T Style Weld Nuts With Type 1A

Send Inquiry

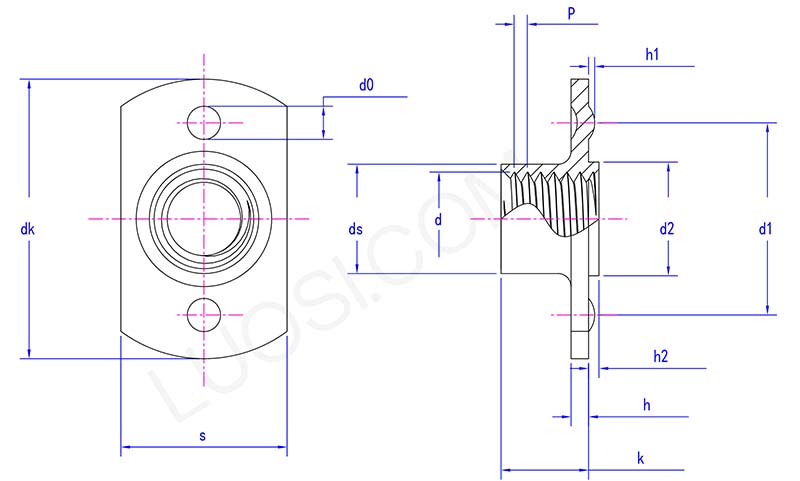

The T style weld nuts with type 1A have a shape resembling the letter "T", with the threaded cylindrical part at the bottom. There are several small protrusions on the flange, which are specifically designed for welding. The common thread specifications range from M4 to M12.

Product parameters

|

Mon |

M4 | M5 | M6 | M8 | M10 | M12 |

|

P |

0.7 | 0.8 | 1 | 1|1.25 | 1.25|1.5 | 1.25|1.75 |

|

dk max |

20.5 | 20.5 | 23.7 | 23.7 | 31 | 33.2 |

|

dk min |

19.5 | 19.5 | 22.3 | 22.3 | 29 | 30.8 |

|

s max |

12.25 | 12.25 | 14.3 | 14.3 | 19.4 | 21.5 |

|

s min |

11.75 | 11.75 | 13.7 | 13.7 | 18.6 | 20.5 |

|

ds max |

5.9 | 6.7 | 8.3 | 10.2 | 13.2 | 15.2 |

|

ds min |

5.4 | 6.2 | 7.8 | 9.5 | 12.5 | 14.5 |

|

k max |

5.9 | 6.9 | 7.5 | 9 | 10.6 | 11.8 |

|

k min |

5.1 | 6.1 | 6.5 | 8 | 9.4 | 10.2 |

|

h max |

1.4 | 1.4 | 1.85 | 1.85 | 2.3 | 2.3 |

|

h min |

1 | 1 | 1.35 | 1.35 | 1.7 | 1.7 |

|

d2 max |

6.9 | 6.9 | 8.9 | 10.9 | 12.9 | 14.9 |

|

d2 min |

6.7 |

6.7 |

8.7 |

10.7 |

12.7 |

14.7 |

|

h2 max |

0.8 |

0.8 |

0.8 |

0.8 |

1.2 | 1.2 |

|

h2 min |

0.6 |

0.6 |

0.6 |

0.6 |

1 | 1 |

|

d0 max |

3.25 |

3.25 |

3.25 |

3.25 |

4.05 | 4.05 |

|

d0 min |

2.75 |

2.75 |

2.75 |

2.75 |

3.55 | 3.55 |

|

h1 max |

0.6 |

0.6 |

0.6 |

0.6 |

0.7 | 0.7 |

|

h1 min |

0.4 |

0.4 |

0.4 |

0.4 |

0.5 |

0.5 |

|

d1 max |

15.2 |

15.2 |

17.25 | 17.25 | 22.3 | 24.3 |

|

d1 min |

14.8 | 14.8 | 16.75 | 16.75 | 21.7 | 23.7 |

Product Features and Installation

The T style weld nuts with type 1A feature a distinctive T-shaped structure. The flange can increase the contact area with the metal plate, distribute the pressure, and make the welding more secure. The size and height of the welding protrusions on the flange are the same, and the heating is uniform during the welding process. Its thread accuracy is high. When the bolt is screwed in, it feels very smooth without any jamming or loosening.

The 1A T-type weld nuts are named for their shape: the hexagonal nut body is eccentrically mounted on the rectangular base plate (flange). The 1A type indicates that it is designed for arc welding (MIG or TIG) around the edge of the flange. The 'T' shape design enables you to position the threaded holes at the desired location, even near the edge where a center nut cannot be installed, and it can be easily achieved.

Installing T style weld nuts of type 1A means to perform welding along the periphery of the rectangular flange. The 1A type nut base is flat and has no holes or protrusions. You can use MIG or TIG to create continuous weld beads along the flange edge. Good overall fusion is crucial as this is the only way to fix the flange. Please thoroughly clean the metal beforehand.

1A T type weld nuts are more expensive than ordinary square nuts. You will have to pay for the processing shape of the flange and additional materials. They also take longer to be correctly welded around the flange. Especially when the thread position needs to be offset, use them; otherwise, standard nuts may be cheaper.