Introduction to Butterfly Nuts

Butterfly nuts, also known as wing nuts, are a type of fastener designed for quick and easy hand-tightening without the need for tools. They feature two "wings" or projections that allow for a secure grip, making them ideal for applications requiring frequent adjustments or removal, such as in furniture assembly, machinery, and DIY projects. The versatility of butterfly nuts makes them a popular choice across various industries, offering a reliable and reusable fastening solution. If you're looking for a durable option, consider exploring our Wing Nut range, which provides enhanced strength and corrosion resistance for demanding environments. In addition, butterfly nuts are often used alongside other fasteners like Wing Nut components in automotive and construction settings, ensuring efficient assembly and disassembly processes. These nuts are particularly valued for their user-friendly design, which reduces installation time and minimizes the risk of stripping or damage compared to traditional nuts.

Detailed Specifications of Butterfly Nut

Butterfly Nut is engineered to meet high standards of performance and durability, catering to both industrial and consumer needs. Below, we provide a comprehensive overview of its key parameters in both list and table formats to assist in selection and application.

Key Features of Butterfly Nut

- Material: Typically made from stainless steel, zinc-plated steel, or nylon for corrosion resistance and longevity.

- Thread Size: Available in various thread types such as metric (e.g., M6, M8) and imperial (e.g., 1/4"-20, 5/16"-18).

- Wing Span: Ranges from 20mm to 50mm, providing ample leverage for hand-tightening.

- Load Capacity: Designed to withstand moderate to high tensile and shear forces, depending on the material grade.

- Temperature Range: Suitable for environments from -40°C to 120°C, ensuring reliability in diverse conditions.

- Finish Options: Includes electroplating, hot-dip galvanizing, or powder coating for enhanced protection and aesthetics.

Butterfly Nut Parameter Table

| Parameter | Details | Common Applications |

|---|---|---|

| Material | Stainless Steel (Grade 304 or 316), Zinc-Plated Steel, Nylon | Outdoor equipment, marine hardware, electrical enclosures |

| Thread Size | M4 to M12 (metric), #10 to 1/2" (imperial) | Furniture, automotive parts, machinery frames |

| Wing Dimensions | Width: 15-30mm per wing, Thickness: 2-5mm | DIY projects, adjustable fixtures, temporary structures |

| Torque Capacity | 5-25 Nm, varying with material and size | Light to medium-duty fastening in industrial settings |

| Standards Compliance | ISO 4033, DIN 315, ASTM standards | Global manufacturing and construction projects |

This detailed breakdown ensures that Butterfly Nut can be accurately matched to specific requirements, promoting optimal performance and safety in various applications. Always verify compatibility with your project specifications to achieve the best results.

Hot Products

Round Head Eye Bolt

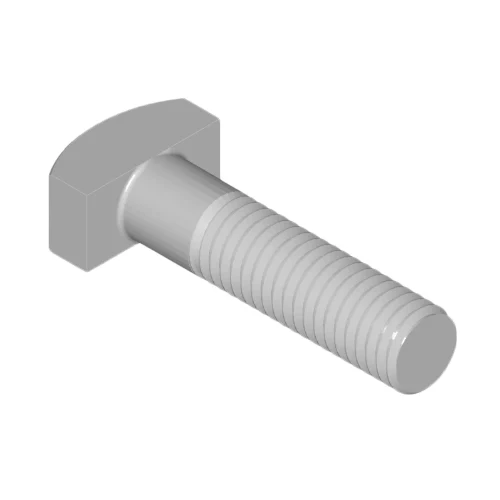

Xiaoguo®is a manufacture specialized in bolts.The head of the Round Head Eye bolt is spherical with holes, the spherical surface is very smooth, it is used with other shafts to play the role of rotation, easy and convenient to install, and the thread precision of the Round Head Eye bolt is relatively high, as a fitting can improve the quality of the overall work piece.T-Head Bolts-Table10

With years of experience in production T- Head Bolts, Baoding Xiaoguo Intelligent Equipment Co., LTD. can supply a wide range of T- Head Bolts. High quality T- Head Bolts can meet many applications, if you need, please get our online timely service about T-Head Bolts-Table10. In addition to the product list below, you can also customize your own unique T- Head Bolts according to your specific needs.Aerospace Validated Aircraft Steel Wire Rope

Aerospace Validated Aircraft Steel Wire Rope is an aviation cable where every batch produced by manufacturer Xiaoguo® undergoes meticulous non-destructive testing and documentation. For any application where failure is not an option, engineers rely on its proven reliability and performance.T Style Weld Nuts With Type 1A

T style weld nuts with type 1A are specifically designed for welding metals and comply with the 1A specification, ensuring a tight fit. Suitable for metal frames, supports or mechanical equipment, the T-shaped design helps to save space. The Xiaoguo® factory has a large quantity of goods in stock.We can also customize and provide products that meet specific needs.Rough Pole Double Studs With Fine Pitch

Rough pole double studs with fine pitch is suitable for scenarios that require high-strength and precise connections. The thick rod enhances the grip, while the fine thread ensures a tight and stable fit. The Xiaoguo® factory has a large amount of inventory in stock.UN Blind hole flat head hexagon riveted nut

Quality control is a fundamental priority at Xiaoguo®.The hexagonal wrenching flats on the UN blind hole flat head hexagon riveted nut allow for secure tool engagement during the riveting installation process.