Washers Manufacturer, Supplier, Factory

What are Galvanized Coating Washers?

Galvanized coating washers are vital components for corrosion resistance, especially in demanding environments. These washers are typically manufactured from steel and undergo a galvanization process where a protective zinc coating is applied. This coating acts as a barrier against moisture, chemicals, and other corrosive elements, significantly extending the service life of the assembly. They are often used in conjunction with various other fastener types, such as Flat Washers, to distribute load and prevent loosening under vibration. The durability of these washers makes them a preferred choice for outdoor construction, marine applications, and industrial machinery where long-term reliability is non-negotiable. Choosing the right washer, including Flat Washers, is crucial for maintaining structural integrity.

Technical Specifications of Galvanized Coating Washers

The performance of Galvanized Coating Washers is defined by a set of precise technical parameters. These specifications ensure compatibility and reliability in various applications. Key material properties and dimensional standards are detailed below to assist in your selection process.

- Material: Carbon Steel (Grade 1008/1010), Stainless Steel (optional)

- Coating Type: Hot-Dip Galvanized or Electro-Galvanized

- Coating Thickness: Typically 5-25µm (0.2-1.0 mils) for electro-galvanized; 45-85µm (1.8-3.3 mils) for hot-dip.

- Salt Spray Test Performance: Exceeds 72 hours to white rust, 240 hours to red rust for electro-galvanized; over 500 hours for hot-dip.

- Hardness: HRB 70 - 100 (Rockwell B Scale)

- Standards: Compliant with ASTM A153, ASTM B633, ISO 4042, and DIN 267.

| Nominal Size (M) | Inside Diameter (mm) | Outside Diameter (mm) | Thickness (mm) | Approx. Weight per 1000 pcs (kg) |

|---|---|---|---|---|

| M4 | 4.5 | 9.0 | 0.8 | 0.32 |

| M6 | 6.6 | 12.0 | 1.2 | 0.85 |

| M8 | 9.0 | 16.0 | 1.6 | 1.90 |

| M10 | 11.0 | 20.0 | 2.0 | 3.65 |

| M12 | 13.5 | 24.0 | 2.5 | 6.80 |

| M16 | 17.5 | 30.0 | 3.0 | 12.50 |

For specific application requirements not covered in the standard table, custom configurations of Galvanized Coating Washers can be engineered, including variations in zinc coating weight, surface passivation treatments for enhanced corrosion protection, and specific dimensional tolerances.

Hot Products

Screws Eyebolt

Xiaoguo® Screws Eyebolt manufactured in accordance with QC 190 - 2012 standard is a fastener designed for lifting and fixing applications. Screws Eyebolt consists of a threaded rod and a ring head.Double Ended Anchor Studs

Double ended anchor studs are very important for stabilizing the structure. Whether you are building a foundation, installing heavy machinery or industrial equipment, our studs can provide reliable connections. Xiaoguo® manufacturer produces studs that comply with the execution standard of JB/ZQ 4756-2006.Engineered Lifting Eye Nut

Engineered Lifting Eye Nut if you need fasteners for industrial projects, Xiaoguo® has a wide range—from standard steel bolts to specialized aerospace-grade washers, all supplied by trusted manufacturers. This type of fastener features a looped top, designed to attach to heavy objects so they can be lifted safely with tools like cranes or hoists.Rough Flat Head Bolt With Reverse Key

The rough flat head bolt with reverse key has a round flat head and a clear thread on the screw, which is convenient for fastening. When producing fasteners, Xiaoguo® strictly follows the relevant standards and conducts strict testing.Double Head Screw Spike

The double head screw spike produced by Xiaoguo® factory is durable. In the fields of construction and woodworking, they are widely popular for their strong grip. We can send samples for free. You can ask us about the price and we will quote it quickly.Full Thread Hexagon Screws

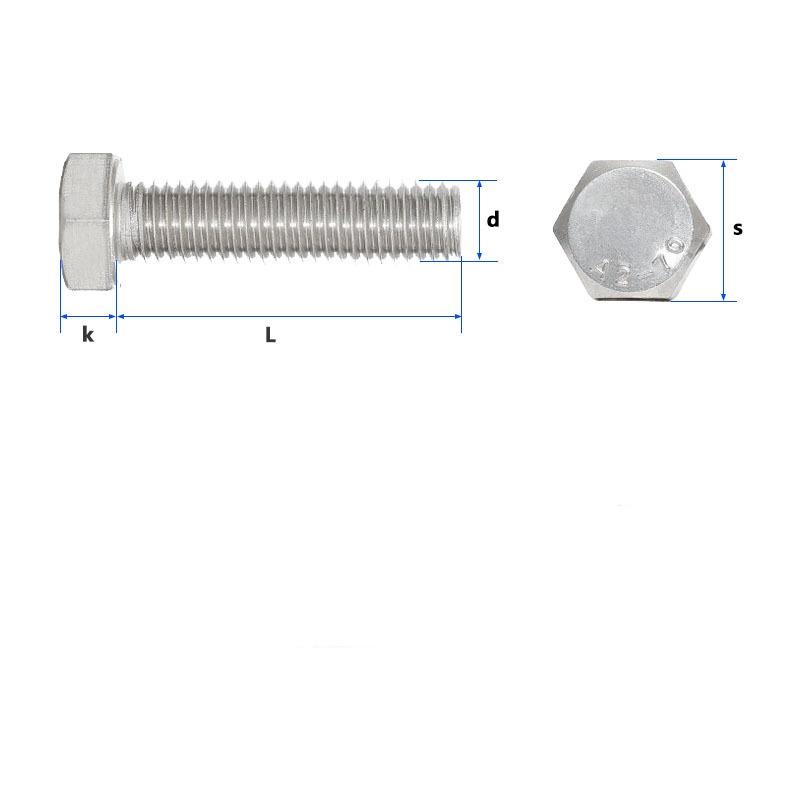

Full Thread Hexagon Screws are characterized by their six-sided head designed for tool engagement. As a professional supplier of industrial fasteners, Xiaoguo® specializes in manufacturing and exporting high-quality ones – including such screws – globally.