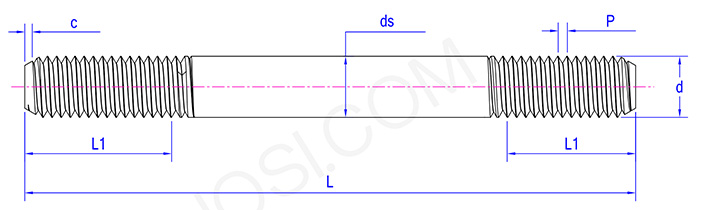

Double Ended Anchor Studs

Send Inquiry

This Double Ended Anchor Studs is mainly used to connect components together, or fasten one component to the base material. For example, on construction sites, you’d use it to fix steel beams to concrete foundations, or mount wall panels on concrete walls. It’s also used in factories to install ceiling brackets. Its double-head design lets you connect from both ends, and it’s usually more stable than single-headed bolts.

In factories, these bolts are often used to attach equipment like motors and water pumps to machine bases or the floor. This way, the equipment won’t shift even when it vibrates a lot. You can also find them in cars and airplanes—like for fixing engine parts, chassis components, or some interior parts that need to be reliable.

They’re also used in large projects such as bridges and tunnels, to fix guardrails, signs, or electrical boxes to concrete or steel structures. On ships, they can secure deck fittings or ship components too. Basically, This Double Ended Anchor Studs is used for practical purposes—just to hold and fasten things firmly in different working conditions.

Product Material

The materials used for double-headed anchor bolts are actually just a few types. It mainly depends on where they are used and the amount of force they will bear. The most commonly used material is carbon steel, which is cost-effective and suitable for use in general indoor or dry areas, such as fixing some non-load-bearing components in factory workshops or for interior decorationMost carbon steel anchor bolts have a zinc coating on the surface, mainly to stop rust.

Stainless steel is also commonly used, especially outdoors, in damp places, or near the sea. It doesn’t rust easily—even if it gets rained on, or comes into contact with moisture, salt fog, etc. So it’s often used in outdoor projects, like bridge guardrails, signs on concrete bases, or some equipment on ships. Usually, 304 or 316 stainless steel is used.Choosing these materials is not about any fancy features; it's simply to ensure that the objects can be securely fixed in different usage scenarios and are durable.

Q&A Session

What material grades are Double Ended Anchor Studs available in, and how to choose based on application scenarios?

A:They are mainly available in 4.8 grade, 8.8 grade, and 12.9 grade. 4.8 grade studs are made of ordinary carbon steel, suitable for light-load indoor applications such as fixing decorative panels or non-bearing components in workshops. 8.8 grade studs are heat-treated alloy steel, with higher tensile strength and hardness, suitable for medium-load scenarios like mounting motors, pumps, or automotive chassis components. 12.9 grade studs are high-strength alloy steel, designed for heavy-load applications such as bridge construction, heavy machinery fixation, or aerospace-related equipment. For high-vibration environments, 8.8 or 12.9 grade Double Ended Anchor Studs are preferred, as they have better fatigue resistance and won’t easily loosen or deform.

Product parameters

| Mon | M24 |

| P | 3 |

| ds max | 26 |

| ds min | 24 |

| c | 5 |

| L1 | 100 |